At its core, a honey-wax separating screw press is a mechanical device that uses immense pressure to physically squeeze wax cappings. This action efficiently separates the cappings into two distinct streams: clean, liquid honey and compressed, nearly dry beeswax, enabling a continuous and highly efficient workflow.

The fundamental advantage of a screw press is its ability to replace slower, batch-based separation methods with a continuous, cold-press system. This maximizes honey yield and preserves its quality while making wax processing far more manageable.

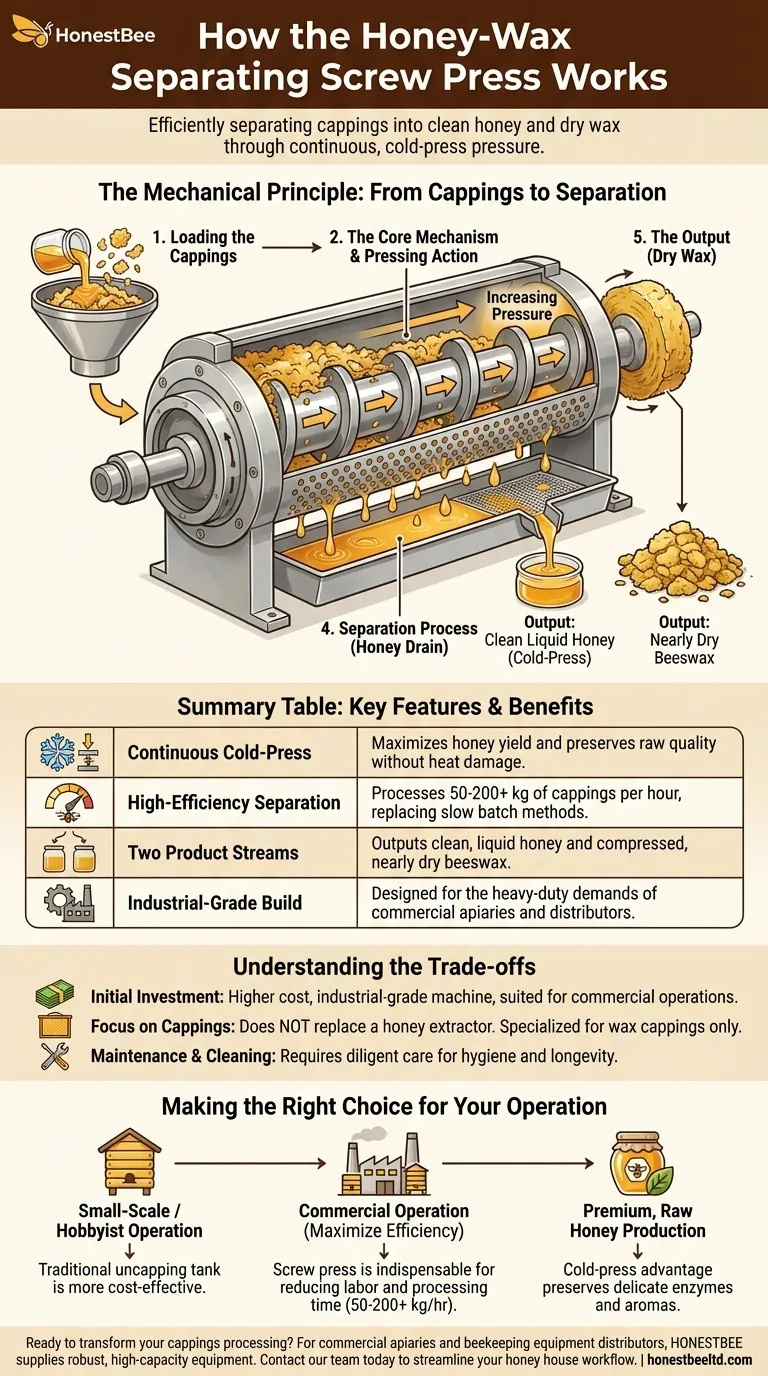

The Mechanical Principle: From Cappings to Separation

To understand the value of a screw press, it's essential to visualize its internal mechanics. The process is straightforward but powerful, relying on simple physics to achieve a clean separation.

