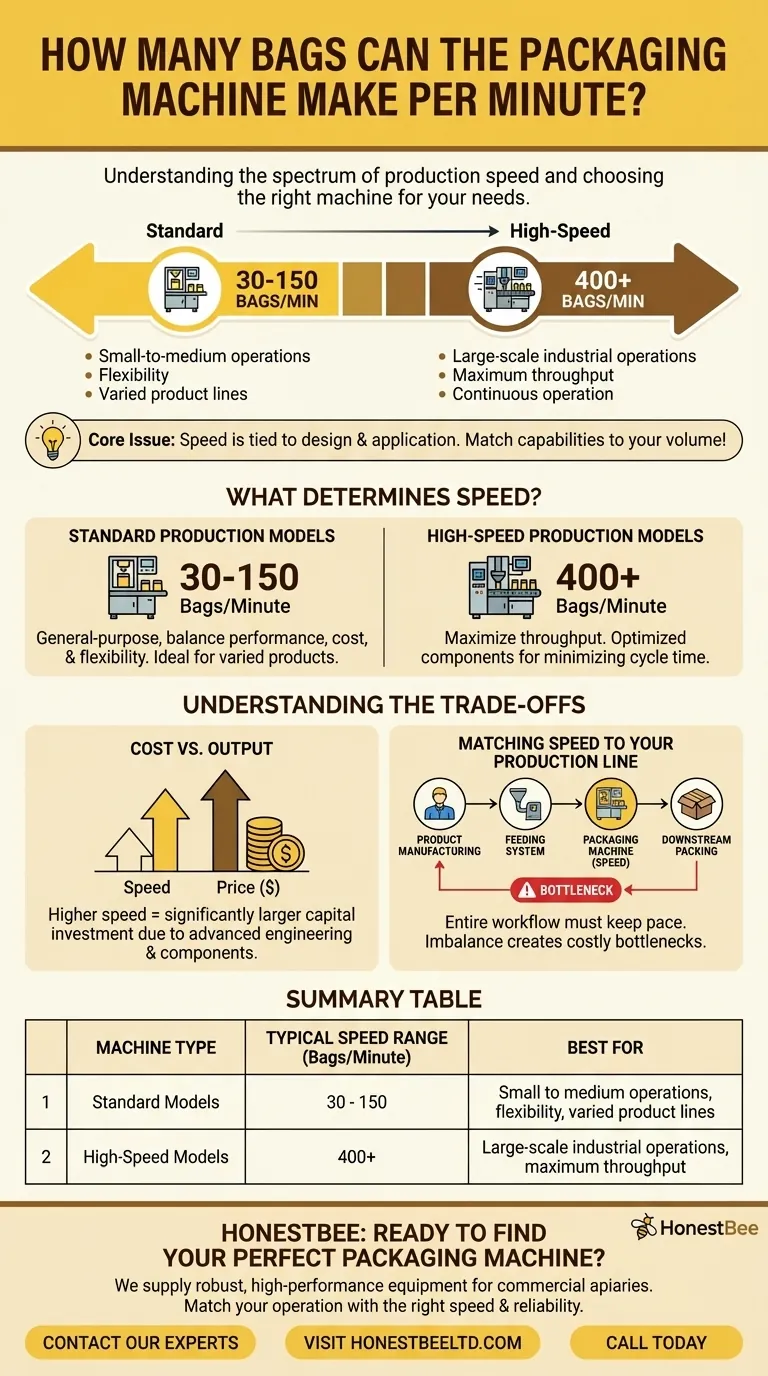

The production speed of a packaging machine is not a single figure, but rather a wide spectrum. Standard or smaller machines typically produce between 30 and 150 bags per minute, while high-speed models are engineered to exceed this, sometimes reaching 400 bags per minute or more.

The core issue is not finding a single speed, but understanding that a machine's output is directly tied to its design and intended application. Choosing the right machine means matching its speed capabilities to your specific production volume and operational scale.

What Determines a Packaging Machine's Speed?

A machine's potential output is governed by its mechanical and electrical design. The primary distinction lies between standard machines built for flexibility and high-speed models engineered for pure throughput.

Standard Production Models

Most general-purpose packaging machines fall into this category. Their speed, typically ranging from 30 to 150 bags per minute, is designed to serve small to medium-sized operations.

This range offers a balance between performance, cost, and operational flexibility, making it suitable for businesses with varied product lines or those that do not require massive, continuous output.

High-Speed Production Models

These machines are built for a singular purpose: maximizing throughput. By achieving speeds of 400 bags per minute or even higher, they cater to large-scale industrial operations where volume is the critical metric.

Everything in their design, from the servo motors to the film transport systems, is optimized to minimize cycle time and run continuously at peak performance.

Understanding the Trade-offs

Selecting a machine based on speed alone can be a critical error. The fastest machine is not always the best solution, as higher speeds introduce significant trade-offs in cost, complexity, and operational requirements.

Cost vs. Output

There is a direct correlation between a machine's speed and its price. A high-speed model represents a significantly larger capital investment than a standard machine.

This higher cost is a function of the advanced engineering, more robust components, and precision controls required to operate reliably at such high velocities.

Matching Speed to Your Production Line

The packaging machine is just one component of a larger production line. A machine capable of 400 bags per minute is only effective if your product manufacturing, feeding, and downstream case-packing systems can keep pace.

An imbalance creates a bottleneck, meaning you have paid for performance you cannot actually use. The entire workflow must be analyzed to justify the investment in a high-speed system.

Making the Right Choice for Your Goal

To select the appropriate machine, you must first define your primary operational objective. Your required output dictates your choice.

- If your primary focus is flexibility or managing a small-to-medium volume: A machine in the 30-150 bags per minute range offers the best balance of cost and capability.

- If your primary focus is maximizing throughput for a high-demand product: Investing in a high-speed model capable of 400+ bags per minute is necessary to meet large-scale production goals.

Ultimately, understanding this spectrum of performance allows you to invest in a solution that directly serves your business needs.

Summary Table:

| Machine Type | Typical Speed Range (Bags/Minute) | Best For |

|---|---|---|

| Standard Models | 30 - 150 | Small to medium operations, flexibility, varied product lines |

| High-Speed Models | 400+ | Large-scale industrial operations, maximum throughput |

Ready to find the perfect packaging machine for your output goals?

At HONESTBEE, we supply robust, high-performance packaging equipment and supplies tailored for commercial apiaries and beekeeping equipment distributors. We help you avoid costly bottlenecks by matching your operation with a machine that delivers the right speed and reliability.

Contact our experts today to discuss your production needs and get a solution that scales with your business.

Visual Guide

Related Products

- Professional Durable Customizable Blister Packing Machine

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Automatic In-Line Flat Surface Labeling Machine

- Semi Automatic Electric Bottle Capping Machine

People Also Ask

- How do I choose a packing machine? A Guide to Strategic Investment and Seamless Integration

- What are the benefits of using packaging machines? Boost Efficiency, Cut Costs & Elevate Your Brand

- What is the function of a sealing machine? Protect Product Integrity with Airtight Heat & Pressure Seals

- What is the working principle of bottle packing machine? Achieve Efficient, Automated Filling

- What is the importance of versatility and adaptability in a honey packaging machine? Future-Proof Your Production