The primary environmental benefit of a solar wax melter is its ability to process beeswax using only the sun's renewable energy. This completely eliminates the need for electricity or fossil fuels for this task, directly reducing the carbon footprint of your beekeeping operation and removing your dependence on conventional energy grids.

A solar wax melter is more than just an energy-saving tool; it's a device that transforms a waste byproduct into a valuable resource using zero emissions. It embodies the principles of a circular economy, making it a cornerstone of a truly sustainable apiary.

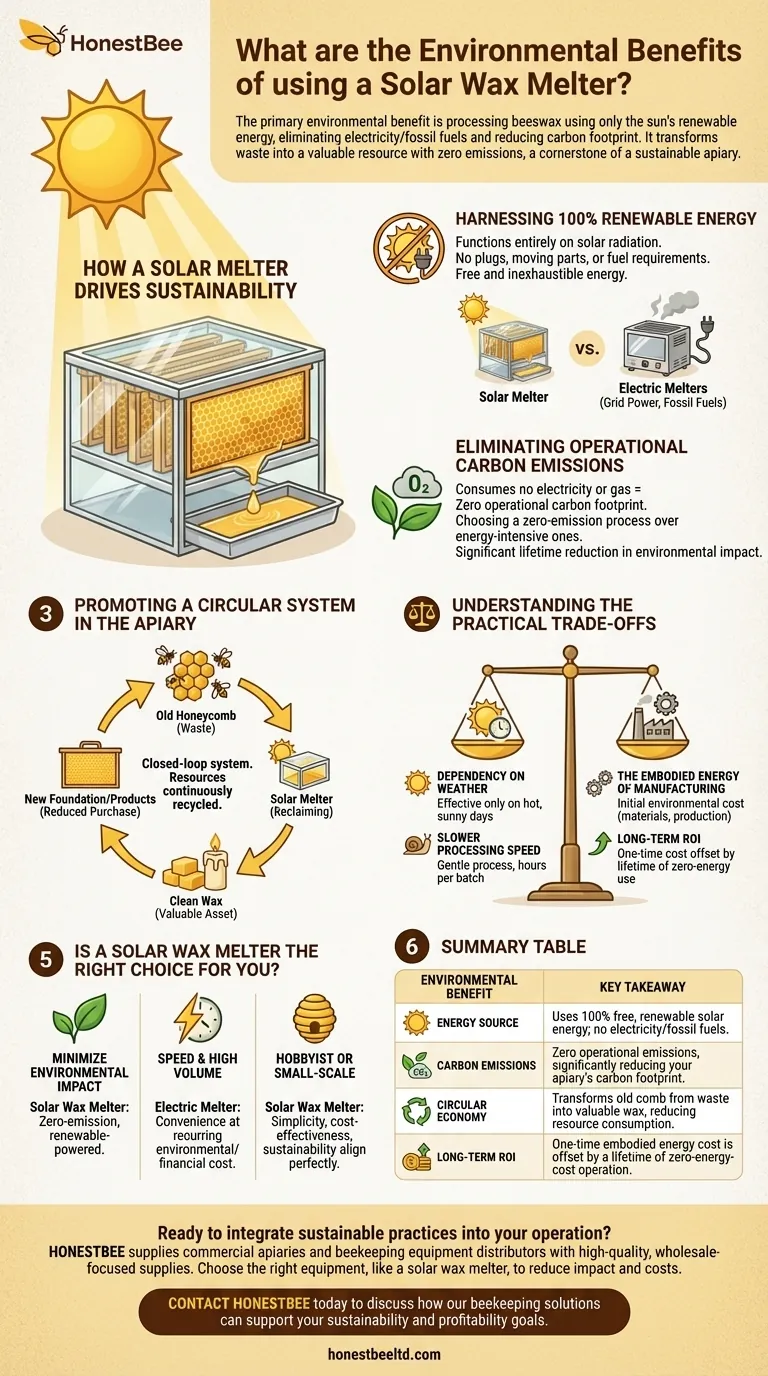

How a Solar Melter Drives Sustainability

A solar wax melter is a simple yet powerful example of passive solar design. It works by capturing and concentrating the sun's heat under a glass or polycarbonate lid to render clean wax from old comb.

Harnessing 100% Renewable Energy

A solar melter has no plugs, moving parts, or fuel requirements. It functions entirely on solar radiation, a free and inexhaustible energy source.

This stands in stark contrast to electric melters, which draw power from the grid. That electricity is often generated by burning fossil fuels, contributing to greenhouse gas emissions.

Eliminating Operational Carbon Emissions

Because it consumes no electricity or gas, the operational carbon footprint of a solar wax melter is zero. Each time you use it, you are choosing a zero-emission process over an energy-intensive one.

Over the lifetime of the equipment, this results in a significant reduction in your operation's overall environmental impact.

Promoting a Circular System in the Apiary

Beekeeping naturally produces old, dark honeycombs that must be culled from the hive. A solar melter allows you to turn this "waste" into a valuable asset.

By reclaiming this wax, you reduce the need to purchase new beeswax and prevent old comb from being discarded. This creates a closed-loop system where resources are continuously recycled within your own operation.

Understanding the Practical Trade-offs

While environmentally superior, a solar wax melter is not without its operational limitations. Objectivity requires acknowledging these trade-offs.

Dependency on Weather

The most significant limitation is its complete reliance on the sun. The melter is only effective on hot, sunny days.

This means you cannot process wax on-demand. It requires planning and patience, whereas an electric unit can run anytime, day or night, in any weather.

Slower Processing Speed

Solar melting is a gentle and slow process. It can take several hours to render the wax from a batch of frames.

For large-scale commercial beekeepers who need to process hundreds of frames quickly, the throughput of a solar melter may be insufficient for their needs.

The Embodied Energy of Manufacturing

Like any manufactured product, a solar melter has an initial environmental cost, known as embodied energy, from the sourcing of its raw materials (metal, glass) and its production.

However, this is a one-time cost. It is quickly offset by a lifetime of zero-emission, zero-energy-cost operation, making its long-term environmental return on investment exceptionally high.

Is a Solar Wax Melter the Right Choice for You?

Choosing your wax processing method depends on balancing your operational scale, your need for speed, and your sustainability goals.

- If your primary focus is minimizing your environmental impact: A solar wax melter is the definitive choice, offering a zero-emission, renewable-powered solution.

- If your primary focus is on-demand speed and high volume: An electric melter provides convenience but at a recurring environmental and financial cost for the energy consumed.

- If you are a hobbyist or small-scale beekeeper: The simplicity, cost-effectiveness, and sustainability of a solar melter align perfectly with the scale and ethos of your operation.

Ultimately, adopting a solar wax melter is a powerful step toward a more self-sufficient and ecologically responsible beekeeping practice.

Summary Table:

| Environmental Benefit | Key Takeaway |

|---|---|

| Energy Source | Uses 100% free, renewable solar energy; no electricity or fossil fuels. |

| Carbon Emissions | Zero operational emissions, significantly reducing your apiary's carbon footprint. |

| Circular Economy | Transforms old comb from waste into valuable wax, reducing resource consumption. |

| Long-Term ROI | One-time embodied energy cost is offset by a lifetime of zero-energy-cost operation. |

Ready to integrate sustainable practices into your operation?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused supplies needed for a modern, eco-conscious business. By choosing the right equipment, like a solar wax melter, you can significantly reduce your environmental impact and operating costs.

Contact HONESTBEE today to discuss how our beekeeping solutions can support your sustainability and profitability goals.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers