To properly prepare wax for dipping foundation, it must be heated to a consistent 190°F in a double-vat system. This process involves melting the wax overnight, allowing it to remain insulated so that impurities can settle to the bottom. The final step is to ensure the wax is fully liquid for 2-3 hours before dipping begins.

The core principle behind preparing wax is not just liquefaction, but purification. The goal is to use a controlled, extended heating and settling process to create a supply of consistently hot, clean wax, which is critical for producing high-quality foundation.

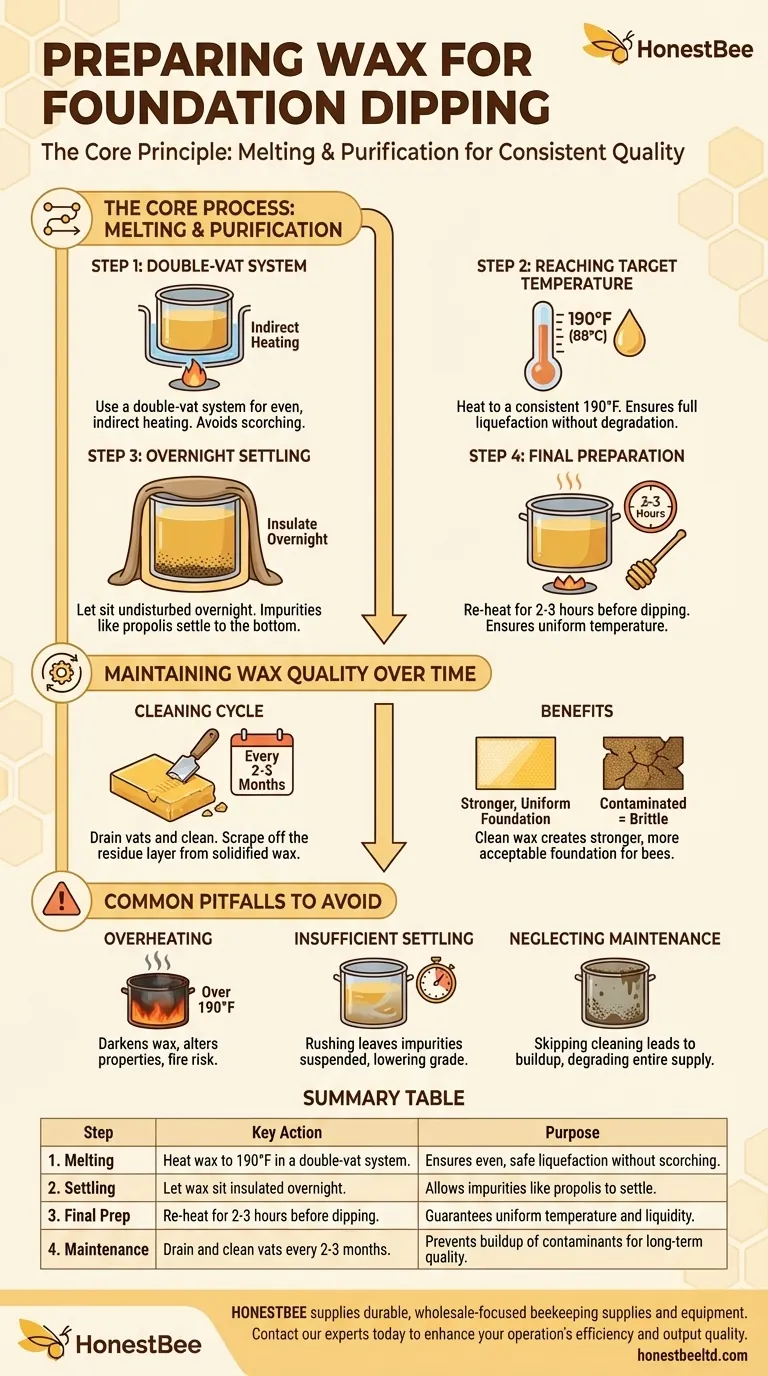

The Core Process: Melting and Purification

Properly preparing your wax is a multi-step process focused on achieving the right temperature and removing contaminants. Each stage plays a vital role in the quality of the final foundation sheets.

The Double-Vat System

The process begins by using double-vats, which function like a water-jacketed boiler. This design ensures the wax is heated indirectly and evenly, preventing scorching or hot spots that can damage the wax.

