At its core, the honey stick machine provides the confectionery industry with a highly efficient method for packaging products into convenient, single-serve stick packs. This packaging format is not just for honey; it is a versatile solution for goods like hot chocolate, liquid chewing gums, and candies, enhancing both consumer appeal and operational performance.

The true value of a honey stick machine in confectionery is its ability to bridge the gap between production efficiency and modern consumer demand. It lowers operational costs through automation and minimal material use while creating the portable, easy-to-use products that today's market favors.

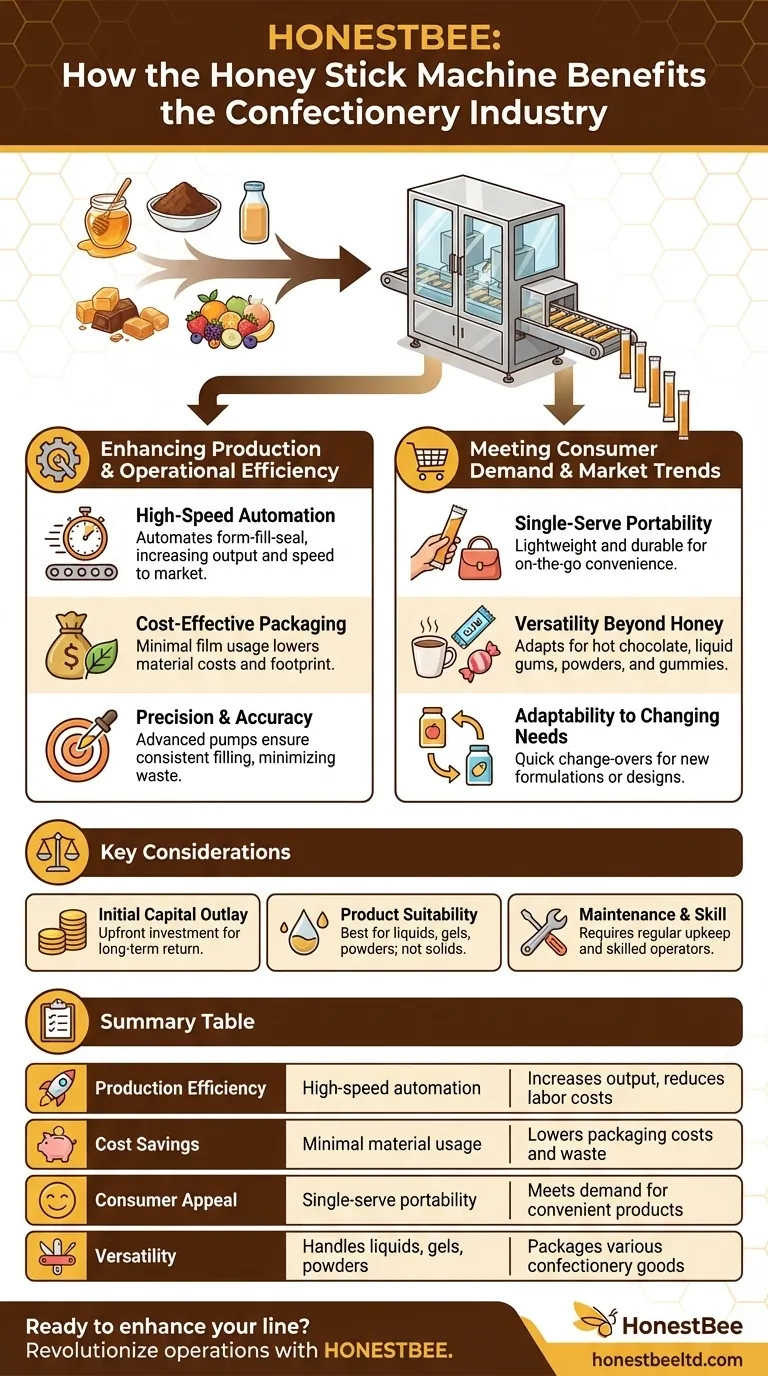

Enhancing Production and Operational Efficiency

A primary benefit of this technology lies in its direct impact on the production line. It introduces automation and precision that streamlines the packaging process from start to finish.

