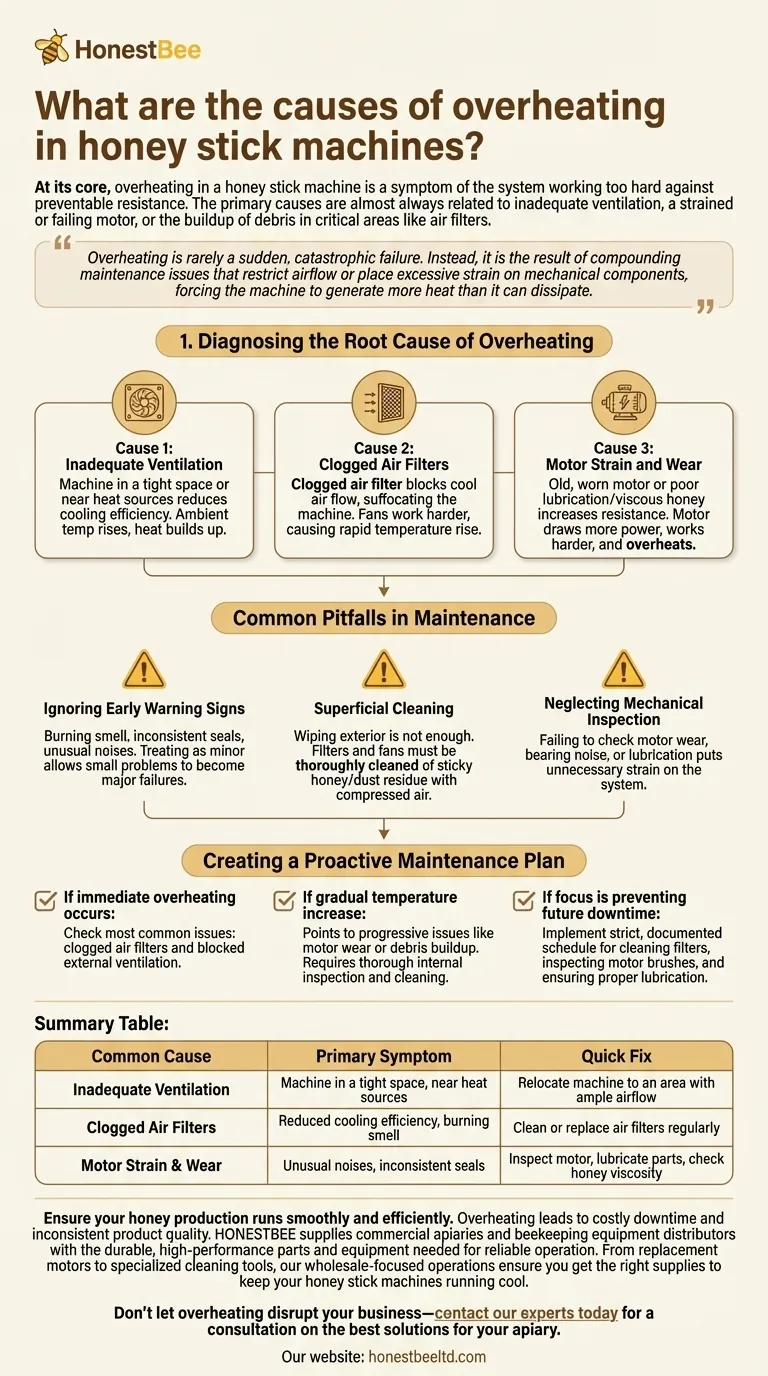

At its core, overheating in a honey stick machine is a symptom of the system working too hard against preventable resistance. The primary causes are almost always related to inadequate ventilation, a strained or failing motor, or the buildup of debris in critical areas like air filters.

Overheating is rarely a sudden, catastrophic failure. Instead, it is the result of compounding maintenance issues that restrict airflow or place excessive strain on mechanical components, forcing the machine to generate more heat than it can dissipate.

Diagnosing the Root Cause of Overheating

To solve the problem, you must first identify the specific point of failure. Overheating is a symptom, and these are the most common underlying causes.

Cause 1: Inadequate Ventilation

A honey stick machine generates significant heat from its sealing elements and motor during normal operation. The machine's chassis and fans are designed to constantly dissipate this thermal energy.

