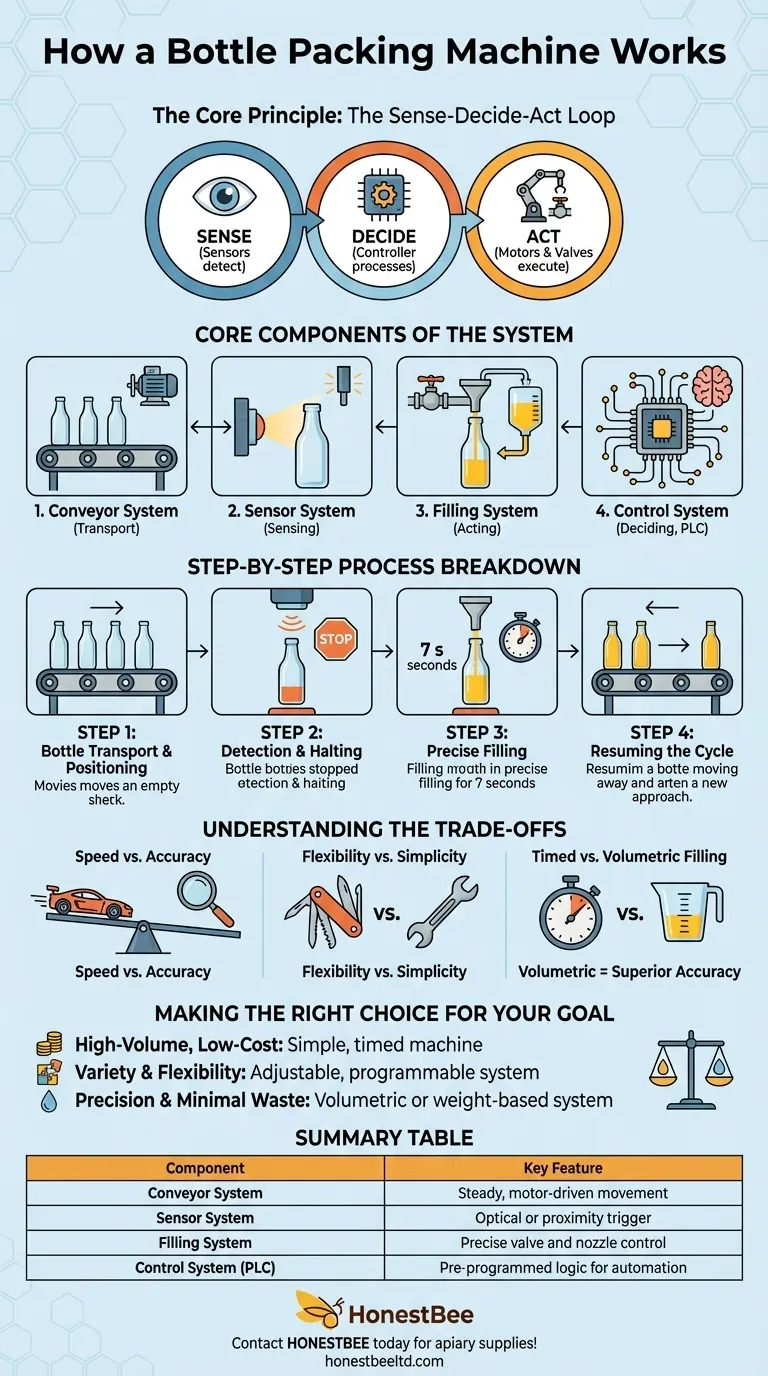

At its core, a bottle packing machine operates on a simple, automated sequence: a conveyor moves a bottle into position, a sensor detects it, the conveyor stops, a valve dispenses a precise amount of product, and the conveyor then moves the next bottle into place. This cycle repeats continuously to achieve efficient, automated filling.

The fundamental working principle is not just a mechanical process, but a control loop. The machine constantly uses sensors to Sense the state of the line, a controller to Decide the next action, and motors or valves to Act on that decision.

The Core Components of the System

To understand the principle, we must first understand the key players involved in this automated process. Each component has a distinct and critical role in the machine's operation.

The Conveyor System (Transport)

This is the backbone of the machine. Driven by a motor, the conveyor belt provides the constant, steady movement of bottles from one station to the next.

