At its core, a Vertical Form Fill Seal (VFFS) machine transforms a flat roll of packaging film into a sealed pouch filled with honey in a continuous, automated process. To handle a viscous product like honey, the machine uses a specialized filling system, typically a servo-driven piston, to accurately dispense the product before the final seal is made. This integration of forming, precise filling, and sealing into one vertical motion is what defines the VFFS method.

The central challenge with packaging honey is managing its high viscosity for a fast, clean, and accurate fill. A properly equipped VFFS machine solves this by combining gentle heating to maintain flow, a powerful piston filler for precise dosing, and an anti-drip nozzle to ensure clean seals.

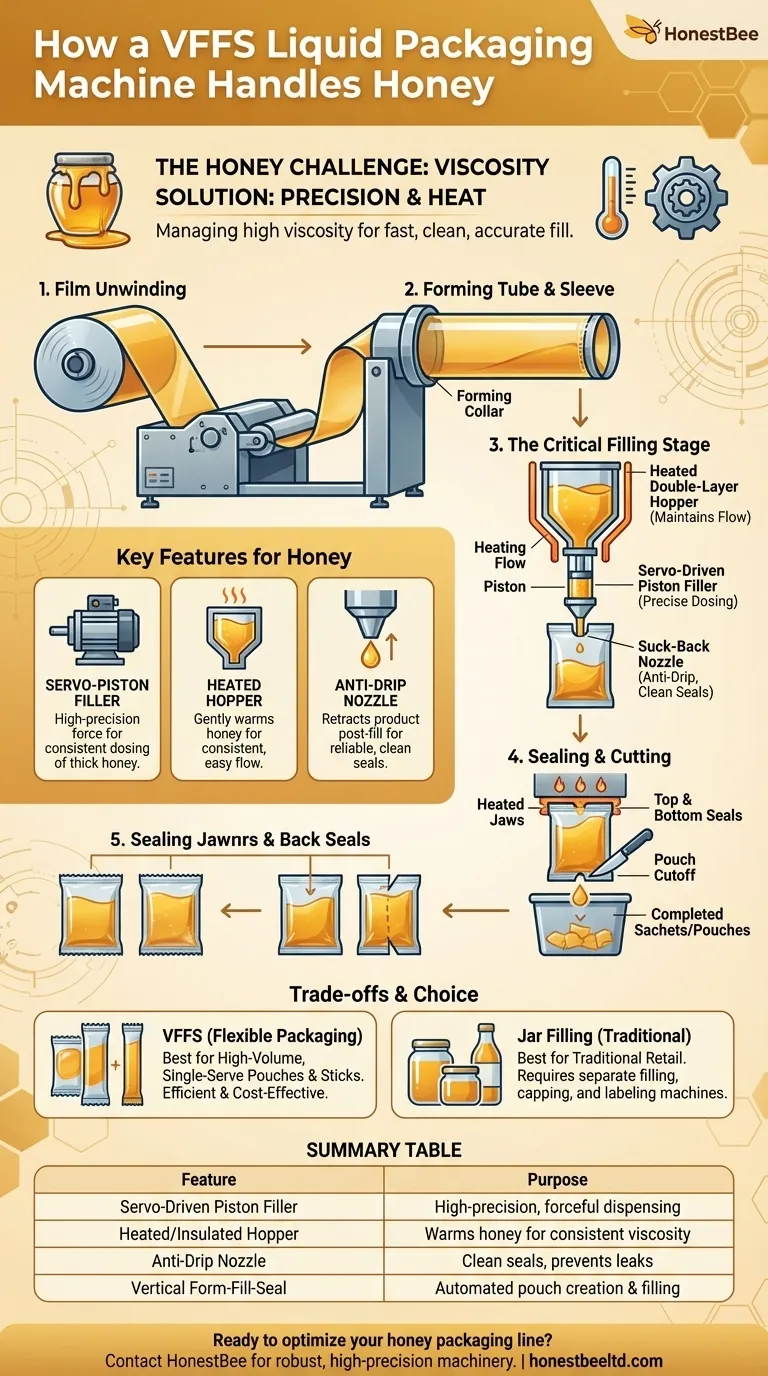

The VFFS Process for Honey: A Step-by-Step Breakdown

A VFFS machine executes a series of synchronized actions to create the final product. Understanding each stage reveals why specific features are critical for handling honey.

Film Unwinding and Forming

The process begins with a large roll of flexible packaging film. The machine unwinds this film and pulls it over a forming tube, often called a forming collar. As the film is drawn down, it is shaped from a flat sheet into a vertical tube. The back of the film is then sealed to create a continuous "sleeve."

The Critical Filling Stage

This is the most crucial step for a viscous product like honey. Once the bottom of the film tube is sealed, the filling apparatus dispenses a precise volume of honey directly into the newly formed pouch. This is typically accomplished with a piston filler, which uses the movement of a piston within a cylinder to draw in and then push out an exact amount of product.

