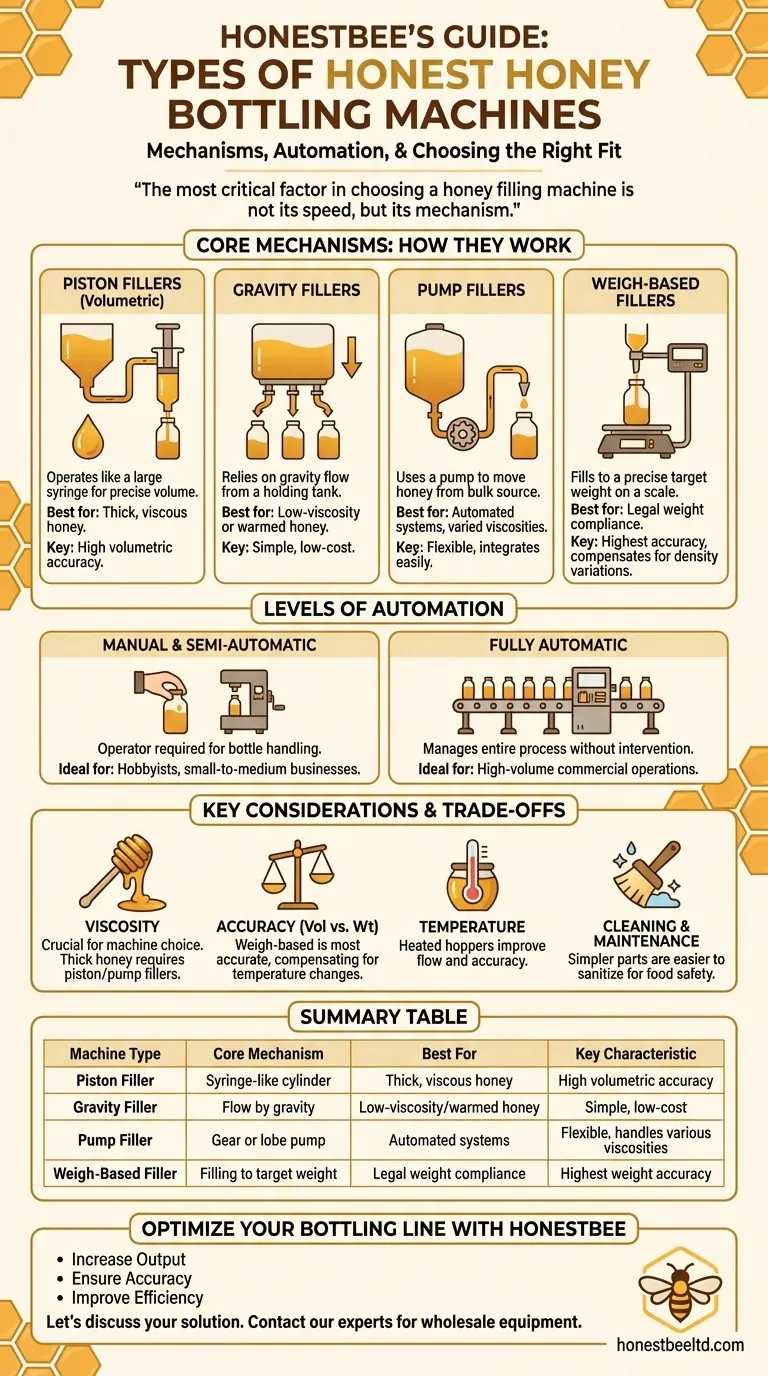

At their core, honey bottling machines are distinguished by their filling mechanism, not just their level of automation. The primary types are piston fillers (volumetric), gravity fillers, pump fillers, and weigh-based fillers. Each is designed to handle honey's unique viscosity and meet different production scales, from small hobbyist setups to large commercial operations.

The most critical factor in choosing a honey filling machine is not its speed, but its mechanism. Your honey's viscosity and your required fill accuracy (by volume or weight) will determine whether a piston, gravity, pump, or weigh-based filler is the right tool for your operation.

How Honey Filling Machines Work: The Core Mechanisms

Understanding the method each machine uses to dispense honey is the key to selecting the correct one. The mechanism dictates the machine's suitability for different honey types and production volumes.

Piston Fillers (Volumetric Filling)

A piston filler is one of the most common and effective types for honey. It operates like a large syringe, drawing a precise amount of honey into a cylinder and then pushing that exact volume into the container.

This method is highly accurate for volumetric filling and is especially well-suited for thick, viscous products like honey.

Gravity Fillers

A gravity filler is the simplest mechanism. It consists of a holding tank positioned above the filling nozzles. When a valve opens, gravity causes the honey to flow down into the bottles.

These are best for lower-viscosity or warmed honey and are typically used in manual or semi-automatic setups for small-scale beekeepers due to their simplicity and lower cost.

