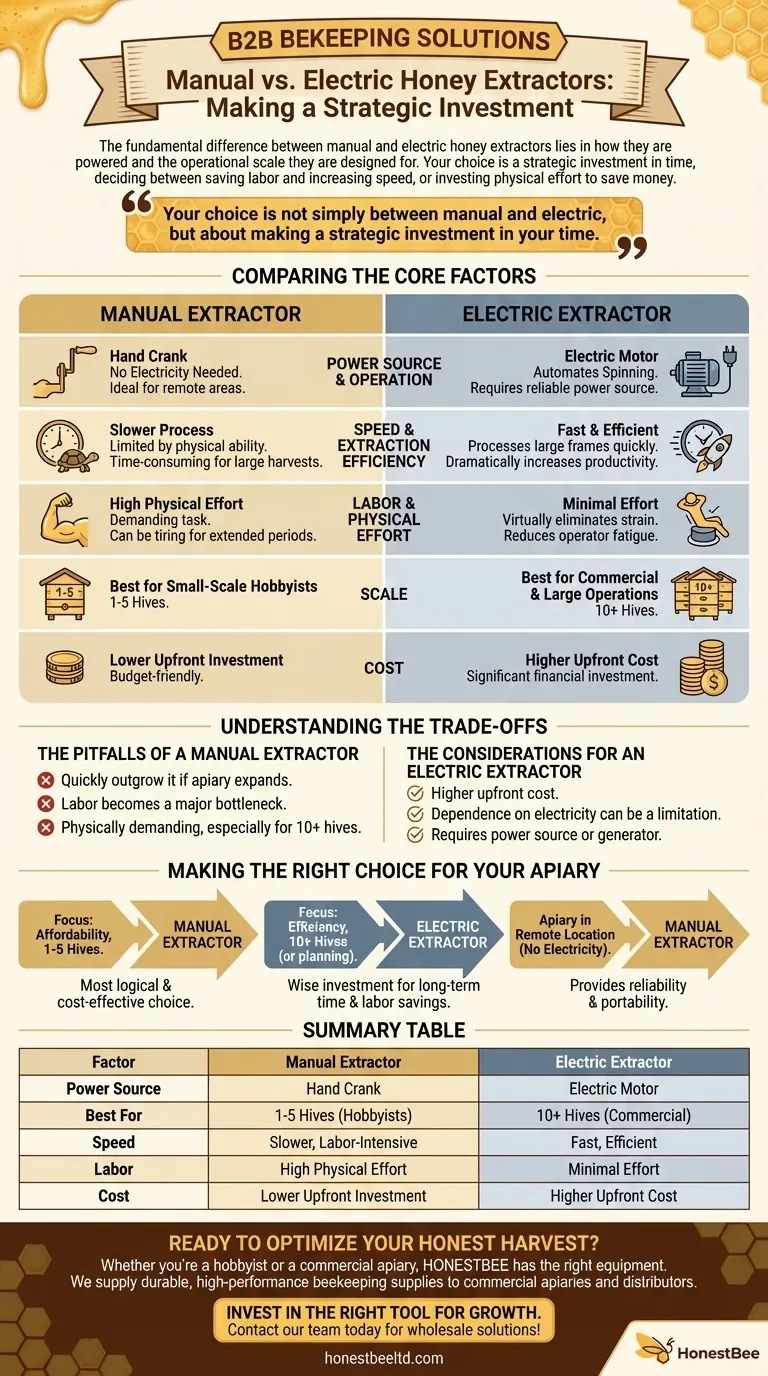

The fundamental difference between manual and electric honey extractors lies in how they are powered and the operational scale they are designed for. A manual extractor uses a hand crank, making it a budget-friendly but labor-intensive option ideal for small-scale hobbyists. An electric extractor uses a motor, offering speed and efficiency at a higher cost, which is necessary for larger or commercial beekeeping operations.

Your choice is not simply between manual and electric, but about making a strategic investment in your time. You are deciding whether to spend money to save labor and increase speed, or to save money by investing your own physical effort and time.

Comparing the Core Factors

To select the right extractor, you must weigh five critical factors: power, speed, labor, scale, and cost. Each directly impacts the efficiency and enjoyment of your honey harvest.

