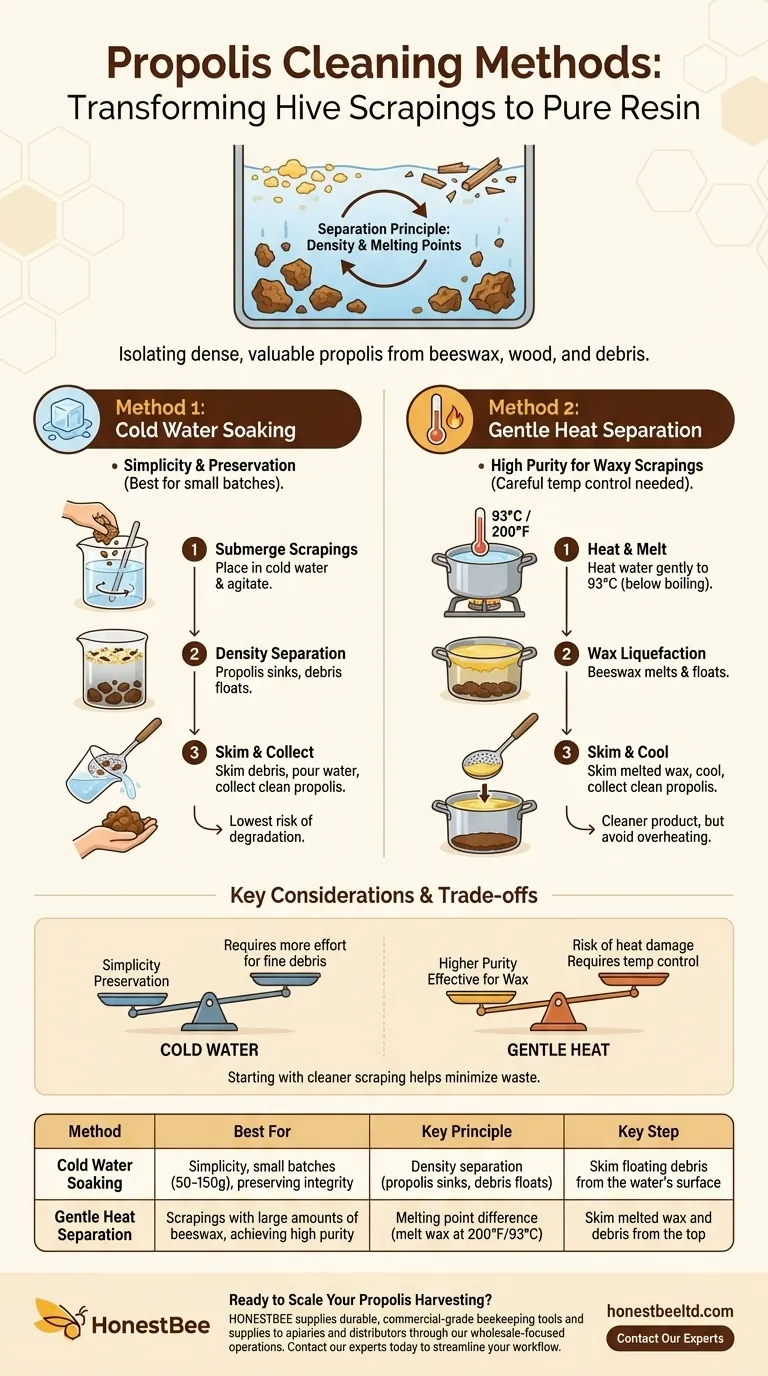

The two primary methods for cleaning propolis from hive scrapings are cold water soaking and gentle heating in water. Both techniques leverage the physical properties of propolis and its common contaminants, like beeswax and wood splinters, to achieve separation. The goal is to isolate the dense, valuable propolis resin from lighter materials.

The core principle of cleaning propolis is separation. By using water, you can exploit differences in density and melting points to isolate the pure propolis from beeswax, wood, and other hive debris.

Understanding Your Raw Material

Before cleaning, it's essential to understand what you're working with. Propolis scraped from a hive is rarely pure and requires processing to become a usable product.

The Composition of Hive Scrapings

Hive scrapings are a mixture of materials. Your goal is to separate the propolis, a sticky resinous substance, from the contaminants.

These contaminants typically include beeswax, wood splinters from the hive bodies, and other incidental hive debris.