The Sensor System (Sensing)

Sensors are the eyes of the operation. An optical or proximity sensor is placed at the filling station to detect when a bottle is correctly positioned underneath the nozzle. This detection is the trigger for the entire filling sequence.

The Filling System (Acting)

This system consists of a product reservoir, a valve, and a nozzle. When triggered by the control system, the valve opens, allowing the product to flow through the nozzle and into the bottle. The precision of this valve is critical for consistent filling.

The Control System (Deciding)

This is the brain of the machine, often a Programmable Logic Controller (PLC). It receives signals from the sensor and executes a pre-programmed sequence of commands, such as "stop the motor" or "open the valve for 7 seconds."

A Step-by-Step Breakdown of the Process

The interaction between the core components creates a reliable and repeatable cycle. The entire operation can be broken down into a few distinct steps.

Step 1: Bottle Transport and Positioning

The cycle begins with the motor running the conveyor belt. Empty bottles are fed onto the line and travel towards the filling station.

Step 2: Detection and Halting

As a bottle arrives at the filling station, it passes in front of the sensor. The sensor sends a signal to the control system, which immediately commands the conveyor motor to stop. This ensures the bottle is perfectly aligned under the filling nozzle.

Step 3: Precise Filling

With the bottle stationary, the control system commands the filling valve to open. It remains open for a predetermined amount of time (e.g., 7 seconds) to dispense a specific volume of product.

Step 4: Resuming the Cycle

Once the timer expires, the control system closes the valve and restarts the conveyor motor. The filled bottle moves on, and the next empty bottle is brought into position, allowing the cycle to repeat seamlessly.

Understanding the Trade-offs

While the principle is straightforward, the design and configuration of a bottle packing machine involve critical trade-offs that impact its performance and suitability for a given task.

Speed vs. Accuracy

Increasing the conveyor speed and shortening the fill time can boost output, but it may come at the cost of accuracy. Faster filling can cause splashing or foaming, and slight variations in timing can lead to inconsistent fill levels.

Flexibility vs. Simplicity

A machine designed for a single bottle size and shape is simple and highly efficient. However, a machine capable of handling various bottle sizes is more flexible but requires more complex components, such as adjustable guide rails and changeover parts, increasing cost and setup time.

Timed Filling vs. Volumetric Filling

The reference example uses a timed fill, which is simple and cost-effective. However, it can be imprecise if the product's flow rate or pressure changes. More advanced systems use volumetric or weight-based filling for superior accuracy, as they measure the actual amount of product dispensed rather than relying on time.

Making the Right Choice for Your Goal

Selecting or designing a packing system requires aligning its principles with your primary operational objective.

- If your primary focus is high-volume, low-cost production: A simple, dedicated machine with timed filling is the most efficient solution.

- If your primary focus is handling a variety of products or bottle sizes: Prioritize a flexible system with easy-to-adjust components and programmable controls.

- If your primary focus is precision and minimizing product waste: A machine using volumetric or weight-based filling sensors is superior to a simple timed system.

Understanding this core loop of sensing, deciding, and acting is the key to evaluating and optimizing any automated packaging system.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Conveyor System | Transports bottles | Steady, motor-driven movement |

| Sensor System | Detects bottle position | Optical or proximity trigger |

| Filling System | Dispenses product | Precise valve and nozzle control |

| Control System (PLC) | Manages the sequence | Pre-programmed logic for automation |

Ready to optimize your packaging line? HONESTBEE supplies robust, high-performance beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors. Whether you need reliable components for a custom machine or efficient systems for high-volume honey filling, our wholesale-focused operations deliver the durability and precision your business depends on. Contact HONESTBEE today to discuss your specific needs and enhance your operational efficiency!

Visual Guide

Related Products

- Semi Automatic Electric Bottle Capping Machine

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Semi Automatic Round Bottle Labeling Machine

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

People Also Ask

- What are the advantages of using automated labeling and sealing equipment for honey export? Boost Quality & Compliance

- What is the purpose of bottle capping equipment and what types are available? Professional Sealing Solutions

- What equipment is used for bottling honey cleanly and efficiently? Professional Filling Solutions for Every Scale

- How do modern honey packaging and sealing equipment enhance the commercial value of honey products? Boost Your ROI Today

- What is the purpose of a bottle capping machine? Boost Efficiency and Ensure Product Integrity