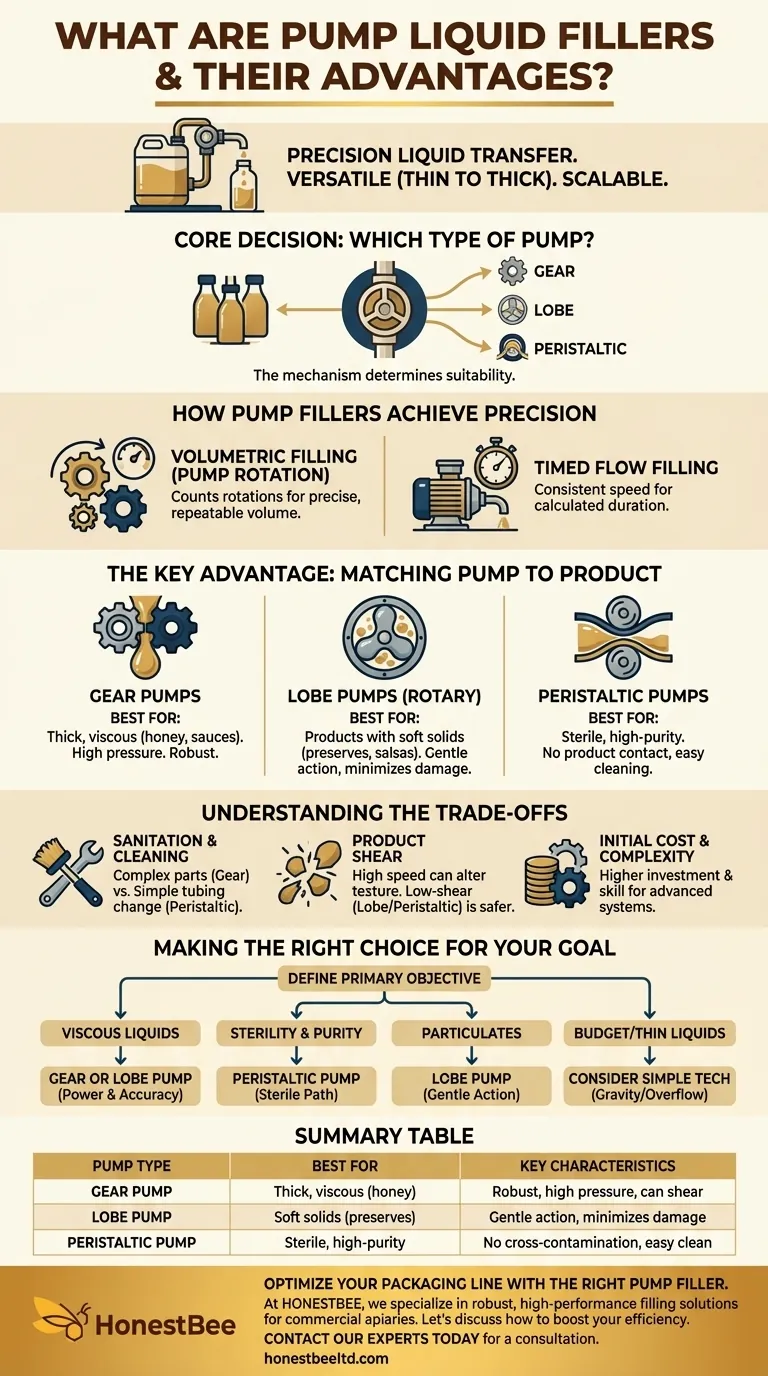

In short, a pump liquid filler is a packaging machine that uses a pump to transfer a precise volume of a liquid product from a bulk source into individual containers. Its primary advantages are its remarkable versatility in handling a wide range of product viscosities—from thin juices to thick honey—and its scalability for growing production demands.

The core decision when considering a pump filler is not whether to use one, but which type of pump to use. The specific pump mechanism (e.g., gear, lobe, or peristaltic) is what determines the filler's suitability for your unique product and operational needs.

How Pump Fillers Achieve Precision

A pump filler operates on a straightforward principle: controlling the amount of product dispensed by controlling the pump's operation. This is typically achieved in one of two ways.

Volumetric Filling via Pump Rotation

For positive displacement pumps like gear or lobe pumps, each rotation moves a precise, repeatable volume of liquid. The machine's control system simply counts the rotations (or partial rotations) of the pump's internal components to deliver the exact target volume into the container.