A servo motor is often used to drive this piston. This provides extremely precise control over the filling speed and volume, which is essential for managing a thick liquid like honey and ensuring consistency from one pouch to the next.

Sealing and Cutting

After the honey is dispensed, a pair of heated sealing jaws comes together. These jaws perform two actions simultaneously: they create the top seal of the filled pouch and the bottom seal of the next pouch above it. A knife integrated within the jaws then cuts the completed pouch free, allowing it to drop for collection.

Key Features for Handling Viscous Honey

Standard VFFS machines require specific modifications to run honey efficiently and without creating a mess. These features address the unique physical properties of honey.

The Servo-Driven Piston Filler

This combination is the heart of a honey packaging system. The piston provides the necessary force to move a thick product, while the servo motor provides the intelligence to control the movement with high accuracy. This ensures each sachet receives the correct amount of honey, minimizing waste and maintaining product consistency.

Double-Layer Insulated Hoppers

Honey's viscosity changes significantly with temperature. A double-layer insulated barrel or heated hopper gently warms the honey, keeping it at a consistent, more fluid state. This ensures the honey flows smoothly through the filling system, enabling high-speed, accurate operation without damaging the honey's natural properties.

Anti-Drip and Suck-Back Nozzles

When the filling cycle ends, there is a risk of honey dripping from the nozzle. This stray honey can contaminate the sealing area of the pouch, leading to weak or incomplete seals and a sticky, unprofessional final product.

A suck-back or anti-drip feature retracts a small amount of honey back into the nozzle at the end of each fill. This creates a clean cutoff and ensures the seal area remains completely free of product, guaranteeing a strong, reliable seal every time.

Understanding the Trade-offs

While VFFS technology is powerful, it is designed for a specific type of packaging. Understanding its context is key to making an informed decision.

VFFS for High-Volume Flexible Packaging

VFFS machines excel at producing pouches, sachets, and stick packs at very high speeds. Because the package is formed from a film roll just before filling, it is an extremely cost-effective solution for single-serve portions or other forms of flexible packaging.

Jar Filling for Traditional Retail

In contrast, packaging honey in traditional glass or plastic jars is a different process. This typically involves a standalone piston filling machine that dispenses honey into pre-made containers. This line would then require separate machines for capping and labeling.

The Limitation of Package Format

The primary trade-off is the package itself. A VFFS machine produces flexible pouches, not rigid containers. While ideal for portability and single-use applications, this format may not align with all brand strategies or retail environments, which often favor traditional jars.

Making the Right Choice for Your Goal

Selecting the correct packaging machinery depends entirely on your final product format and production scale.

- If your primary focus is high-speed production of single-serve portions (sachets, sticks): A VFFS machine equipped with a servo-piston filler and heated hopper is the definitive solution for efficiency and cost-effectiveness.

- If your primary focus is packaging for traditional retail in jars or bottles: A dedicated piston filling machine, likely followed by separate capping and labeling stations, is the more appropriate technology.

- If your primary focus is product integrity and accuracy: Regardless of the machine type, insist on features like servo-driven fillers, gentle product heating, and anti-drip nozzles to guarantee a clean and consistent result.

Understanding these core mechanics empowers you to select the technology that best preserves your product's quality and achieves your production goals.

Summary Table:

| Feature | Purpose for Honey Packaging |

|---|---|

| Servo-Driven Piston Filler | Provides high-precision, forceful dispensing of thick honey. |

| Heated/Insulated Hopper | Gently warms honey to maintain consistent, easy-flow viscosity. |

| Anti-Drip Nozzle | Retracts honey post-fill to ensure clean seals and prevent leaks. |

| Vertical Form-Fill-Seal | Automates pouch creation, filling, and sealing in one continuous motion. |

Ready to optimize your honey packaging line?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the robust, high-precision machinery needed for high-volume production. Our expertise ensures you get a VFFS solution tailored to handle viscous products like honey, maximizing your efficiency and protecting your product quality.

Contact our packaging experts today to discuss your specific needs and find the perfect equipment for your operation.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

People Also Ask

- What are the economic benefits of automated honey filling systems? Boost ROI in Large-Scale Commercial Apiaries

- What is the role of automated honey-filling machines in the post-processing of honey products? Boost Brand & Quality

- How does the status of nectar and pollen sources guide the selection of honey filtration and filling equipment?

- What characteristics contribute to the versatility of semi-automatic filling machines? Optimize Your Production Flow

- How does the piston filling principle work in honey filling machines? Achieve Precise, High-Viscosity Filling

- What are equipment used for filling? Match Your Product to the Perfect Filling Machine

- Why are specialized honey filling and packaging machines necessary for forest honey trade? Scale Your Export Business

- How do industrial honey filling machines impact economic efficiency? Scale Your Output and Maximize Profit Margins