The standard method for strengthening beeswax foundation is to embed reinforcing wires into it before the bees draw out the comb. This is most effectively done by passing a low-voltage electric current through horizontal wires, causing them to heat up and melt seamlessly into the wax sheet. This process creates a durable internal skeleton for the comb.

The core problem is that natural wax comb is fragile, prone to breaking under the centrifugal force of honey extractors or the sheer weight of honey in warm weather. Embedding wires acts like rebar in concrete, providing the necessary tensile strength to keep the comb intact for years of use.

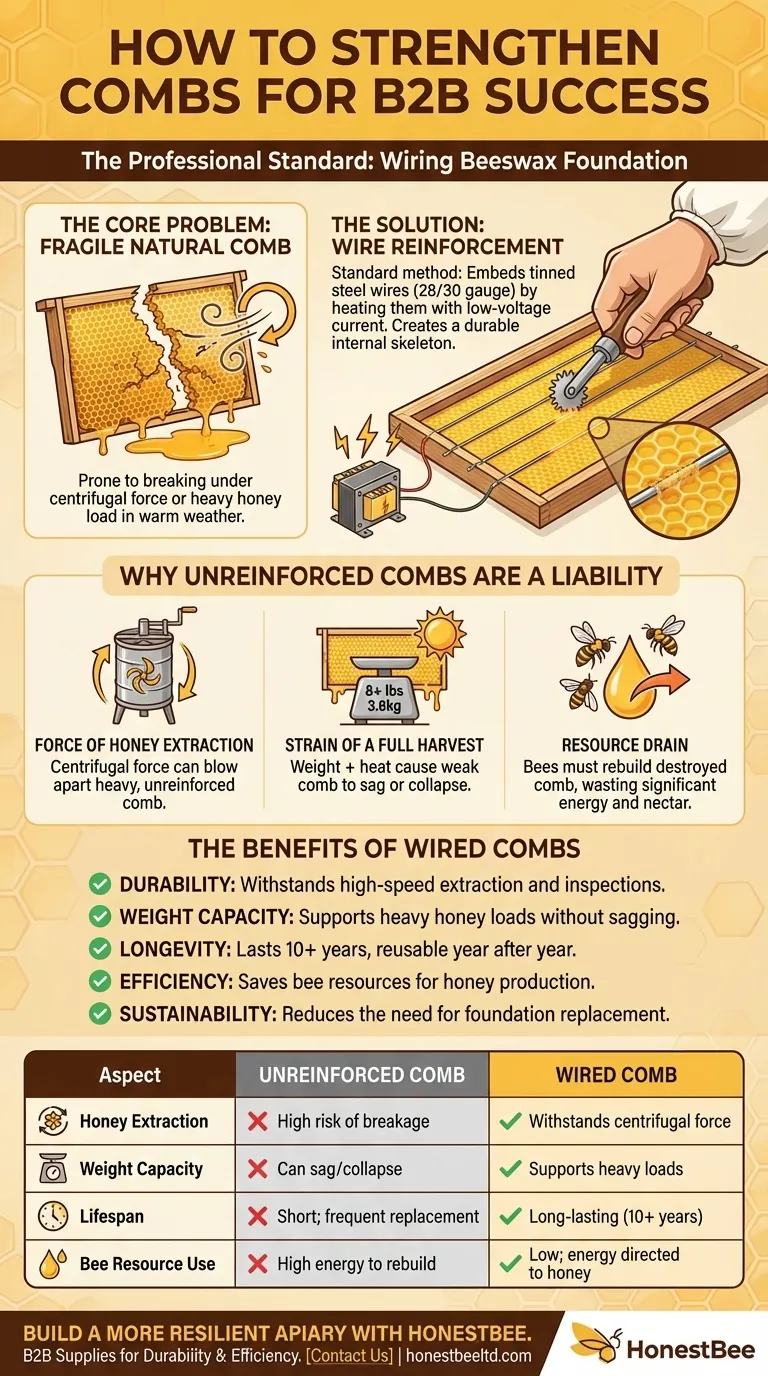

Why Unreinforced Combs Are a Liability

A comb is the fundamental structure of the hive, used for both raising brood and storing honey. Its structural integrity is not just a convenience; it is critical to the productivity and management of the colony.

The Force of Honey Extraction

The primary reason for reinforcing comb is to withstand honey extraction. Extractors use centrifugal force to spin honey out of the cells. An unreinforced comb, especially one heavy with honey, can easily blow apart, ruining the comb and contaminating the harvest.

