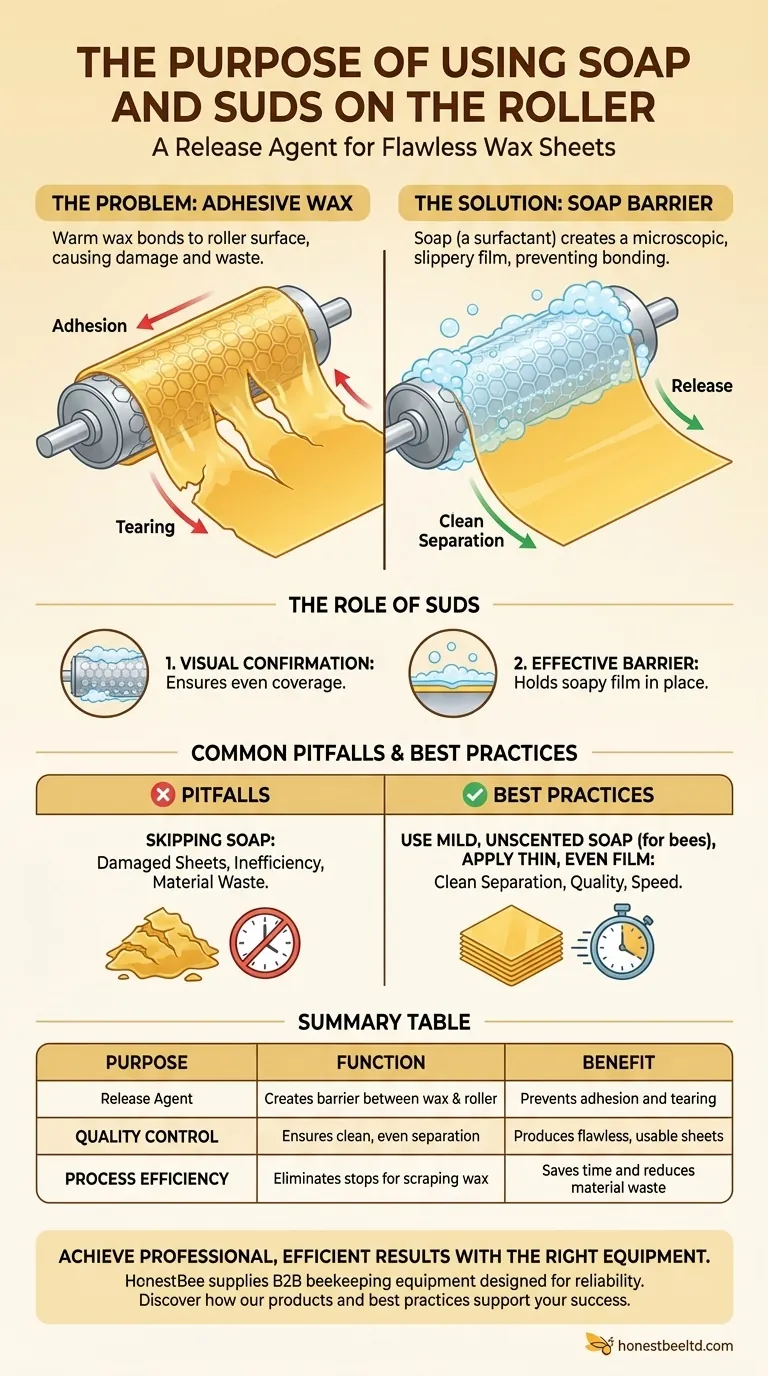

The primary purpose of using soap and suds on a roller is to act as a release agent. This thin, soapy film creates a barrier that prevents the warm, sticky wax from adhering to the roller's surface, ensuring that the finished wax sheets can be removed cleanly and without tearing.

At its core, this practice is not just about lubrication; it is a critical step in quality control. Applying soap and suds is the simplest and most effective way to guarantee a clean separation between your material and your equipment.

The Problem: Why Wax Sticks

Wax, especially when warmed to a pliable state for rolling, is naturally adhesive. Understanding this property is key to understanding why a release agent is necessary for a smooth process.

