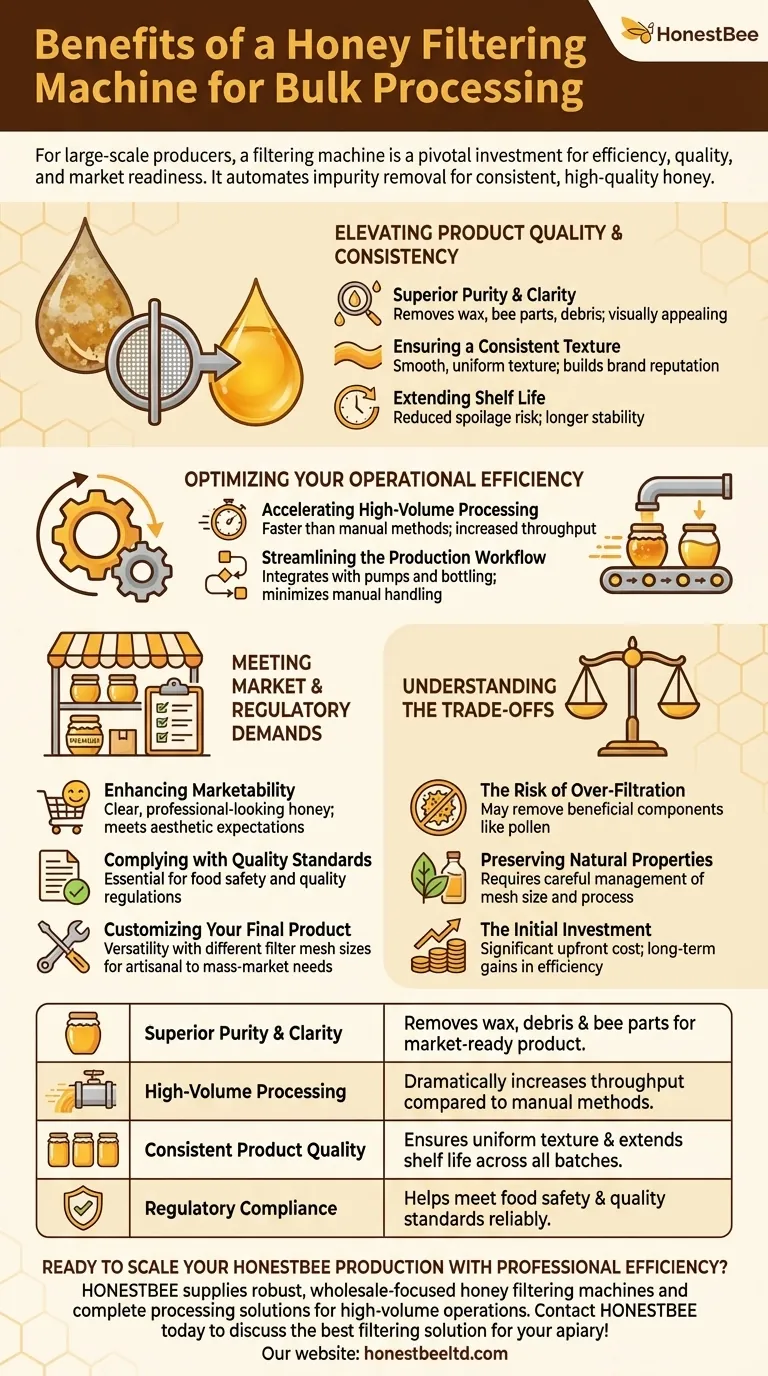

For any large-scale honey producer, a honey filtering machine is a pivotal investment that directly enhances operational efficiency, product quality, and market readiness. It automates the removal of impurities like wax particles, bee parts, and debris, allowing you to process significant volumes of honey quickly while ensuring a consistent, high-quality final product that is more appealing to consumers.

The core benefit of a honey filtering machine isn't just cleaning honey; it's about standardizing your product for the market. It transforms a variable, raw ingredient into a consistent, professional-grade product, unlocking significant gains in speed, cost-effectiveness, and consumer trust.

Elevating Product Quality and Consistency

A machine-based filtering system provides a level of control and uniformity that is difficult to achieve manually, especially across large batches. This consistency is the foundation of a professional honey brand.

Achieving Superior Purity and Clarity

The primary function of the filter is to remove unwanted physical impurities. This includes everything from wax cappings and bee parts to pollen and other field debris.

The result is a visually clear and appealing product, which is a key factor for many consumers when making a purchasing decision.