The Strain of a Full Harvest

A deep frame full of honey can weigh over eight pounds (3.6 kg). In the heat of summer, beeswax softens considerably. This combination of weight and heat can cause a weak comb to sag, stretch, or even collapse entirely within the hive.

Longevity and Hive Resources

When a comb is destroyed, the bees must expend significant energy and resources (nectar) to rebuild it. A properly wired comb can be extracted and returned to the bees for refilling year after year, saving the colony immense effort that can be redirected toward producing more honey.

The Principle of Wire Reinforcement

Embedding wire into the foundation creates a single, cohesive unit. The wire provides the tensile strength that wax lacks, while the wax provides the structure that bees build upon.

The Critical Components

- Frame & Foundation: The process starts with a standard wooden hive frame. A sheet of beeswax or plastic foundation, imprinted with the hexagonal cell pattern, is placed inside it.

- Wire: Tinned steel wire, typically 28 or 30 gauge, is strung horizontally through holes drilled in the frame's side bars.

- Embedding Tool: A small transformer or a spur wire embedder is used. These devices supply a low-voltage current that is safe to work with but sufficient to heat the wire.

The Embedding Process

The wires are first strung and tensioned across the frame, resting on top of the foundation sheet. The terminals from the power source are then touched to the ends of each wire.

The electric current heats the wire almost instantly. This heat melts the wax directly beneath the wire, allowing it to sink a few millimeters into the foundation. Once the current is removed, the wax cools and solidifies around the wire, locking it permanently in place.

Understanding the Trade-offs

While wiring is the professional standard for durable combs, it's important to understand the investment it requires.

The Primary Benefit: Durability

The advantages are significant. Wired combs can withstand high-speed extraction, are less likely to be damaged during hive inspections, and can last for a decade or more. This dramatically increases the efficiency of a beekeeping operation.

The Initial Investment: Time and Equipment

The main drawback is the upfront labor. Wiring frames is a time-consuming task, especially for large operations. It also requires a small investment in an embedding tool.

A Common Pitfall: Improper Embedding

If the wire is not heated enough, it won't sink properly and may sit on the surface. Conversely, if it's heated for too long, it can melt all the way through the foundation. Finding the right, brief application of current is key to a perfect embed.

Making the Right Choice for Your Goal

Your approach to comb reinforcement should align with the scale and goals of your beekeeping.

- If your primary focus is maximum honey production and efficiency: Wiring your frames is non-negotiable. It allows for fast extraction and minimizes comb loss.

- If your primary focus is long-term sustainability and reducing costs: Investing the time to wire frames creates a durable, reusable asset that saves bee energy and reduces the need for foundation replacement.

- If you are a small-scale hobbyist who prioritizes natural comb: You can use foundationless frames, but you must accept the high risk of comb breakage during extraction and handling.

Ultimately, reinforcing your combs is a foundational investment in building a more resilient and productive apiary.

Summary Table:

| Aspect | Unreinforced Comb | Wired Comb |

|---|---|---|

| Honey Extraction | High risk of breakage | Withstands centrifugal force |

| Weight Capacity | Can sag or collapse when full | Supports heavy honey loads |

| Lifespan | Short; needs frequent replacement | Long-lasting (10+ years) |

| Bee Resource Use | High energy to rebuild | Low; energy directed to honey production |

Build a more resilient and productive apiary with HONESTBEE.

As a leading wholesale supplier to commercial apiaries and distributors, we understand that comb breakage means lost time and lost revenue. Our high-quality beekeeping supplies, including durable frames, foundation, and embedding tools, are designed for maximum durability and efficiency.

Let us help you strengthen your operation from the comb up. Contact our team today to discuss your needs and discover how our equipment can protect your harvest and boost your bottom line.

Visual Guide

Related Products

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Spur Wheel Wire Embedder for Foundation

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What is the purpose of bee frame wire? Secure Wax Foundation and Reinforce Honeycomb

- Why are hot wires or specialized cutting tools required for Top Bar Hive comb management? Master Hive Structural Integrity

- What are the functions of wire-tensioning tools and wax foundation installation equipment in frame pretreatment?

- What methods are used to embed wire into the foundation? A Guide to Stronger, More Durable Beehives

- How does the frame wiring jig assist in running horizontal wires through frames? Streamline Your Beekeeping Setup