The Adhesive Nature of Wax

When you roll wax, you are applying pressure that forces it into the fine details of the roller's surface. The warm wax molecules have a tendency to bond with the metal or plastic of the roller, creating a strong adhesive connection.

The Impact of Surface Tension

Without a barrier, the wax will stick unevenly across the roller. As the roller turns, this adhesion will pull, stretch, and ultimately tear the delicate sheet you are trying to form.

How Soap Solves the Adhesion Problem

Soap is a surfactant, meaning it has a unique molecular structure that reduces surface tension between liquids and solids. This property makes it an ideal release agent in this context.

Creating a Microscopic Barrier

When you apply soap and water to the roller, you create an ultra-thin, slippery film. This film sits between the roller's surface and the wax, physically preventing the wax from making direct contact and bonding with the roller.

The Role of Suds

The suds, or lather, serve two practical purposes. First, they are a visual confirmation that the soap solution is present and evenly distributed across the entire surface of the roller. Second, the suds help hold the soapy water in place, ensuring the barrier remains effective during rolling.

Common Pitfalls and Best Practices

Failing to use a release agent is the most common mistake, but the way you use it also matters. The goal is to create a flawless sheet, and that requires proper technique.

Consequence 1: Damaged or Unusable Sheets

The most immediate consequence of skipping the soap is product failure. The wax will adhere firmly to the roller, resulting in torn, stretched, and completely unusable sheets.

Consequence 2: Process Inefficiency

If wax sticks, you must stop the process to scrape it off the roller. This is time-consuming, frustrating, and leads to significant material waste. A continuous, efficient workflow is impossible without a good release agent.

Best Practice: Use a Mild, Unscented Soap

For applications like beekeeping, where the wax foundation will be introduced to a hive, it is critical to avoid contamination. Use a mild, natural, and unscented soap to prevent introducing foreign chemicals or smells that could harm or repel the bees.

Best Practice: Apply a Thin, Even Film

The goal is a slippery surface, not a soaking wet one. Too much water can cool the wax prematurely or create imperfections in the sheet. Apply a thin, consistent layer of suds just before the wax makes contact with the roller.

Making the Right Choice for Your Goal

Properly using a release agent is fundamental to the success of your project. Your primary goal will determine how you view this essential step.

- If your primary focus is high-quality output: Treat the application of soap as a non-negotiable step for achieving perfectly formed, defect-free wax sheets every time.

- If your primary focus is efficiency and speed: View the soap as a critical time-saving tool that prevents frustrating stops, difficult cleanup, and wasted material.

This simple technique is the key to transforming a difficult task into a smooth and professional process.

Summary Table:

| Purpose | Function | Benefit |

|---|---|---|

| Release Agent | Creates a barrier between wax and roller | Prevents adhesion and tearing |

| Quality Control | Ensures clean, even separation | Produces flawless, usable sheets |

| Process Efficiency | Eliminates stops for scraping wax | Saves time and reduces material waste |

Achieve professional, efficient results with the right equipment and supplies.

Struggling with wax sticking to your rollers? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, wholesale beekeeping supplies designed for reliability and efficiency. Our equipment, combined with best practices like using a proper release agent, helps you produce perfect wax sheets every time, minimizing waste and maximizing your productivity.

Contact HONESTBEE today to discuss your wholesale supply needs and discover how our products can support your success.

Visual Guide

Related Products

- Professional Honey Uncapping Roller for Efficient Harvesting

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What is the purpose of the beeswax flatting and embossing machine? Boost Hive Efficiency & Honey Production

- What is the role of a Beeswax Foundation Machine? Optimize Hive Efficiency & Boost Honey Production

- What role does a comb foundation mill play in manufacturing? Mastering Hive Standardization and Apiary Efficiency

- How do specialized beeswax processing machines maximize the value of beekeeping by-products? Boost Your Apiary's ROI

- What is the function of a manual wax roller? Master Hive Foundation Production with Precision

- How does a Wax Foundation Embosser contribute to bee colony efficiency? Boost Apiculture Productivity and Hive Health

- What is the function of a manual tablet press machine in beekeeping? Create Pure Beeswax Foundation for Your Hives

- What role does standardized comb foundation equipment play in the production of high-quality bee bread?