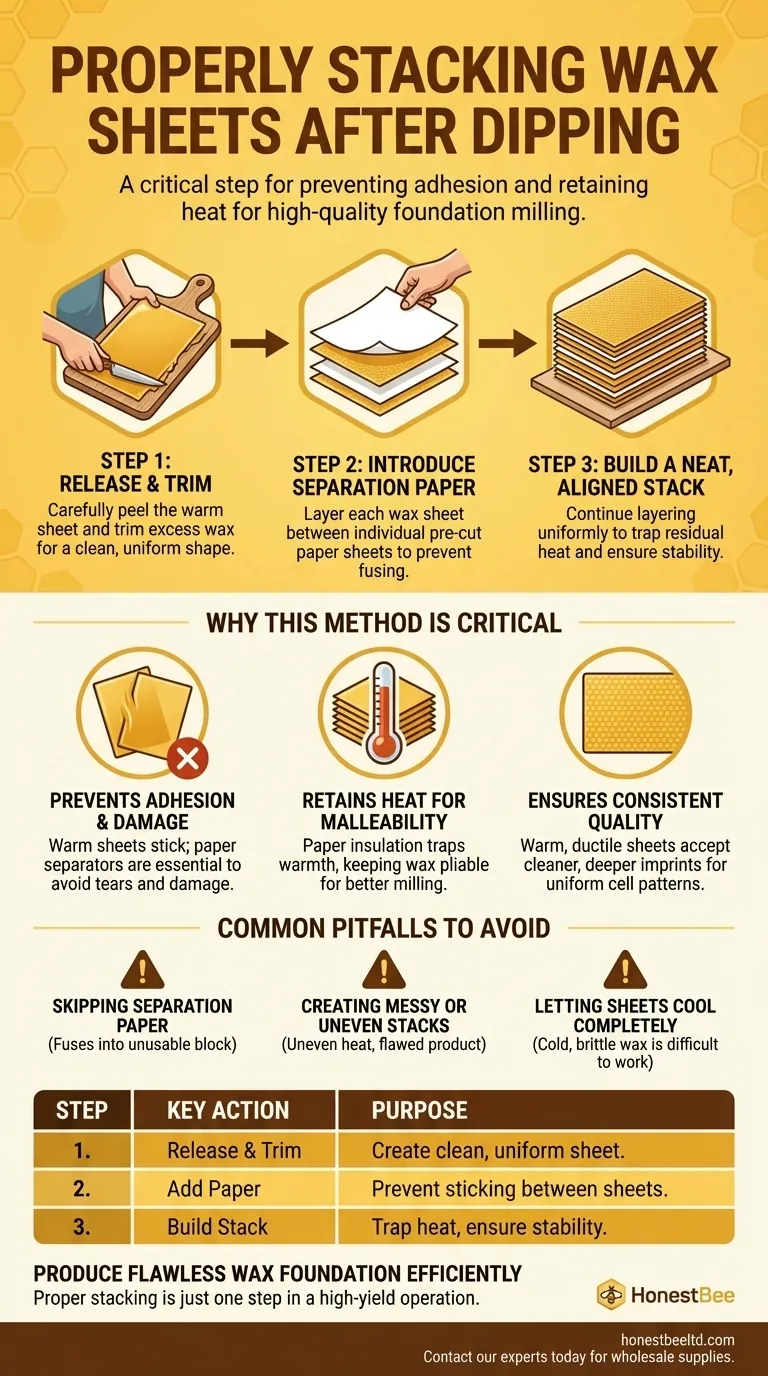

To properly stack wax sheets, you must layer them between sheets of pre-cut paper on a flat board or plate. After peeling the wax from the dipping board and trimming the edges, this layering technique prevents the warm, pliable sheets from sticking together and helps retain heat. This retained warmth is essential for making the subsequent milling or embossing process smoother and more effective.

The core principle of stacking wax sheets is not just about storage, but about preparation. Using separation paper and creating neat stacks is a critical step that prevents damage while preserving the warmth and ductility needed for high-quality foundation.

The Core Stacking Procedure

Properly stacking your freshly dipped wax sheets is a straightforward but vital process. Each step is designed to protect the integrity of the sheet and prepare it for the final stages of production.

