To prepare a wooden paddle for making wax foundation, it must be made of hardwood and soaked in water for several hours. Immediately before dipping, it is submerged in water again and shaken to remove excess droplets. This ensures the wood is completely saturated, which is the critical factor for success.

The core challenge in making wax foundation sheets is preventing the hot, liquid wax from permanently sticking to the dipping board. The solution is simple yet essential: using a thoroughly water-soaked paddle creates a natural release layer, allowing the cooled wax sheet to be peeled off cleanly.

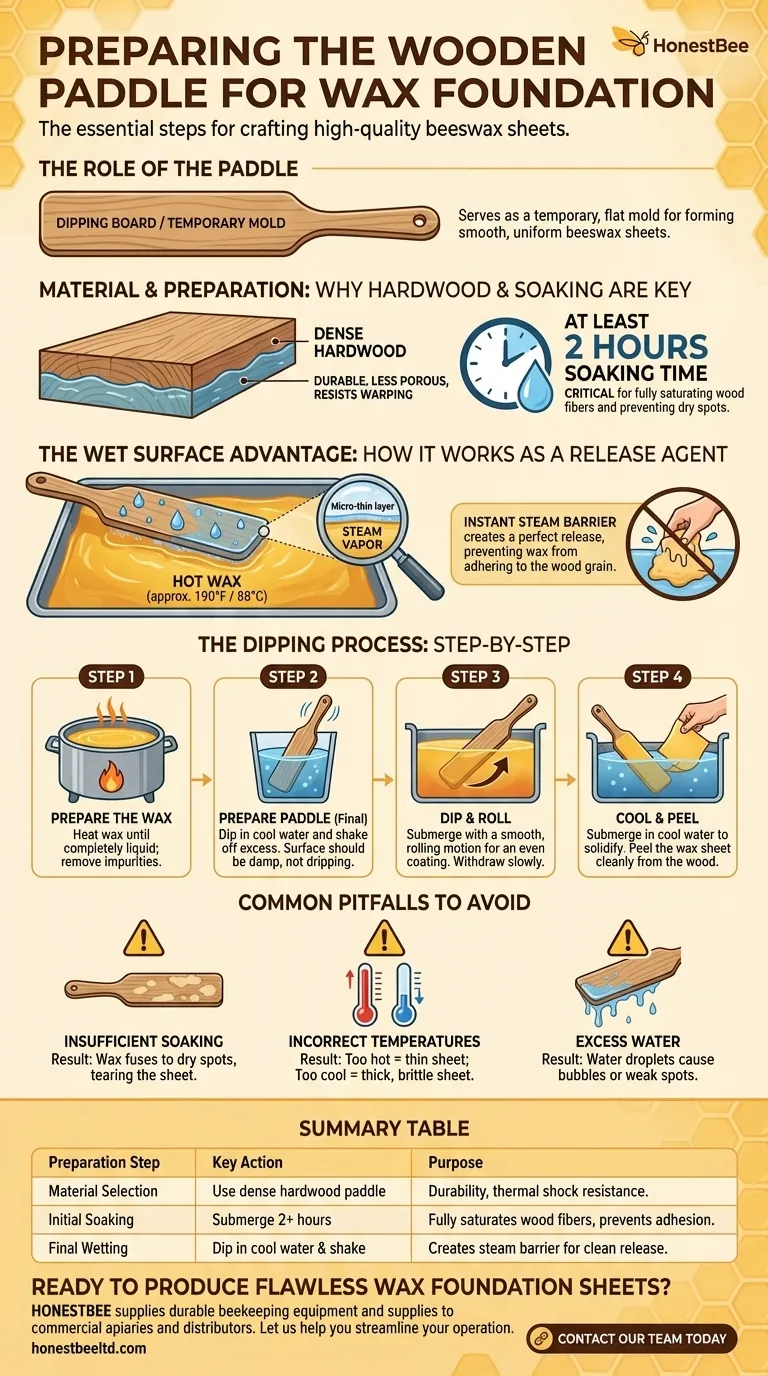

The Role of the Paddle in Foundation Making

The wooden paddle, often called a dipping board, serves as a temporary, flat mold. Its preparation is not just a preliminary step; it is fundamental to the entire process of forming a smooth, uniform sheet of beeswax.

Why Hardwood is Used

The paddle is typically made from a dense hardwood. This is because hardwood is durable, less porous than softwood, and far more resistant to warping or cracking when repeatedly subjected to the thermal shock of moving between hot wax and cool water.

The Critical Soaking Step

Soaking the paddle in water for at least two hours is the most important preparation task. This allows the wood fibers to become fully saturated with water. An incompletely soaked board will have dry spots where the wax can penetrate and bond.

