At its core, a bee frame making machine automates the high-speed production of frame components, specifically the sidebars, from strips of metal. The machine functions like a miniature assembly line, systematically feeding, shaping, and cutting metal to produce consistent parts far faster than any manual process.

The central purpose of this machine is to replace the labor-intensive task of building wooden frames with an industrial process. It trades the tradition of wood for the speed and durability of automated metal fabrication, a choice geared entirely towards large-scale efficiency.

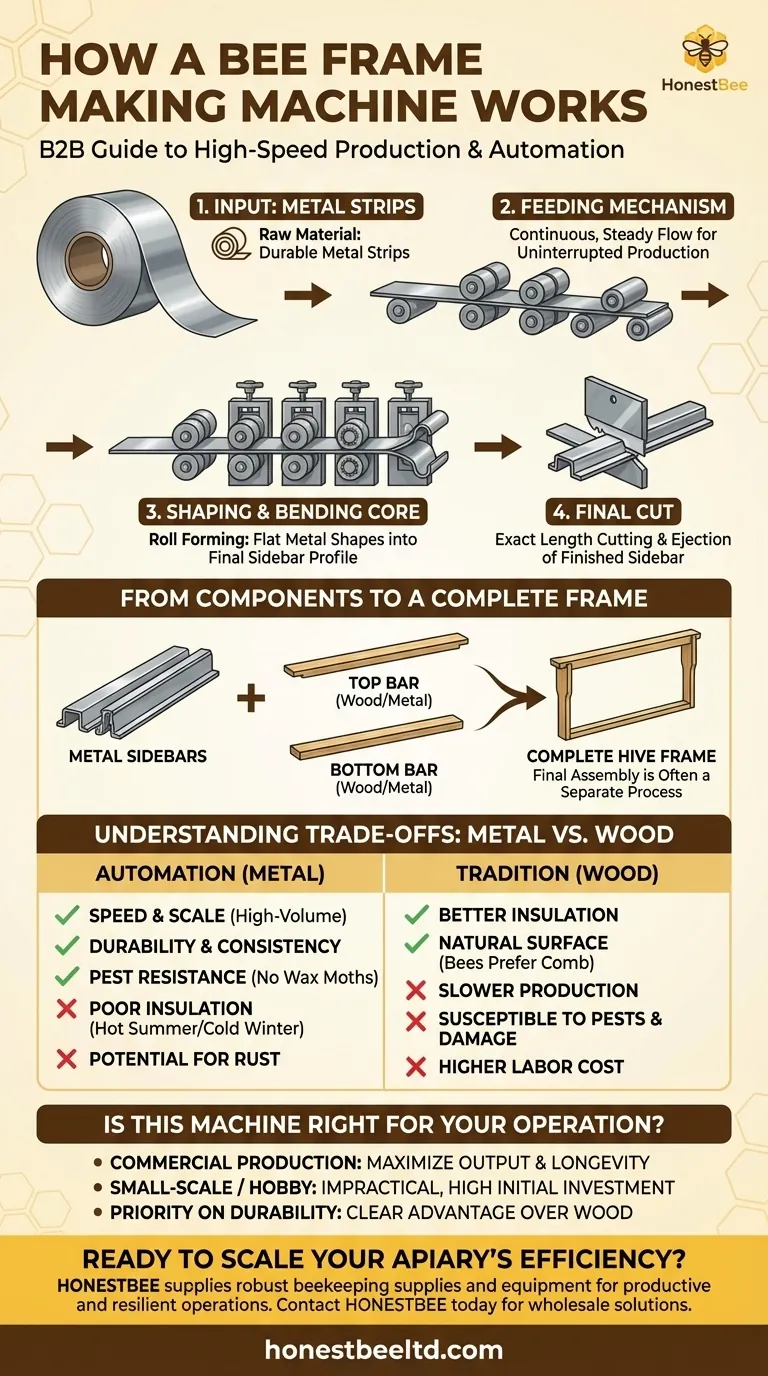

Deconstructing the Automated Process

To understand the machine, it's best to view it as a sequence of distinct mechanical stages. Each stage performs a specific action to transform a simple metal strip into a complex frame component.

The Input: Metal Strips

The entire process begins with a roll of flat metal strip. This material is the raw ingredient, chosen for its ability to be bent and shaped without breaking while offering long-term durability.

