At its core, an overflow honey bottle filling machine works by a simple, elegant principle. It fills each bottle to a specific, consistent level rather than by a precise volume. Using a specialized nozzle that creates a seal, it pumps honey into the bottle until the liquid reaches an "overflow" port, at which point any excess honey is suctioned back into the main supply tank for reuse.

The crucial takeaway is that overflow fillers are designed for cosmetic consistency. Their primary purpose is to ensure every bottle on a retail shelf looks identically full, which is vital for brand perception, especially when using clear containers.

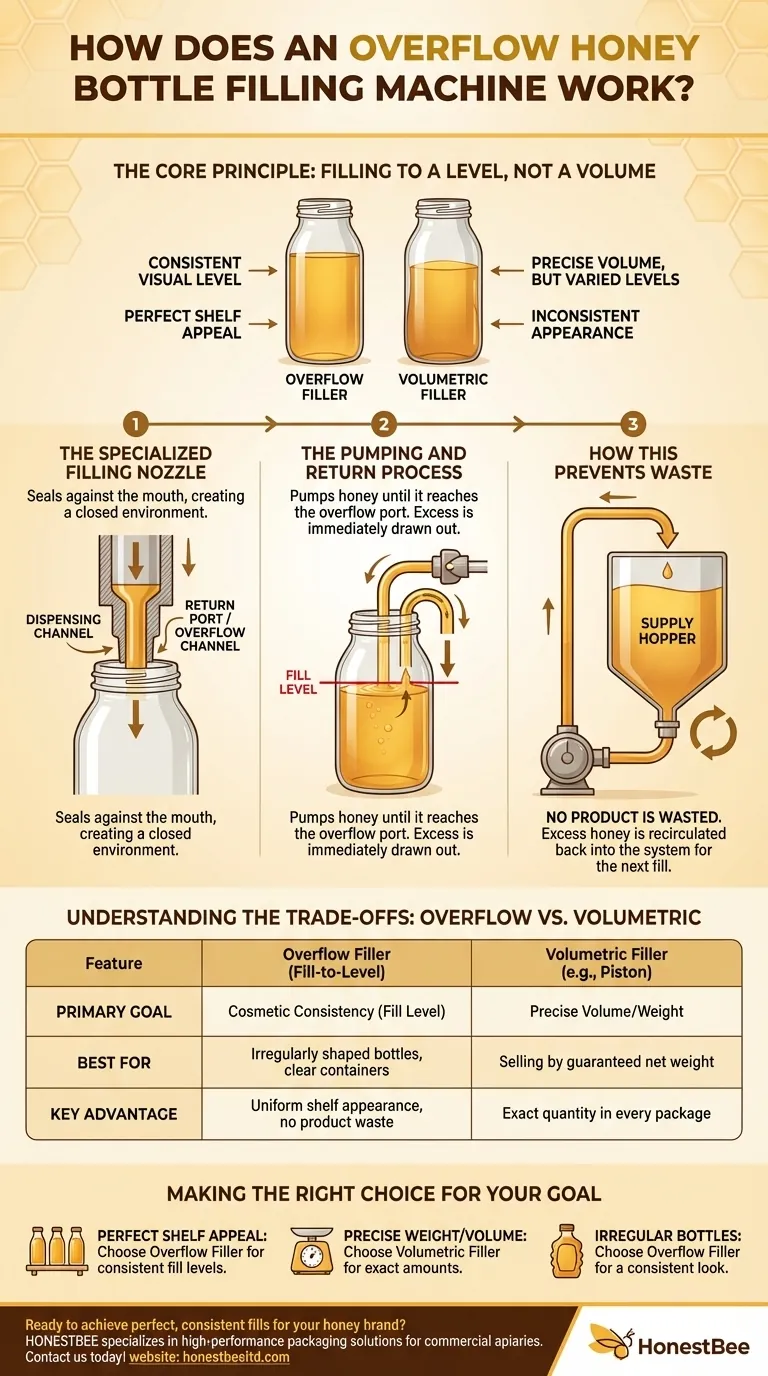

The Core Principle: Filling to a Level, Not a Volume

To understand the machine, you must focus on its unique nozzle design and the concept of recirculation. It's a continuous loop system designed for visual perfection.

The Specialized Filling Nozzle

The nozzle on an overflow filler is the key component. It's designed to seal against the mouth of the bottle, creating a closed environment during the fill.

This nozzle has two primary channels: one for dispensing the honey into the bottle and a second, smaller return port or "overflow" port.

The Pumping and Return Process

As the pump pushes honey into the container, the liquid level rises. Once the honey reaches the opening of the overflow port, the process is complete.

Any additional honey that the pump pushes—along with any trapped air—is immediately drawn out through the return port and sent back to the supply hopper. This action stops the fill at the exact same height in every single bottle.

How This Prevents Waste

The term "overflow" can be misleading. No product is actually wasted or spilled.

The excess honey is simply recirculated back into the system's hopper to be used for the next bottle, creating a clean and highly efficient process.

Understanding the Trade-offs: Overflow vs. Other Fillers

Choosing an overflow filler means prioritizing appearance over exact quantity. This is a critical distinction compared to other common filling technologies.

Overflow Fillers (Fill-to-Level)

These machines excel at providing a uniform look across a product line. They are the ideal solution for irregularly shaped containers or bottles that have minor inconsistencies in their internal volume. A volumetric filler would make these inconsistencies obvious with varying fill heights.

The trade-off is that the actual volume of honey in each bottle may vary slightly. This method is not suitable if you are required to sell by a precise, guaranteed weight or volume.

Volumetric Fillers (Piston & Gravity)

In contrast, machines like piston fillers or gravity fillers are designed for volumetric accuracy. A piston filler uses the stroke of a piston to draw in and then dispense an exact amount of honey. A gravity filler uses valves to control the flow from a hopper for a set period to achieve a target volume.

These are essential when the net weight or volume is the most critical factor. However, if the bottles themselves are not perfectly uniform, the fill levels will appear inconsistent on the shelf.

The Complete Packaging Workflow

The filling process, while crucial, is just one part of the automated packaging line.

From Filling to Sealing

After the bottle is filled to the correct level, it moves on to subsequent stations. The workflow typically ensures the container is immediately capped, sealed, and labeled.

Maintaining Product Purity

Using an integrated machine for the entire process—from filling to sealing—is essential for a food product like honey. It creates a closed, contamination-free workflow that preserves the freshness, quality, and purity of the final product.

Making the Right Choice for Your Goal

The right machine depends entirely on your product's primary requirement: visual appeal or volumetric precision.

- If your primary focus is perfect shelf appeal: An overflow filler is the superior choice because it guarantees a consistent cosmetic fill level in every container.

- If your primary focus is selling by precise weight or volume: A volumetric filler, such as a piston machine, is necessary to ensure each package contains the exact specified amount.

- If your primary focus is handling irregularly shaped bottles: The fill-to-level principle of an overflow machine makes it the only reliable option for achieving a consistent look.

Understanding this fundamental difference between filling to a level versus a volume is the key to selecting the right technology for your packaging goals.

Summary Table:

| Feature | Overflow Filler | Volumetric Filler (e.g., Piston) |

|---|---|---|

| Primary Goal | Cosmetic Consistency (Fill Level) | Precise Volume/Weight |

| Best For | Irregularly shaped bottles, clear containers | Selling by guaranteed net weight |

| Key Advantage | Uniform shelf appearance, no product waste | Exact quantity in every package |

Ready to achieve perfect, consistent fills for your honey brand?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with high-performance, wholesale-focused packaging solutions. Our overflow filling machines are engineered to enhance your brand's shelf appeal and maximize efficiency.

Let us help you select the right equipment for your production goals. Contact our experts today to discuss your needs and get a personalized quote!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- What is the significance of integrating automatic honey filling machines into large-scale apiary operations?

- How does a packaging machine work? A Guide to Form-Fill-Seal vs. Premade Pouch Systems

- What factors should be considered when choosing between semi-automatic and automatic honey filling machines? Optimize Your Honey Production Line

- What are the primary advantages of using automated honey-filling machines? Boost Efficiency and Product Quality

- What are the benefits of using automated honey filling machines? Scale Your Production and Ensure Product Purity

- What are the advantages of industrial automated centrifugal and filling equipment in apiary process improvement?

- How do professional honey packaging and filling equipment enhance the market competitiveness of bee products?

- What role do automated honey-filling machines play in the commercial honey production chain? Scaling Your Output Safely