If the machine is placed in a tight space, against a wall, or near other heat-producing equipment, the ambient air temperature rises. This reduces the cooling system's efficiency, causing heat to build up internally.

Cause 2: Clogged Air Filters

Air filters are the machine's first line of defense, preventing airborne dust and debris from reaching sensitive internal components.

Over time, these filters become saturated. A clogged air filter physically blocks the flow of cool air, effectively suffocating the machine. The internal fans are forced to work harder with less effect, leading directly to a rapid increase in component temperature.

Cause 3: Motor Strain and Wear

The machine's motor drives the mechanical processes of filling and sealing. If the motor is old and its internal components are worn, it operates less efficiently and generates more waste heat.

Furthermore, issues like improperly lubricated parts or using honey that is too viscous can dramatically increase mechanical resistance. This forces the motor to draw more power and work harder, causing it to overheat as it strains against the load.

Common Pitfalls in Maintenance

Addressing the symptom without understanding the cause can lead to recurring failures. Avoiding these common mistakes is critical for long-term reliability.

Ignoring Early Warning Signs

Overheating is often preceded by other indicators. Operators may notice a slight burning smell, inconsistent seals on the honey sticks, or unusual noises from the motor. Treating these as minor annoyances instead of diagnostic clues allows a small problem to become a major failure.

Superficial Cleaning

Simply wiping down the exterior of the machine is not sufficient. Honey is sticky and can combine with dust to create a stubborn residue. Air filters and fan blades must be thoroughly cleaned to remove all obstructions. Compressed air is often necessary to clear debris from hard-to-reach internal areas.

Neglecting Mechanical Inspection

A clean machine can still overheat if the mechanical components are failing. Failing to periodically check for signs of motor wear, listen for bearing noise, or ensure all moving parts are properly lubricated puts unnecessary strain on the entire system.

Creating a Proactive Maintenance Plan

Instead of reacting to failures, a routine checklist prevents them from occurring. Tailor your actions to the specific goal.

- If your immediate goal is to fix an overheated machine: Start by checking for the most common and easily fixed issues—clogged air filters and blocked external ventilation.

- If you notice a gradual increase in operating temperature: This points to a progressive issue like motor wear or slow debris buildup, requiring a more thorough internal inspection and cleaning.

- If your primary focus is preventing future downtime: Implement a strict, documented schedule for cleaning filters, inspecting motor brushes, and ensuring proper lubrication.

By treating the machine's cooling system as a critical component, you transform maintenance from a chore into a tool for ensuring consistent and reliable production.

Summary Table:

| Common Cause | Primary Symptom | Quick Fix |

|---|---|---|

| Inadequate Ventilation | Machine in a tight space, near heat sources | Relocate machine to an area with ample airflow |

| Clogged Air Filters | Reduced cooling efficiency, burning smell | Clean or replace air filters regularly |

| Motor Strain & Wear | Unusual noises, inconsistent seals | Inspect motor, lubricate parts, check honey viscosity |

Ensure your honey production runs smoothly and efficiently. Overheating leads to costly downtime and inconsistent product quality. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, high-performance parts and equipment needed for reliable operation. From replacement motors to specialized cleaning tools, our wholesale-focused operations ensure you get the right supplies to keep your honey stick machines running cool.

Don't let overheating disrupt your business—contact our experts today for a consultation on the best solutions for your apiary.

Visual Guide

Related Products

- Modern Honeycomb Pattern Wooden Honey Dipper for Stirring and Drizzling

- 10L Stainless Steel Electric Honey Press Machine

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Automatic Honey Frame Uncapper Machine for Beekeeping

People Also Ask

- What is the value of automated honey filling machines for commercial apiaries? Maximize Peak Harvest Profitability

- How can contamination in filled honey be prevented? A 3-Step Strategy for Pure, Shelf-Stable Honey

- How does automatic filling equipment ensure the quality of honey collected from wild floral sources? | HONESTBEE Guide

- How do honey filtration and filling machinery contribute to industrialization? Scale Your Commercial Honey Production

- What is the significance of high-precision honey-filling machines? Preserve Quality and Maximize Efficiency

- Why is temperature a factor during the filtering and bottling of infused honey? Mastering Flow and Quality Control

- What role do high-precision honey filling machines play in processing? Enhance Purity and Commercial Scalability

- What role does an industrial-grade honey filling machine play in maintaining the stability of medicinal honey?