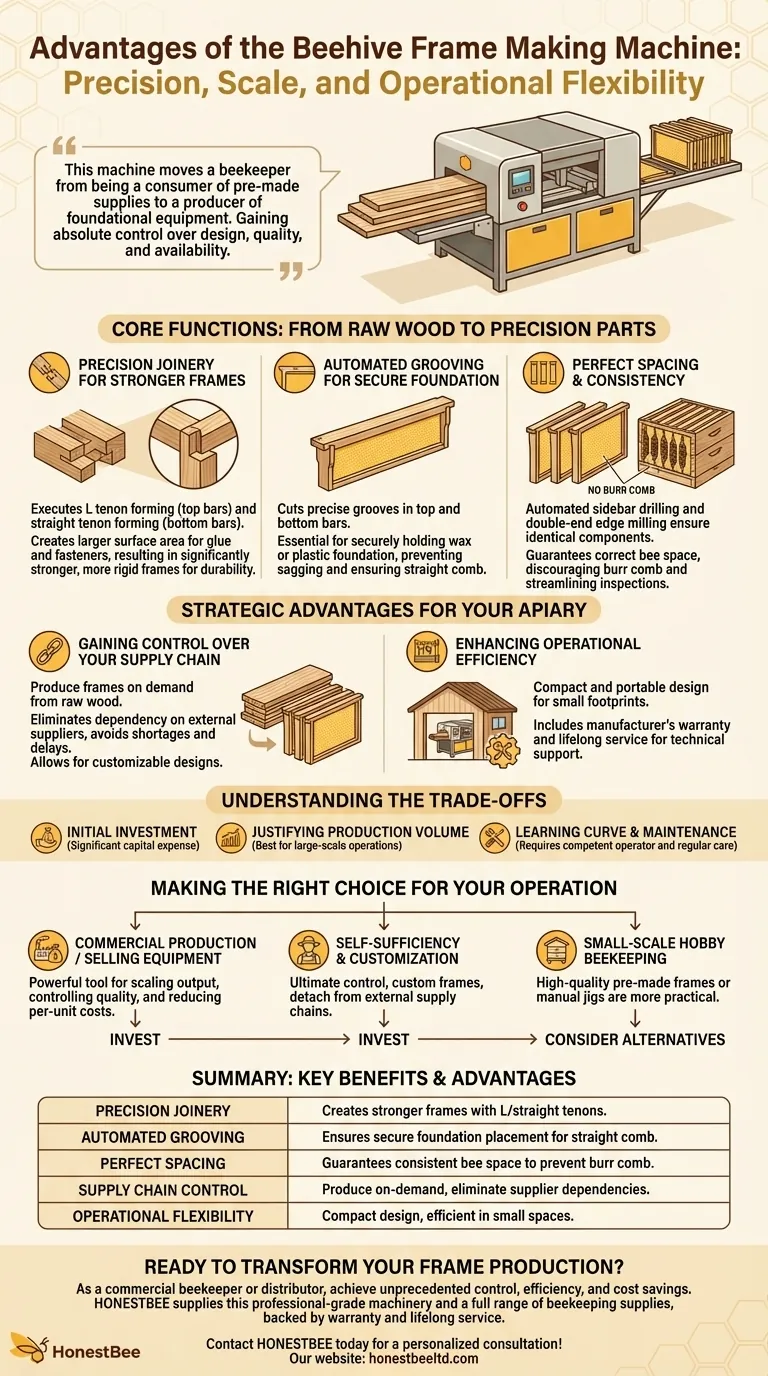

The primary advantages of the Beehive Frame Making Machine are its ability to produce consistent, high-precision components at scale, combined with its operational flexibility. The machine automates complex cuts like tenons and grooves for all frame parts, while its compact design allows for easy transport and storage. This gives the beekeeper direct control over their frame supply chain, from raw material to finished product.

This machine moves a beekeeper from being a consumer of pre-made supplies to a producer of foundational equipment. The core advantage is not just making frames, but gaining absolute control over their design, quality, and availability.

The Core Functions: From Raw Wood to Precision Parts

A common misconception is that this machine simply assembles frames. Its real value lies in its ability to accurately mill and shape each individual piece of the frame from standard lumber.

Precision Joinery for Stronger Frames

The machine creates multiple forms of joinery that are far superior to the simple butt joints found on many mass-produced frames. It executes L tenon forming for top bars and straight tenon forming for bottom bars.

These interlocking joints create a much larger surface area for glue and fasteners, resulting in a significantly stronger and more rigid frame. This durability is critical for withstanding the stress of honey extraction and repeated hive inspections.