How a Wet Surface Functions as a Release Agent

When the cool, wet paddle is submerged in hot wax (often around 190°F or 88°C), the water on its surface instantly creates a micro-thin layer of steam. This vapor barrier acts as a perfect release agent, preventing the wax from adhering directly to the wood grain. This is the same principle as wetting your hands to handle sticky rice or dough.

The Dipping Process: A Step-by-Step Breakdown

Preparing the paddle is one part of a precise, temperature-sensitive operation. Understanding the full context ensures a better result.

Step 1: Prepare the Wax

Before dipping begins, the beeswax must be heated in a vat until it is completely liquid and clean. Impurities are often allowed to settle at the bottom overnight, ensuring only pure wax is used for the foundation sheets.

Step 2: Prepare the Paddle for Dipping

Just before use, the pre-soaked paddle is dipped into a container of cool water and then lifted out. A quick shake removes excess water, leaving the surface uniformly damp but not dripping.

Step 3: Dip the Paddle into the Wax

The damp paddle is submerged into the hot wax using a smooth, rolling motion. This ensures an even coating. It is held for a moment and then withdrawn, allowing excess wax to drip back into the vat. The thickness of the final sheet is controlled by the number of dips.

Step 4: Cool and Remove the Wax Sheet

After dipping, the paddle with its new wax coating is often submerged in a cool water bath to rapidly solidify the sheet. Because the paddle was wet, the finished wax sheet can then be easily and cleanly peeled away from the wood.

Common Pitfalls to Avoid

Success depends on avoiding a few common mistakes related to the paddle and its environment.

Insufficient Soaking Time

If the paddle is not soaked long enough, it will have dry patches. Wax will fuse to these dry spots, making it impossible to remove the sheet without tearing it and requiring you to scrape the board clean.

Incorrect Temperatures

The process is a delicate balance of temperatures. If the wax is too hot, the sheet will be too thin. If it is too cool, the sheet will be thick, lumpy, and brittle. The water used for wetting the paddle should be cool to maximize the temperature difference.

Excess Water on the Paddle

While wetness is key, a paddle that is dripping with water can introduce imperfections. The water droplets can cause bubbles or weak spots in the finished wax sheet, so shaking off the excess is an important final gesture.

Making the Right Choice for Your Process

Your specific goal will determine where you focus your attention.

- If your primary focus is a perfect, clean release: Ensure the paddle is made of dense hardwood and is fully saturated by soaking for several hours before you begin.

- If your primary focus is creating uniform, high-quality sheets: Pay close attention to maintaining a consistent wax temperature and developing a smooth, repeatable dipping technique.

Mastering the simple preparation of the dipping board is the foundation for successfully crafting your own beeswax sheets.

Summary Table:

| Preparation Step | Key Action | Purpose |

|---|---|---|

| Material Selection | Use a dense hardwood paddle. | Durability and resistance to warping from thermal shock. |

| Initial Soaking | Submerge paddle in water for at least 2 hours. | Fully saturates wood fibers to prevent wax adhesion. |

| Final Wetting | Dip in cool water and shake off excess just before use. | Creates a steam barrier for a clean release from hot wax. |

Ready to produce flawless wax foundation sheets? The right equipment is crucial for efficiency and quality. HONESTBEE supplies durable beekeeping equipment and supplies to commercial apiaries and distributors. Let us help you streamline your operation with our wholesale-focused solutions. Contact our team today to discuss your needs!

Visual Guide

Related Products

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Manual Spur Wheel Wire Embedder for Foundation

- Stainless Steel Dual Blade Uncapping Plane

- All-Stainless Steel Pivoting Honey Uncapping Fork for Beekeeping

- Professional Honey Uncapping Fork Tool with Customizable Tine Options

People Also Ask

- What is the purpose of using natural beeswax foundation in honeybee larval host selection? Key to Ecological Validity

- What is the function of installing new wax foundation in frames? Build a Productive Apiary with Precise Architecture

- Why must the wax foundation be defined for Liebefeld cell counts? Precision Tools for Accurate Colony Metrics

- Why is wax foundation used as a critical production consumable? Boost Honey Yields and Hive Efficiency

- How do Dadant Beehives with Wax Foundations assist in colony management? Boost Hive Performance and Growth

- How can you make medium or shallow foundation sheets with a deep foundation mold? Maximize Your Beekeeping Mold Utility

- What is the primary function of standard beeswax foundations? Boost Hive Efficiency and Structural Integrity

- What should a beekeeper do if they notice a lack of beeswax in a hive? Guide to Hive Repair & Beeswax Sourcing