The primary benefits of using styrofoam beehives center on their superior thermal insulation and significantly lighter weight. These two material properties lead to tangible improvements in colony health, overwintering success, and overall honey production when compared to traditional wooden hives.

While wooden hives offer natural appeal and customizability, the data shows that styrofoam hives provide a measurable performance advantage. The core of this advantage lies in creating a more stable internal environment, allowing bees to dedicate more energy to production and growth rather than temperature regulation.

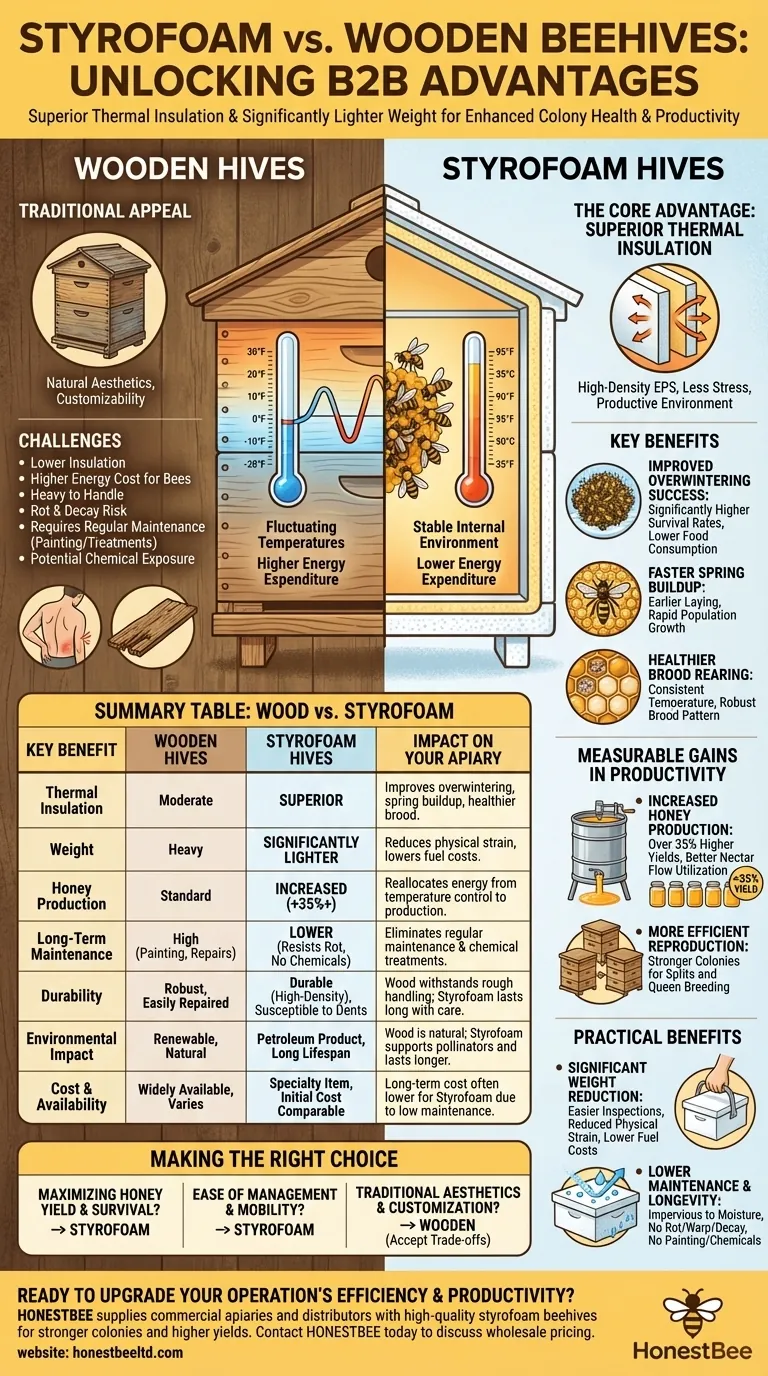

The Core Advantage: Superior Thermal Insulation

A beehive's ability to retain heat is its most critical performance factor. High-density expanded polystyrene (EPS), or styrofoam, excels in this area, creating a less stressful and more productive environment for the colony.

Improved Overwintering Success

Bees must maintain a cluster temperature of around 95°F (35°C) to survive the winter. The superior insulation of styrofoam dramatically reduces the energy bees must expend to generate this heat. This leads to lower food consumption and significantly higher colony survival rates through cold winters.

Faster Spring Buildup

Coming out of winter, a colony in an insulated hive can maintain its ideal brood-rearing temperature more easily. This allows the queen to begin laying earlier and the colony to build up its population much faster than one in a colder wooden hive.

Healthier Brood Rearing

A stable temperature is crucial for the healthy development of bee larvae. By minimizing temperature fluctuations, styrofoam helps ensure a consistent and robust brood pattern, leading to a stronger and more populous colony.