High-Speed Automation

These machines automate the entire form-fill-seal process, significantly increasing packaging speed and overall output. This reduces reliance on manual labor and accelerates the time to market for high-volume products.

Cost-Effective Packaging

The stick pack format is inherently efficient, using a minimal amount of packaging film compared to other single-serve options. This directly translates to lower material costs and a more sustainable packaging footprint.

Precision and Accuracy

Equipped with advanced piston and volumetric pumps, the machine ensures that each stick pack is filled with a precise and consistent amount of product. This accuracy minimizes product waste and guarantees a uniform customer experience.

Meeting Consumer Demand and Market Trends

Beyond the factory floor, the honey stick machine enables manufacturers to produce what consumers increasingly want: convenient, on-the-go products.

The Appeal of Single-Serve Portability

Stick packs are lightweight, durable, and exceptionally easy for end-users to carry and use. This format is ideal for inclusion in lunchboxes, purses, or travel bags, meeting the demand for portable convenience.

Versatility Beyond Honey

While the name suggests a single use, this machine is highly adaptable. In the confectionery industry, it is used for packaging a wide range of products, including hot chocolate mixes, liquid chewing gums, powdered candies, and fruit gummies.

Adaptability to Changing Needs

The equipment offers high flexibility, allowing manufacturers to quickly change between different product formulations or stick pack designs. This agility is crucial for responding to shifting market demands and launching new product variations.

Understanding the Key Considerations

While the benefits are significant, a clear-eyed assessment requires understanding the practical considerations before making an investment.

Initial Capital Outlay

Adopting this automated technology requires an upfront capital investment. The return is realized over time through lower labor costs, reduced material waste, and higher production throughput.

Product Formulation and Viscosity

The machine is optimized for liquids, gels, semi-solids, and fine powders. It is not suitable for packaging solid or chunky confectionery items, which would require a different packaging solution.

Maintenance and Technical Skill

Like any piece of high-performance machinery, a honey stick machine requires regular maintenance and skilled operators to ensure it runs at peak efficiency and avoids costly downtime.

Making the Right Choice for Your Confectionery Business

Integrating a honey stick machine into your operations depends entirely on your strategic goals.

- If your primary focus is launching a new on-the-go product: This machine is the ideal solution for creating the portable, user-friendly stick packs that define this market category.

- If your primary focus is reducing operational costs: The combination of high-speed automation and minimal film usage provides a clear path to lower packaging expenses per unit.

- If your primary focus is increasing production volume: The machine’s automated speed and efficiency can unlock significantly higher throughput compared to manual or semi-automated methods.

Ultimately, this technology empowers confectionery businesses to efficiently produce and package products in a format that aligns perfectly with modern consumer lifestyles.

Summary Table:

| Benefit | Key Feature | Impact |

|---|---|---|

| Production Efficiency | High-speed automation | Increases output, reduces labor costs |

| Cost Savings | Minimal material usage | Lowers packaging costs and waste |

| Consumer Appeal | Single-serve portability | Meets demand for convenient, on-the-go products |

| Versatility | Handles liquids, gels, powders | Packages hot chocolate, candies, and more |

Ready to enhance your confectionery packaging line?

As HONESTBEE, we specialize in supplying robust, high-performance beekeeping and packaging equipment to commercial apiaries and distributors. A honey stick machine can revolutionize your operations by automating packaging, reducing costs, and creating the portable products your customers want.

Let us help you boost your production efficiency and meet market trends. Contact our experts today to find the perfect solution for your business!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

People Also Ask

- How do industrial-grade honey-filling machines preserve the antibacterial properties of honey? Safeguard Bioactivity

- What are the advantages of using high-precision honey filling machines? Optimize Your Commercial Honey Production

- What are the different types of honey filling machines? Choose the Right Equipment for Your Apiary

- What advantages do automatic honey-filling machines provide? Boost Efficiency for Beekeeping Cooperatives

- How do automated honey-filling machines demonstrate process advantages? Boost Efficiency & Hygiene for Your Apiary

- What is the filling accuracy of the automatic dosing and bottling device? Boost Precision and Reduce Product Waste

- What auxiliary machines are used with honey fillers? Build a Complete, Automated Packaging Line

- What are the disadvantages of volumetric filling machines? Key Drawbacks for Your Packaging Line