Automated Grooving for Secure Foundation

The machine cuts precise grooves into the top and bottom bars. This feature is essential for securely holding wax or plastic foundation in place.

Properly seated foundation prevents sagging and ensures bees build straight, manageable comb, which is fundamental for effective hive management and honey harvesting.

Perfect Spacing and Consistency

By automating sidebar drilling and double-end edge milling, the machine ensures every component is identical. This uniformity is not just for aesthetics; it guarantees correct bee space throughout the hive.

Consistent spacing discourages the bees from building unwanted burr comb between frames, making inspections cleaner, faster, and less disruptive to the colony.

The Strategic Advantages for Your Apiary

Beyond the technical functions, investing in this machine offers significant operational and strategic benefits that can redefine how you manage your apiary.

Gaining Control Over Your Supply Chain

Relying on external suppliers for frames can lead to stock shortages, shipping delays, and fluctuating costs. This machine puts you in complete control.

You can produce frames on demand, using your preferred type of wood. This also unlocks the ability to create customizable designs, adjusting dimensions to suit non-standard hives or specific management techniques.

Enhancing Operational Efficiency

The machine's compact and portable nature means you don't need a large, dedicated workshop. It can be set up in a garage or shed, allowing for efficient production in a small footprint.

Furthermore, the manufacturer's provided warranty and lifelong service offer a layer of security, ensuring you have access to technical support and assistance to maintain productivity.

Understanding the Trade-offs

No technical solution is without its considerations. An objective assessment requires acknowledging the potential challenges alongside the benefits.

The Initial Investment

Specialized machinery represents a significant upfront capital expense compared to buying pre-made frames or using manual jigs. The return on this investment is measured in volume and long-term cost savings on components.

Justifying Production Volume

This machine is designed for production. For a beekeeper with only a handful of hives, the cost and complexity may be difficult to justify. Its value becomes apparent for operators managing dozens or hundreds of colonies, or for those planning to sell frames to other beekeepers.

The Learning Curve and Maintenance

While automated, the machine requires a competent operator who understands wood, tooling, and safety procedures. There will be a learning curve to achieve optimal speed and quality. Regular maintenance, such as blade sharpening and calibration, will also be necessary to ensure continued precision.

Making the Right Choice for Your Operation

The decision to invest in a Beehive Frame Making Machine depends entirely on the scale and goals of your beekeeping.

- If your primary focus is commercial production or selling equipment: This machine is a powerful tool for scaling output, controlling quality, and reducing per-unit costs.

- If your primary focus is self-sufficiency and customization: The machine provides ultimate control over your equipment, allowing you to create custom frames and detach from external supply chains.

- If your primary focus is small-scale hobby beekeeping: Buying high-quality pre-made frames or using simpler manual jigs is likely the more practical and cost-effective approach.

Ultimately, this machine empowers the serious beekeeper to take ownership of the most fundamental component of the modern hive.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precision Joinery | Creates stronger frames with L tenons and straight tenons for superior durability. |

| Automated Grooving | Ensures secure foundation placement for straight comb and easier hive management. |

| Perfect Spacing | Guarantees consistent bee space to prevent burr comb and streamline inspections. |

| Supply Chain Control | Produce frames on-demand from raw wood, eliminating external supplier dependencies. |

| Operational Flexibility | Compact, portable design allows for efficient production in small spaces. |

Ready to Transform Your Frame Production?

As a commercial beekeeper or equipment distributor, you understand the critical importance of reliable, high-quality hive components. The Beehive Frame Making Machine is the key to achieving unprecedented control, efficiency, and cost savings in your operation.

HONESTBEE supplies this professional-grade machinery and a full range of beekeeping supplies to commercial apiaries and distributors. We provide the tools for you to become a producer, not just a consumer. Our expertise ensures you get the right equipment backed by warranty and lifelong service.

Take the next step in scaling your business and securing your supply chain. Let's discuss how this machine can become the cornerstone of your operation.

Contact HONESTBEE today for a personalized consultation!

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

People Also Ask

- What role does standardized wooden beehive manufacturing machinery play? Scale Your Apiary with Industrial Precision

- What reliability and support are offered with the Beehive Frame Making Machine? Secure Your Production Investment

- Why is modern hive construction a highly sought-after skill? Master the Art of Cost-Effective Apiary Expansion

- What is the purpose of a small desktop bee frame forming machine? Automate Frame Assembly for Beekeepers

- How does a bee frame making machine work? A Guide to Automated Metal Frame Production