Reaching the Target Temperature

The wax is heated to 190°F (approximately 88°C). This specific temperature is high enough to ensure the wax is completely liquid but low enough to avoid discoloration or degradation. Maintaining this temperature provides a continuous, stable supply for the dipping process.

The Overnight Settling Period

The vats are typically heated and then insulated to retain their heat overnight. This extended period of static heat is crucial for purification. As the wax sits undisturbed, heavier impurities like propolis and other hive debris slowly settle to the bottom of the vat.

Final Preparation Before Dipping

About two to three hours before you plan to begin dipping, the vats should be turned back on. This ensures that the entire volume of wax is uniformly liquid and has returned to the target temperature of 190°F.

Maintaining Wax Quality Over Time

Preparing the wax isn't a one-time event. Long-term quality depends on a consistent maintenance schedule to prevent the accumulation of impurities that can compromise the foundation.

The Importance of Purity

Clean wax produces stronger, more uniform foundation sheets that bees are more likely to accept and build upon. Contaminated wax can result in brittle foundation or introduce unwanted elements into the hive.

The Periodic Cleaning Cycle

Every two to three months, the vats should be completely drained. The wax is poured into pans and allowed to solidify.

Once the wax is solid, the block can be removed and the dark, residue-laden layer at the bottom can be scraped off. This simple act physically removes the settled impurities from your wax supply.

Common Pitfalls to Avoid

Mistakes in the wax preparation process can significantly impact your results. Understanding these common errors is key to maintaining a high standard of quality.

Overheating the Wax

Exceeding the target temperature can darken the wax and alter its natural chemical properties. In extreme cases, it poses a fire risk. A double-vat system helps mitigate this, but careful temperature monitoring is still essential.

Insufficient Settling Time

Rushing the overnight settling process is a common mistake. If the wax doesn't have enough time to sit undisturbed, impurities will remain suspended, leading to a lower-grade foundation.

Neglecting Vat Maintenance

Skipping the periodic cleaning cycle allows impurities to build up. Over time, this will degrade the quality of your entire wax supply, making it progressively harder to produce clean foundation sheets.

Key Steps for a Successful Wax Preparation

Your approach should align with your primary operational goals. Use these guidelines to focus your efforts.

- If your primary focus is Purity and Quality: Prioritize the overnight settling period and adhere strictly to the 2-3 month cleaning and scraping schedule.

- If your primary focus is Consistency and Efficiency: Master the control of your double-vat system to maintain a constant 190°F and always pre-heat for 2-3 hours before starting work.

Ultimately, meticulous wax preparation is the foundation for creating strong, healthy honeybee colonies.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Melting | Heat wax to 190°F in a double-vat system. | Ensures even, safe liquefaction without scorching. |

| 2. Settling | Let wax sit insulated overnight. | Allows impurities like propolis to settle to the bottom. |

| 3. Final Prep | Re-heat for 2-3 hours before dipping. | Guarantees uniform temperature and liquidity. |

| 4. Maintenance | Drain and clean vats every 2-3 months. | Prevents buildup of contaminants for long-term quality. |

Produce stronger, more uniform foundation with a reliable wax supply.

For commercial apiaries and distributors, consistent, high-quality foundation starts with proper wax preparation and the right equipment. HONESTBEE supplies the durable, wholesale-focused beekeeping supplies and equipment you need to optimize your foundation production, from double-vat melters to temperature control tools.

Contact our experts today to discuss how our solutions can enhance your operation's efficiency and output quality.

Visual Guide

Related Products

- Professional Honey Uncapping Roller for Efficient Harvesting

- Stainless Steel J Hook Hive Tool for Beekeeping

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- Professional Stainless Steel Pry-Bar Hive Tool

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- What is the function of pre-installed honeycomb wax sheets in experimental bee colonies? Achieve Research Consistency

- What is the necessity of integrating wax foundation into artificial honeybee labs? Optimize Bee Health & Data Accuracy

- How do bees use wax sheets in the hive? A Guide to Foundation for Better Beekeeping

- Why is the periodic replacement of comb foundation wax necessary? Ensure Hive Health and Honey Purity

- How does high-purity beeswax foundation contribute to the production efficiency of a commercial honey operation?

- What is the primary objective of embossing top bars or foundations? Master Hive Structure and Efficiency

- What is the primary purpose of using worker-sized wax foundations in Varroa mite resistance screening? Enhance Research

- What are the potential issues if the wax or dipping process is not properly managed? Avoid Cracks, Ripples, and Delamination