Step 1: Release and Trim

Before stacking, carefully peel the new wax sheet off the dipping board. Once removed, use a knife to trim the excess wax from around the sides for a clean, uniform shape.

Step 2: Introduce Separation Paper

Place a sheet of pre-cut paper onto your stacking board or plate. Lay your freshly trimmed wax sheet flat on top of this paper.

Immediately place another sheet of paper over the wax. This paper is the key to preventing the warm, tacky wax sheets from fusing together.

Step 3: Build a Neat, Aligned Stack

Continue this process, layering each new wax sheet between individual sheets of paper. It is crucial to stack them as neatly and uniformly as possible.

An aligned stack is more stable and efficient at trapping the residual heat from the dipping process.

Why This Method is Critical

The way you stack your sheets directly impacts the quality of your final wax foundation. Skipping these steps can lead to wasted material and a frustrating milling experience.

Preventing Adhesion and Damage

Warm wax sheets are naturally adhesive. Without paper separators, they will stick firmly to one another, making them impossible to separate without causing tears and damage.

Retaining Heat for Malleability

The process works best when the wax is warm and pliable. Neatly stacking the sheets with paper insulation traps a significant amount of warmth, keeping the wax in an ideal state for milling or embossing. Cold, brittle wax is much more difficult to work with.

Ensuring Consistent Quality

A warm and ductile wax sheet accepts the imprint from an embossing mill more cleanly and deeply. This ensures a consistent, high-quality cell pattern across your entire batch of foundation.

Common Pitfalls to Avoid

While the process is simple, a few common mistakes can undermine your efforts and lead to poor results. Being aware of them is key to a smooth workflow.

Skipping the Separation Paper

This is the most critical error. Failing to use paper between each layer will result in a single, unusable block of fused wax sheets, forcing you to remelt and restart the entire process.

Creating Messy or Uneven Stacks

Haphazardly piling the sheets reduces their stability and allows heat to escape unevenly. This can create cool spots in the wax, leading to inconsistent ductility and a flawed final product.

Letting Sheets Cool Completely

Do not dip all your sheets and leave them sitting out individually before stacking. Stack them immediately after trimming to capture as much of the heat from the dipping process as possible.

Best Practices for Your Workflow

To integrate this into your process effectively, consider your primary goal.

- If your primary focus is speed and efficiency: Pre-cut all your separation paper and have your stacking board ready before you even begin dipping the first sheet.

- If your primary focus is maximum quality: Pay close attention to creating a perfectly aligned stack to ensure heat is retained as evenly as possible for a superior embossing result.

Ultimately, proper stacking is the essential bridge between dipping and milling that ensures your final foundation is both durable and well-formed.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Release & Trim | Peel sheet from board and trim edges. | Create a clean, uniform sheet for stacking. |

| 2. Add Paper | Place a wax sheet between two pre-cut paper sheets. | Prevent warm, tacky sheets from sticking together. |

| 3. Build Stack | Continue layering, keeping the stack neat and aligned. | Trap heat for malleability and ensure stability. |

Produce flawless wax foundation efficiently. Proper stacking is just one step in a high-yield beekeeping operation. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed for quality foundation production. Contact our experts today to discuss your equipment needs and boost your productivity.

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Food Grade Plastic bee Foundation for Bee Frames

People Also Ask

- What is the purpose of sorting honeycombs, cappings, and sefef before rendering? Ensure Pure, High-Grade Beeswax

- What are the benefits of making your own beeswax foundation? Achieve Purity and Biosecurity in Your Apiary

- What should a beekeeper do if they notice a lack of beeswax in a hive? Guide to Hive Repair & Beeswax Sourcing

- What are the three main modern options for bee foundation materials? Choose the Best for Your Apiary

- How long do beeswax sheets last? Extend Their Life Beyond a Year with Proper Care

- When should I replace my bee foundation? A Proactive Guide to Hive Health

- Why is pre-formed wax foundation necessary in beehive frames? Optimize Hive Structure & Honey Yield

- How does crimped wire foundation improve the structure of beeswax foundation? Prevent Sagging & Comb Blowouts