The Input Stage: Loading the Cappings

The process begins when a mixture of wax cappings and the honey they contain is fed into the machine, typically through a hopper at one end. This mixture is the direct byproduct of slicing the wax caps off honeycomb frames before extraction.

The Core Mechanism: The Screw and Cylinder

The central components are a powerful rotating screw (often called an auger) housed inside a durable, perforated cylinder. This design is the heart of the machine's function.

The Pressing Action

As the screw turns, it simultaneously moves the cappings along the length of the cylinder. The design of the screw and the cylinder creates progressively increasing pressure on the cappings as they are pushed forward.

The Separation Process

This immense pressure forces the liquid honey through the small orifices in the perforated cylinder wall. The honey drains down, often passing through an additional sieve underneath for immediate fine-filtering.

The Output: Dry Wax and Clean Honey

The compressed beeswax, now with most of the honey removed, continues its journey to the end of the screw, where it is expelled as a dense, dry puck or crumble. The result is two separate, valuable products from what was once a single, messy mixture.

Understanding the Trade-offs

While highly effective, a screw press is a specialized piece of equipment. Understanding its context is key to appreciating its role.

Initial Investment

These are robust, often industrial-grade machines. Their cost is significantly higher than simpler methods like uncapping tanks, making them a primary consideration for commercial or serious sideline beekeeping operations.

Focus on Cappings

It is critical to understand that a screw press does not replace a honey extractor. Its sole purpose is to process the wax cappings, not the honeycomb frames themselves. It is a complementary tool in the honey house workflow.

Maintenance and Cleaning

As with any food-grade mechanical equipment, a screw press requires diligent cleaning and maintenance. Proper care is essential to ensure honey hygiene and the machine's longevity.

Making the Right Choice for Your Operation

A screw press is a powerful tool, but its suitability depends entirely on the scale and goals of your honey production.

- If your primary focus is a small-scale or hobbyist operation: Traditional methods using a simple uncapping tank to drain cappings over time are far more cost-effective.

- If your primary focus is maximizing efficiency in a commercial operation: A screw press is an indispensable asset that dramatically reduces labor and processing time, handling capacities of 50 to over 200 kg per hour.

- If your primary focus is producing premium, raw honey: The cold-press nature of the machine is a significant advantage, as it separates the honey without applying heat that could damage delicate enzymes and aromas.

Ultimately, the screw press provides a definitive solution for transforming the challenge of honey-laden cappings into an efficient, high-yield process.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Continuous Cold-Press | Maximizes honey yield and preserves raw quality without heat damage. |

| High-Efficiency Separation | Processes 50-200+ kg of cappings per hour, replacing slow batch methods. |

| Two Product Streams | Outputs clean, liquid honey and compressed, nearly dry beeswax. |

| Industrial-Grade Build | Designed for the heavy-duty demands of commercial apiaries and distributors. |

Ready to transform your cappings processing? For commercial apiaries and beekeeping equipment distributors, HONESTBEE's wholesale-focused operations supply the robust, high-capacity equipment you need to maximize efficiency and honey quality. Contact our team today to discuss how our honey-wax separating screw presses can streamline your honey house workflow.

Visual Guide

Related Products

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Professional Extra-Wide Uncapping Fork with Bent Tines for Beekeeping

People Also Ask

- What is the cleaning procedure for a stainless steel honey press? Ensure Food Safety with These Pro Cleaning Steps

- What is the mechanism of action for a manual Honey Presser? Maximize Your Yield in Transitional Beekeeping

- What is the pressing method of honey? Preserve Flavor & Quality with Traditional Extraction

- What is the advantage of the long handle on the honey press? Unlock Effortless Extraction with Minimal Force

- Can the Honey Press be used for purposes other than honey extraction? Unlock Its Versatility for Juicing & Herbal Projects

- Why is a honey press considered efficient and effective? Maximize Yield for Small-Scale Beekeeping

- How does a honey press work? A Guide to Simple, High-Yield Honey Extraction

- How does the honey separation and pressing process work in the Wax Screw Presses set? Maximize Honey Yield from Cappings