The Feeding Mechanism

The machine automatically pulls the metal strip from the roll into the main processing area. This is a crucial first step that ensures a continuous and steady flow of material for uninterrupted production.

The Shaping and Bending Core

This is the heart of the machine. The metal strip passes through a series of customized rollers and bending dies. Each successive roller makes a small, precise bend, gradually forming the flat strip into the final, three-dimensional profile of a frame's sidebar. This industrial technique is known as roll forming.

The Final Cut

Once the metal strip has been fully shaped, a cutting mechanism slices it to the exact length required for a single sidebar. The finished part is then ejected, and the machine immediately begins feeding and shaping the next section.

From Components to a Complete Frame

The machine does not produce a fully assembled frame. It mass-produces one of the most time-consuming components, which must then be integrated with other parts.

Assembling the Final Product

The metal sidebars created by the machine are then typically assembled with a top bar and a bottom bar, which may be made of wood or metal. This final assembly is often still a manual or semi-automated process.

Why Use Metal?

The choice of metal is deliberate. Metal frames are highly durable and resistant to pests like wax moths, which can destroy wooden frames. This manufacturing method allows for the rapid production of thousands of identical, long-lasting components, drastically reducing long-term replacement costs and labor.

Understanding the Trade-offs: Metal vs. Wood

Automating frame production with metal introduces a significant shift away from traditional wooden frames. Understanding the pros and cons is essential.

The Case for Automation (Metal)

The primary advantage is speed and scale. For a commercial beekeeping operation, the ability to produce thousands of frames quickly at a low per-unit labor cost is a massive operational advantage. Consistency and durability are also key benefits.

The Case for Tradition (Wood)

Wood remains the standard for a reason. It provides better insulation for the bee colony against heat and cold. Many beekeepers also believe bees are more inclined to build comb on natural wooden surfaces. The upfront cost of a frame-making machine is also substantial compared to simply buying wooden components.

Potential Downsides of Metal

Metal is a poor insulator, meaning it can get very hot in the summer and very cold in the winter, potentially stressing the colony. Depending on the type of metal and its coating, there can also be a risk of rust over time.

Is This Machine Right for Your Operation?

The decision to use such a machine is a strategic one that depends entirely on your goals and scale.

- If your primary focus is large-scale commercial production: This machine is a powerful investment for maximizing output, ensuring equipment longevity, and minimizing long-term labor costs.

- If your primary focus is hobby or small-scale beekeeping: The high initial investment and industrial output make this machine impractical. Manual assembly or purchasing pre-made wooden frames is a far more sensible choice.

- If your primary focus is pest resistance and durability: Metal frames produced by this machine offer a clear advantage over wood, which is susceptible to pests and physical damage.

Ultimately, choosing this technology means prioritizing industrial efficiency and durability over the traditional materials and methods of beekeeping.

Summary Table:

| Stage | Process | Key Outcome |

|---|---|---|

| 1. Input | Metal strip is loaded from a roll. | Raw material ready for shaping. |

| 2. Feeding | Machine pulls the strip into the shaping area. | Ensures continuous, steady production flow. |

| 3. Shaping | Strip passes through rollers and dies (roll forming). | Flat metal is bent into the final 3D sidebar profile. |

| 4. Cutting | Shaped metal is cut to the exact required length. | A single, finished sidebar is produced. |

| 5. Assembly | Metal sidebars are combined with top/bottom bars. | A complete, durable frame is created for the hive. |

Ready to Scale Your Apiary's Efficiency?

For commercial apiaries and beekeeping equipment distributors, the durability and high-volume output of automated metal frames are game-changers. HONESTBEE supplies the robust beekeeping supplies and equipment you need to build a more productive and resilient operation.

Contact HONESTBEE today to discuss how our wholesale-focused solutions can support your large-scale beekeeping goals.

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

People Also Ask

- Why is modern hive construction a highly sought-after skill? Master the Art of Cost-Effective Apiary Expansion

- What are the qualities of the bee frame forming machine? Durable, Efficient, and Built to Last

- What reliability and support are offered with the Beehive Frame Making Machine? Secure Your Production Investment

- What is the purpose of a small desktop bee frame forming machine? Automate Frame Assembly for Beekeepers

- Why are Langstroth and Dadant beehive frames popular choices for honey extractors? Maximize Your Honey Yield with Standardized Equipment