Timed Flow Filling

A simpler method involves running the pump at a consistent speed for a precisely calculated duration. Assuming a constant product viscosity and pressure, this timed flow results in a highly repeatable fill volume. This method is common across various pump types.

The Key Advantage: Matching the Pump to the Product

The true power of a pump filler lies in its adaptability. By selecting the right pump head for the machine, you can handle an enormous variety of products.

Gear Pumps

Gear pumps use a set of meshing gears to push liquid forward. They are robust and generate strong pressure, making them an excellent choice for thick, viscous products like honey, molasses, or thick sauces.

Lobe Pumps (Rotary Pumps)

Similar to gear pumps, lobe pumps use intermeshing lobes that do not touch. This gentle action makes them ideal for products with soft, suspended solids, such as fruit preserves, salsas, or curries, as it minimizes damage to the particulates.

Peristaltic Pumps

Peristaltic pumps are unique because the product never touches the pump mechanism itself. The liquid is contained within a flexible tube, which is then squeezed by a series of rotating rollers to propel the fluid forward. This makes them the ultimate choice for high-purity, sterile, or aggressive products, as it eliminates cross-contamination and simplifies cleaning.

Understanding the Trade-offs

While highly versatile, pump fillers are not without their specific considerations. Understanding these trade-offs is crucial for making an informed decision.

Sanitation and Cleaning

Pumps with complex internal parts, like gear pumps, can be more challenging and time-consuming to clean and sanitize between product runs compared to simpler filling technologies. Peristaltic pumps excel here, as you often only need to replace the single-use tubing.

Product Shear

High-speed operation of some pump types, particularly gear pumps, can "shear" or break down delicate products, altering their texture or consistency. For shear-sensitive emulsions or products with soft solids, a low-shear pump like a lobe or peristaltic pump is a much safer choice.

Initial Cost and Complexity

Pump fillers, especially those with advanced servo-driven controls, represent a higher initial capital investment compared to entry-level overflow or gravity fillers. Their mechanical complexity also requires a higher level of technical skill for maintenance and operation.

Making the Right Choice for Your Goal

To select the appropriate filling system, you must first define your primary objective.

- If your primary focus is viscous liquids: A gear or lobe pump filler will provide the power and accuracy needed to move thick products efficiently.

- If your primary focus is sterility and purity: A peristaltic pump filler is the industry standard, ensuring your product path is sterile and easy to validate.

- If your primary focus is handling products with particulates: A lobe pump filler is the superior choice, as its gentle action preserves the integrity of your product's ingredients.

- If your primary focus is budget-friendly filling for thin liquids: You may want to investigate simpler technologies like gravity or overflow fillers, as a pump filler might be over-specified for the task.

Choosing the right pump filler is about aligning the machine's capabilities directly with the physical properties of your product.

Summary Table:

| Pump Type | Best For | Key Characteristics |

|---|---|---|

| Gear Pump | Thick, viscous products (honey, sauces) | Robust, high pressure, can cause product shear |

| Lobe Pump | Products with soft solids (preserves, salsas) | Gentle action, minimizes damage to particulates |

| Peristaltic Pump | Sterile, aggressive, or high-purity products | No cross-contamination, easy cleaning (replace tubing) |

Optimize your packaging line with the right pump filler.

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with robust, high-performance filling solutions. Whether you're scaling up honey production or need a gentle system for delicate products, our expertise ensures you get the right equipment for your specific needs.

Let's discuss how a precision pump filler can boost your efficiency and product quality. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

People Also Ask

- What are the main types of honey filling machines? Expert Guide to Choosing the Best Equipment

- What features do honey stick filling machines offer? Automate Production for Perfect Sticks

- What is the primary role of automatic honey filling machines in export-oriented honey processing? Maximize Global Reach

- What are the benefits of utilizing automatic honey-filling machines? Boost Efficiency and Product Safety

- Why must honey harvesting and filling equipment be adapted for specific bee species? Biology Meets Engineering

- How do automated filling machines contribute to honey production? Scale Your Apiary with Precision Packaging

- What role do professional Honey-filling Machines play in the honey value chain? Elevate Your Commercial Retail Standard

- What role do honey filling and packaging machines play in the honey supply chain? Drive Quality and Efficiency