Power Source and Operation

A manual extractor is operated by a hand crank. This simple, mechanical design means it requires no electricity and can be used anywhere, which is a significant advantage in remote or off-grid apiaries.

An electric extractor is powered by a motor. This automates the spinning process, providing consistent speed and freeing the beekeeper from physical work. However, it requires a reliable power source, such as a mains outlet or a generator.

Speed and Extraction Efficiency

The most significant advantage of an electric extractor is its speed. It can process a large number of frames quickly and consistently, dramatically increasing the productivity of your harvest.

Manual extractors are inherently slower. The speed is limited by your physical ability to turn the crank, making the process much more time-consuming, especially when you have many frames to extract.

Labor and Physical Effort

Using a manual extractor is a physically demanding task. Cranking for an extended period can be tiring, turning a large harvest into a significant workout.

Electric extractors virtually eliminate physical strain. With the press of a button, the machine does all the work, reducing operator fatigue and making the extraction process far easier.

Understanding the Trade-offs

Neither extractor is universally "better." Each comes with a distinct set of compromises that you must align with your specific situation.

The Pitfalls of a Manual Extractor

While excellent for beginners, the primary drawback of a manual extractor is that you may quickly outgrow it. If your apiary expands beyond a few hives, the time and labor required for extraction can become a major bottleneck.

The physical effort is not trivial. For beekeepers with physical limitations or those processing more than 5-10 hives, a manual extractor can make harvest day a grueling experience.

The Considerations for an Electric Extractor

The main barrier to an electric extractor is the higher upfront cost. It represents a more significant financial investment in your beekeeping equipment.

Furthermore, its dependence on electricity can be a limitation. If your honey house or extraction site lacks power, a manual extractor is the more practical choice unless you plan to use a portable generator.

Making the Right Choice for Your Apiary

Your decision should be a direct reflection of your budget, your physical capacity, and, most importantly, the current and future scale of your beekeeping.

- If your primary focus is affordability and you manage 1-5 hives: A manual extractor is the most logical and cost-effective choice for your needs.

- If your primary focus is efficiency and you manage 10+ hives (or plan to): An electric extractor is a wise investment that will save you significant time and labor in the long run.

- If your apiary is in a remote location without electricity: A manual extractor provides the reliability and portability you need to get the job done anywhere.

Ultimately, choosing the right extractor is about selecting the tool that best supports your beekeeping goals and makes the reward of the harvest a pleasure, not a chore.

Summary Table:

| Factor | Manual Extractor | Electric Extractor |

|---|---|---|

| Power Source | Hand Crank | Electric Motor |

| Best For | 1-5 Hives (Hobbyists) | 10+ Hives (Commercial) |

| Speed | Slower, Labor-Intensive | Fast, Efficient |

| Labor | High Physical Effort | Minimal Effort |

| Cost | Lower Upfront Investment | Higher Upfront Cost |

Ready to Optimize Your Honey Harvest?

Whether you're a hobbyist looking for a reliable manual extractor or a commercial apiary needing the efficiency of an electric model, HONESTBEE has the right equipment for you. We supply durable, high-performance beekeeping supplies and extractors to commercial apiaries and distributors through our wholesale-focused operations.

Invest in the right tool for your operation's growth and efficiency. Contact our team today to discuss your needs and get a quote on the best extraction solution for your apiary!

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- Why are high-efficiency centrifugal extraction and temperature-controlled machines necessary for high-standard honey?

- How can beekeepers manage honey collection to separate different honey types? Master Timing for Premium Honey Harvests

- What are the economic advantages of using professional honey extraction machinery? Boost Efficiency and Global Pricing

- What are the core advantages of centrifugal automatic honey extractors? Maximize Yield and Preserve Your Honeycomb

- How does honey extraction equipment maintain quality in complex climates? Ensure purity with precision processing.

- How do professional honey extraction and filtration systems contribute to improving the quality of the final honey product?

- What is the purpose of an electric honey extractor? Scale Your Harvest with Ease

- What are the primary production advantages of using automated centrifugal equipment in honey extraction? Maximize Yield