The most direct support available for selecting a honey packaging machine comes from professional sales and customer service teams. These specialists are trained to assist you in planning and choosing the right equipment by analyzing your specific operational needs, production volume, and packaging requirements.

The key to a successful purchase is not just finding support, but knowing the right questions to ask. A trusted advisor's main role is to help you map your specific production goals—like volume, packaging type, and honey viscosity—to the precise capabilities of a machine.

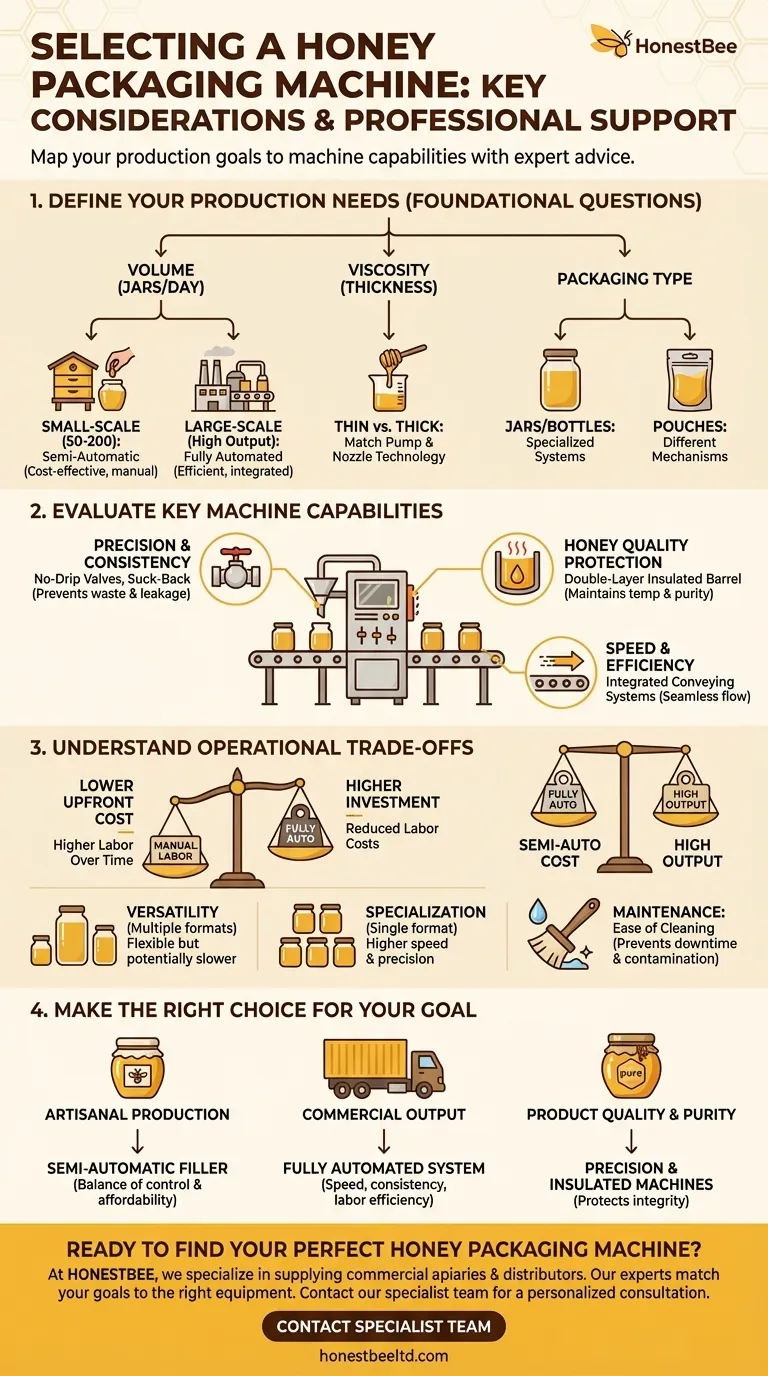

Foundational Questions: Defining Your Production Needs

Before evaluating any machine, a technical advisor will first help you clarify your own operational framework. The right equipment is a direct reflection of your production reality.

Gauging Your Production Volume

The scale of your operation is the primary factor determining your equipment needs. It dictates the level of automation required for efficiency.

Small-scale or artisanal producers may find a semi-automatic machine, capable of filling 50 to 200 jars per day, to be perfectly adequate and cost-effective.

Large-scale commercial operations, however, require fully automated systems. These integrated solutions handle high output with minimal manual intervention.