Measurable Gains in Productivity

The energy a colony saves on temperature control is directly reallocated to other vital tasks, resulting in clear and measurable gains for the beekeeper.

Increased Honey Production

With a larger, healthier workforce established earlier in the season, colonies in styrofoam hives can take better advantage of the main nectar flow. Studies and field reports consistently show styrofoam hives can increase honey yields by more than 35% over their wooden counterparts.

More Efficient Colony Reproduction

Stronger colonies are ideal for beekeepers looking to expand their operations. A colony that overwinters well and builds up quickly is a prime candidate for making splits or for use in queen breeding programs.

The Practical Benefits of Modern Materials

Beyond thermal performance, the material properties of styrofoam offer distinct advantages in hive management and long-term maintenance.

Significant Weight Reduction

Styrofoam hive components are dramatically lighter than wood. This makes lifting boxes for inspections and honey harvesting far easier on the beekeeper's back. For commercial operators, this weight savings reduces fuel consumption and can allow for the use of smaller, more efficient vehicles.

Lower Maintenance and Longevity

Styrofoam is impervious to moisture and will not rot, warp, or decay like wood. It is not susceptible to woodworm and does not require the regular painting or chemical treatments that wooden hives need to prolong their life.

A Healthier, More Controlled Environment

Because they don't rot, styrofoam hives eliminate the need for chemical wood preservatives. This avoids exposing the bees to potentially harmful substances, a risk present in some wooden hives, particularly older ones treated with phased-out chemicals like Creosote.

Understanding the Trade-offs: Wood vs. Styrofoam

To make an informed decision, it's critical to weigh the performance gains of styrofoam against the known benefits and drawbacks of both materials.

Durability and Handling

Wood is a robust material that can withstand rough handling. Styrofoam is softer and can be dented by hive tools or damaged by pests like mice if not properly protected. However, high-density EPS is quite durable and can last for many years with proper care.

Environmental Impact and Aesthetics

Many beekeepers are drawn to the traditional, natural look of wooden hives. As a renewable resource, wood also has strong environmental appeal. Styrofoam is a petroleum product, though its long lifespan and role in supporting vital pollinators can be considered an ecological benefit.

Cost and Availability

Wooden hives and their components are widely available from numerous suppliers. High-quality styrofoam hives are often considered a specialty item and may be harder to source locally. The initial investment can be comparable, but the long-term cost may be lower for styrofoam due to the lack of maintenance.

Customization and Repair

Wood is easily modified, allowing beekeepers to drill new entrances or make other custom alterations. Repairing a wooden box is straightforward. Styrofoam is less forgiving to modification and damage, though minor dents and cracks can often be repaired with glue.

Making the Right Choice for Your Goal

The best hive material is the one that aligns with your specific beekeeping objectives.

- If your primary focus is maximizing honey yield and colony survival: The superior thermal performance of styrofoam provides a distinct and proven advantage.

- If your primary focus is ease of management and mobility: The lightweight nature of styrofoam makes it the superior choice, especially for commercial or migratory beekeeping.

- If your primary focus is traditional aesthetics and hands-on customization: A well-maintained wooden hive remains a perfectly viable option, as long as you accept the trade-offs in thermal efficiency and maintenance.

By understanding these fundamental differences, you can confidently select the hive system that best serves your bees and your beekeeping goals.

Summary Table:

| Key Benefit | Impact on Your Apiary |

|---|---|

| Superior Thermal Insulation | Improves overwintering survival, accelerates spring buildup, and promotes healthier brood. |

| Significantly Lighter Weight | Reduces physical strain during inspections and lowers fuel costs for migratory operations. |

| Increased Honey Production | Colonies can achieve over 35% higher yields by reallocating energy from temperature control. |

| Lower Long-Term Maintenance | Resists rot, warping, and decay; eliminates the need for regular painting or chemical treatments. |

Ready to upgrade your operation's efficiency and productivity?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, performance-driven styrofoam beehives through our wholesale-focused operations. By switching to our insulated hives, you can expect stronger colonies, significantly higher honey yields, and reduced long-term maintenance costs.

Contact HONESTBEE today to discuss wholesale pricing and how our equipment can help your business thrive.

Visual Guide

Related Products

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Professional Grade Foldable Beehive Handles

- Professional Drop-Style Hive Handles for Beekeeping

- Endless Loop Ratchet Hive Strap

- Premium Ventilated Goatskin Beekeeping Gloves with Full 3-Layer Mesh Sleeve

People Also Ask

- What is the best length for straps used around beehives? Why 12 Feet is the Industry Standard

- What is the proper method for installing a cam buckle strap on a beehive? Secure Your Hives for Maximum Stability

- What maintenance is required for hive straps? A Guide to Cam Buckle vs. Ratchet Strap Care

- How should a cam buckle strap be installed for optimal performance? Master the Leverage for Maximum Tension

- How can a beehive be physically secured against harsh winter weather? Expert Winterizing Strategies for Your Apiary