The Goal of Cleaning

The cleaning process is designed to remove these unwanted materials. A successful cleaning leaves you with a pure, consolidated chunk of propolis that is ready for tincturing, storage, or other uses.

Method 1: Cold Water Soaking

This is the simplest method and relies entirely on the fact that propolis is denser than water and most of its contaminants.

The Principle of Density

When placed in water, propolis will sink to the bottom. In contrast, beeswax, small wood particles, and other lighter debris will float to the surface.

Step-by-Step Process

First, place your raw propolis scrapings in a container of cold water. Agitate the mixture to break up the clump and allow the materials to separate.

Skim the floating debris from the surface. Once all contaminants have been removed, you can pour off the water and collect the clean propolis from the bottom of the container.

Method 2: Gentle Heat Separation

This method is particularly effective when your scrapings contain a significant amount of beeswax. It uses low heat to melt the wax, making it easier to remove.

Leveraging Melting Points

Beeswax melts at a much lower temperature than propolis. By gently heating the mixture in water, you can liquefy the wax without damaging the propolis.

Step-by-Step Process

Place your scrapings in a pot of water and heat it gently. The reference suggests a temperature of 200°F (93°C), which is just below boiling.

As the mixture heats, the wax will melt and float to the top along with other debris. Skim this layer off the surface. After removing the contaminants, allow the water to cool and collect the clean propolis from the bottom.

Key Considerations and Trade-offs

Choosing the right method and executing it properly ensures you get a high-quality final product without unnecessary waste.

Avoiding Excessive Heat

While the gentle heat method is effective, be cautious. Overheating propolis can potentially degrade some of its beneficial volatile compounds. Never boil the mixture.

Purity vs. Simplicity

The cold water method is the safest for preserving the full integrity of the propolis but may require more effort to remove very fine debris.

The gentle heat method often results in a cleaner final product, especially with waxy scrapings, but requires careful temperature control.

The Importance of Collection

The cleaning process starts at the hive. Using a hive tool to carefully scrape away propolis and burr comb helps minimize the amount of wood and paint chips you have to remove later.

Making the Right Choice for Your Goal

Your approach should be determined by the composition of your scrapings and your intended use for the propolis.

- If your primary focus is simplicity and preservation: Use the cold water soaking method, as it requires no special equipment and poses no risk of heat damage.

- If your scrapings contain a large amount of beeswax: The gentle heat separation method will be far more effective at removing the wax contamination.

- If you are processing a very small amount: Cold water soaking is the most practical and efficient choice for small batches of 50-150g.

By applying these simple separation techniques, you can effectively transform raw hive scrapings into a clean and valuable product.

Summary Table:

| Method | Best For | Key Principle | Key Step |

|---|---|---|---|

| Cold Water Soaking | Simplicity, small batches (50-150g), preserving integrity | Density separation (propolis sinks, debris floats) | Skim floating debris from the water's surface |

| Gentle Heat Separation | Scrapings with large amounts of beeswax, achieving high purity | Melting point difference (melt wax at 200°F/93°C) | Skim melted wax and debris from the top |

Ready to Scale Your Propolis Harvesting?

Efficient propolis processing starts with high-quality equipment. HONESTBEE supplies durable, commercial-grade beekeeping tools and supplies to apiaries and distributors through our wholesale-focused operations.

Contact our experts today to discuss how our products can help you streamline your workflow and maximize the value of your hive products.

Visual Guide

Related Products

- Professional Wide Blade Honey Scraper for Beekeeping and Honey Processing

- Wooden Queen Bee Excluder for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Heavy-Duty Galvanized Steel W-Style Pallet Clip

People Also Ask

- What is the technical role of industrial-grade propolis extraction equipment? Master High-Purity Product Conversion

- How is propolis cleaned after harvesting? A Step-by-Step Guide to Purity

- What is the technical function of a plastic propolis trap? Enhance Hive Health & Varroa Control

- What do honey bees actually collect to make propolis? Harnessing Plant Resins for Hive Health

- What is the primary purpose of using professional plastic propolis collection traps? Achieve High-Purity Raw Material

- Why is a specific wooden frame required when installing a propolis screen? Optimize Your Propolis Harvest Efficiency

- How is propolis removed from a propolis trap after collection? The Best Way to Harvest Clean Propolis Fast

- Why is the choice of solvent critical for safety when performing propolis extraction? Ensuring Tissue Safety