Understanding Honey's Viscosity

The thickness, or viscosity, of your honey is a critical technical consideration. Different machines are engineered to handle different fluid dynamics to ensure accurate and clean filling.

A professional can help you match your honey's properties to a machine with the appropriate pump and nozzle technology.

Selecting Your Packaging Type

Your choice of container directly influences machine selection. Systems are often specialized for specific packaging formats.

Jar or bottle packing machines are designed to handle various sizes of glass or plastic containers, often incorporating conveying, filling, sealing, and labeling systems.

Other machines may be specifically designed for flexible packaging, such as pouches, which require different filling and sealing mechanisms.

Evaluating Key Machine Capabilities

Once your needs are defined, the focus shifts to the specific features and performance metrics of the equipment.

The Importance of Precision and Consistency

Wasted product and inconsistent fills directly impact your bottom line. Look for features that guarantee accuracy.

Machines for jars often use precise shut-off valves at the nozzle to stop the flow cleanly. Pouch fillers may use a suck-back device to prevent leakage and ensure a clean seal.

Specialized Features for Honey Quality

Honey is a sensitive product. The right machine will have features designed to protect its integrity during the packaging process.

A double-layer insulated barrel, for example, helps maintain a consistent temperature, preserving the honey's concentration and purity without overheating it.

Speed and Overall Efficiency

Machine speed and stable performance are crucial for meeting production targets. An efficient system integrates multiple processes seamlessly.

A complete packaging line often includes a conveying system that moves containers smoothly through each stage, from filling to final labeling.

Understanding the Operational Trade-offs

Every equipment choice involves balancing competing priorities. Understanding these trade-offs is the hallmark of an informed decision.

Cost-Effectiveness vs. Upfront Investment

A semi-automatic machine has a lower initial cost but requires more labor. A fully automatic system is a significant upfront investment that pays off through higher output and reduced labor costs over time.

Versatility vs. Specialization

Some machines offer versatility, capable of handling different container shapes and sizes. However, a machine specialized for a single container type may offer higher speed and precision for that specific format.

Maintenance and Ease of Cleaning

This is a critical, often-overlooked factor. A machine that is difficult to clean can lead to downtime and potential product contamination. Always inquire about the cleaning process and maintenance requirements.

Making the Right Choice for Your Goal

Your optimal choice depends entirely on your primary business objective.

- If your primary focus is small-scale, artisanal production: A semi-automatic filler offers the best balance of control, affordability, and sufficient output.

- If your primary focus is high-volume commercial output: A fully automated system is non-negotiable for achieving the necessary speed, consistency, and labor efficiency.

- If your primary focus is product quality and purity: Prioritize machines with features like insulated barrels and precision no-drip filling mechanisms.

By thoroughly defining your needs first, you can select a machine that serves as a powerful asset for your operation.

Summary Table:

| Key Consideration | Why It Matters | Key Question to Ask |

|---|---|---|

| Production Volume | Determines automation level (semi-auto vs. fully automatic). | What is your target output (jars/day)? |

| Honey Viscosity | Affects pump and nozzle technology for accurate filling. | How thick is your honey? |

| Packaging Type | Machines are specialized for jars, bottles, or pouches. | What container will you use? |

| Key Features | Ensures precision, protects honey quality, and boosts efficiency. | Does it have no-drip valves and insulated barrels? |

Ready to find the perfect honey packaging machine for your commercial apiary or distribution business?

At HONESTBEE, we specialize in supplying beekeeping equipment to commercial apiaries and distributors through wholesale-focused operations. Our experts will analyze your specific production goals to match you with a machine that maximizes your efficiency and protects your product quality.

Contact our specialist team today for a personalized consultation and quote.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- Why is automated honey filling and labeling machinery essential? Scale Your Honey Export to High-End Global Markets

- What is the volumetric filling method? Achieve Precise, Consistent Product Dosing

- How does automated honey filling equipment contribute to the industrial value of honey? Scale Your Premium Honey Brand

- Why are high-precision honey filling machines necessary? Elevate Your Commercial Beekeeping Brand and Safety

- How does automated filling equipment support the enhancement of market value for honey? Scaling Your Brand Value

- What maintenance procedures are required for a honey-filling machine? Essential Tips for Longevity and Efficiency

- How can jamming or blockage of film be resolved in honey stick machines? A Guide to Minimize Downtime

- Why are professional honey-filling machines essential? Scale Your Export Production and Boost Brand Value