Ensuring a Consistent Texture

By removing solid particles, the machine ensures a smooth, uniform texture throughout every jar in a batch. This consistency is crucial for building brand reputation and customer loyalty.

Extending Shelf Life

The removal of contaminants and impurities also plays a role in the honey's stability. A cleaner product has a reduced risk of fermentation or spoilage, contributing to a longer and more reliable shelf life.

Optimizing Your Operational Efficiency

For bulk processing, time and labor are critical cost factors. Automation introduces significant advantages that directly impact your bottom line.

Accelerating High-Volume Processing

A filtering machine is designed to handle a large volume of honey far more quickly than manual methods using strainers and cloths.

This dramatic increase in throughput makes the entire extraction and bottling process more efficient and, at scale, more cost-effective.

Streamlining the Production Workflow

The filtering machine is a central component in an integrated processing line. It works seamlessly with pumps and bottling equipment to create a smooth, continuous flow from extractor to final container, minimizing manual handling and potential contamination.

Meeting Market and Regulatory Demands

Producing honey for a wider market involves meeting specific expectations from both consumers and regulatory bodies.

Enhancing Marketability

A clear, pure, and professional-looking honey is simply easier to sell. It meets the aesthetic expectations of the average retail customer and conveys a sense of quality and care.

Complying with Quality Standards

Clean, impurity-free honey is a prerequisite for meeting food safety and quality regulations. A reliable filtering process helps ensure your product consistently meets these essential standards.

Customizing Your Final Product

These machines offer valuable versatility. By using different filter mesh sizes, you can customize the level of filtration to meet specific market demands.

This allows you to produce everything from crystal-clear honey for mass-market retail to minimally filtered raw honey that retains more pollen for artisanal markets, all while maintaining efficiency.

Understanding the Trade-offs

While highly beneficial, it's important to approach this investment with a clear understanding of the potential considerations.

The Risk of Over-Filtration

Using extremely fine filters can remove beneficial components, most notably pollen. This can be a negative for consumers specifically seeking raw, unfiltered honey with its complete natural profile.

Preserving Natural Properties

While filtering can be done without pasteurization, preserving natural enzymes and flavors requires careful management. The key is to use the correct mesh size and process to clean the honey without stripping its valued characteristics.

The Initial Investment

A professional honey filtering machine represents a significant upfront capital expenditure. The return on this investment is realized through long-term gains in efficiency, labor reduction, and increased production capacity.

Making the Right Choice for Your Operation

Integrating a honey filtering machine is a strategic decision that should align with your business goals.

- If your primary focus is large-scale commercial retail: A filtering machine is essential for creating the visually clear, pure, and consistent product that mainstream consumers expect.

- If your primary focus is artisanal or raw honey: The machine still offers immense efficiency benefits, but you must use coarser mesh filters to preserve pollen and other natural characteristics your customers value.

- If your primary focus is maximizing operational efficiency: This equipment is a cornerstone investment that reduces manual labor, increases throughput, and makes your entire honey processing workflow more scalable and profitable.

Ultimately, a honey filtering machine is the tool that enables your operation to scale effectively while delivering a consistently professional product.

Summary Table:

| Key Benefit | Impact on Your Operation |

|---|---|

| Superior Purity & Clarity | Removes wax, debris & bee parts for a market-ready product. |

| High-Volume Processing | Dramatically increases throughput compared to manual methods. |

| Consistent Product Quality | Ensures uniform texture and extends shelf life across all batches. |

| Regulatory Compliance | Helps meet food safety and quality standards reliably. |

Ready to Scale Your Honey Production with Professional Efficiency?

For commercial apiaries and beekeeping equipment distributors, investing in the right equipment is key to profitability and growth. HONESTBEE supplies robust, wholesale-focused honey filtering machines and complete processing solutions designed for high-volume operations.

We help you achieve the consistent quality and operational efficiency your business needs to succeed in a competitive market. Contact HONESTBEE today to discuss the best filtering solution for your apiary!

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What is the filtration process for honey in a factory? Industrial Steps to Achieve Crystal-Clear Honey Quality

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment

- How should honey filtering equipment be properly maintained? Extend Equipment Life & Protect Honey Purity

- What role does industrial honey filtration play? Enhance Market Value with Professional Processing Equipment

- What is the function of a honey filtering machine in relation to air bubbles? Stabilize Your Honey Quality

- What specific role do Honey Purification and Filtration Systems play? Elevate Your Exports for Global Markets

- How does honey filtering equipment function? Elevate Your Post-Harvest Processing for Maximum Honey Purity

- What is the primary function of a honey disintegrator or filter press? Essential Purification for Quality Honey