Pump Fillers

Pump fillers use a pump (such as a gear or lobe pump) to move honey from a bulk tank through the filling nozzles. The amount of product dispensed can be controlled by the timing of the pump's operation.

This type is very flexible, can handle a wide range of viscosities, and is easily integrated into automated systems where honey is drawn from large drums or tanks.

Weigh-Based Fillers

Also known as weighing filling machines, these systems fill containers to a precise target weight rather than a volume. Each bottling station sits on a load cell or scale.

The filler dispenses honey until the scale registers the correct weight, then shuts off the flow. This is the most accurate method, as it compensates for any variations in honey density caused by temperature changes or air bubbles.

Choosing Your Level of Automation

The filling mechanisms above can be integrated into systems with varying degrees of automation, which directly impacts labor costs, speed, and initial investment.

Manual & Semi-Automatic Systems

Manual systems require an operator to place the bottle, activate the fill, and remove the bottle. Semi-automatic systems might automate the filling process itself, but still require an operator to manually handle the containers.

These are ideal for hobbyists and small-to-medium businesses where production volume doesn't justify the cost of full automation.

Fully Automatic Systems

A fully automatic system manages the entire process. Conveyors move bottles into place, sensors trigger the fill, and the filled bottles are moved downstream for capping and labeling without operator intervention.

These machines are built for high-volume commercial operations where efficiency, consistency, and scalability are the primary goals.

Understanding the Trade-offs and Key Considerations

Choosing a machine involves more than just picking a type. Several factors will dictate your success.

Viscosity is Everything

Honey's thickness is the single most important consideration. A thick, crystallized honey will clog a simple gravity filler but can be handled easily by a powerful piston or pump filler.

Accuracy: Volume vs. Weight

Honey is legally sold by weight, not volume. While volumetric fillers (like piston machines) are very consistent, any change in honey's temperature will alter its density, changing the final weight. Weigh-based fillers eliminate this issue, ensuring every bottle meets its label weight.

Temperature Control

Honey flows much more easily when it is warm. Many professional-grade honey fillers incorporate a heated hopper or tank to keep the honey at a consistent, workable temperature, which improves both speed and accuracy.

Cleaning and Maintenance

Honey is sticky and can be difficult to clean. Consider how easily a machine can be disassembled and sanitized. Systems with fewer complex parts are generally easier to maintain, which is a critical factor for food safety.

Making the Right Choice for Your Operation

Your ideal machine depends entirely on your scale, product, and goals.

- If you are a hobbyist or small-scale producer: A manual gravity filler or a small, tabletop manual piston filler offers the best balance of affordability and control.

- If you are a growing mid-sized business: A semi-automatic piston filler or pump filler provides a significant boost in efficiency and consistency over manual methods.

- If you are a large commercial operation: A fully automatic line, likely using a rotary piston filler or a multi-head weigh filler, is necessary to meet high production demands.

- If your product's final weight accuracy is paramount: A weigh-based filling system is the only choice to guarantee legal compliance and prevent product giveaway.

By understanding these core principles, you can confidently select the machine that serves as a foundation for your business's growth.

Summary Table:

| Machine Type | Core Mechanism | Best For | Key Characteristic |

|---|---|---|---|

| Piston Filler | Syringe-like cylinder | Thick, viscous honey | High volumetric accuracy |

| Gravity Filler | Flow by gravity | Low-viscosity/warmed honey | Simple, low-cost |

| Pump Filler | Gear or lobe pump | Automated systems | Flexible, handles various viscosities |

| Weigh-Based Filler | Filling to target weight | Legal weight compliance | Highest weight accuracy |

Ready to Optimize Your Honey Bottling Line?

Choosing the right equipment is the foundation of an efficient and profitable operation. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the robust, high-performance bottling machines they need to scale.

We help you:

- Increase Output with machines matched to your production volume.

- Ensure Accuracy with fillers designed for honey's unique properties.

- Improve Efficiency by reducing labor and minimizing product waste.

Let's discuss the best solution for your business. Contact our experts today for a personalized consultation on our wholesale-focused honey bottling equipment.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- How do automated honey-filling and labeling machines prevent honey laundering? Secure Your Global Supply Chain Integrity

- What is a Multi Lane Honey Sachet Packing Machine and when is it used? Maximize Your High-Volume Honey Production

- How do automatic honey-filling machines ensure market competitiveness? Elevate Your Brand and Profitability

- Why is industrial-grade honey filling equipment essential? Secure Global Trade with Precise Automation

- What are the technical advantages of using industrial-grade honey filling machines compared to manual filling processes?

- What are the technical considerations for the multi-point sampling design of industrial filling tanks? Ensure Precision

- What economic benefits do automated honey-filling machines provide? Boost Efficiency in High-Yield Honey Production

- How do automatic Honey-filling Machines improve processing standards? Elevate Accuracy and Hygiene in Large Apiaries