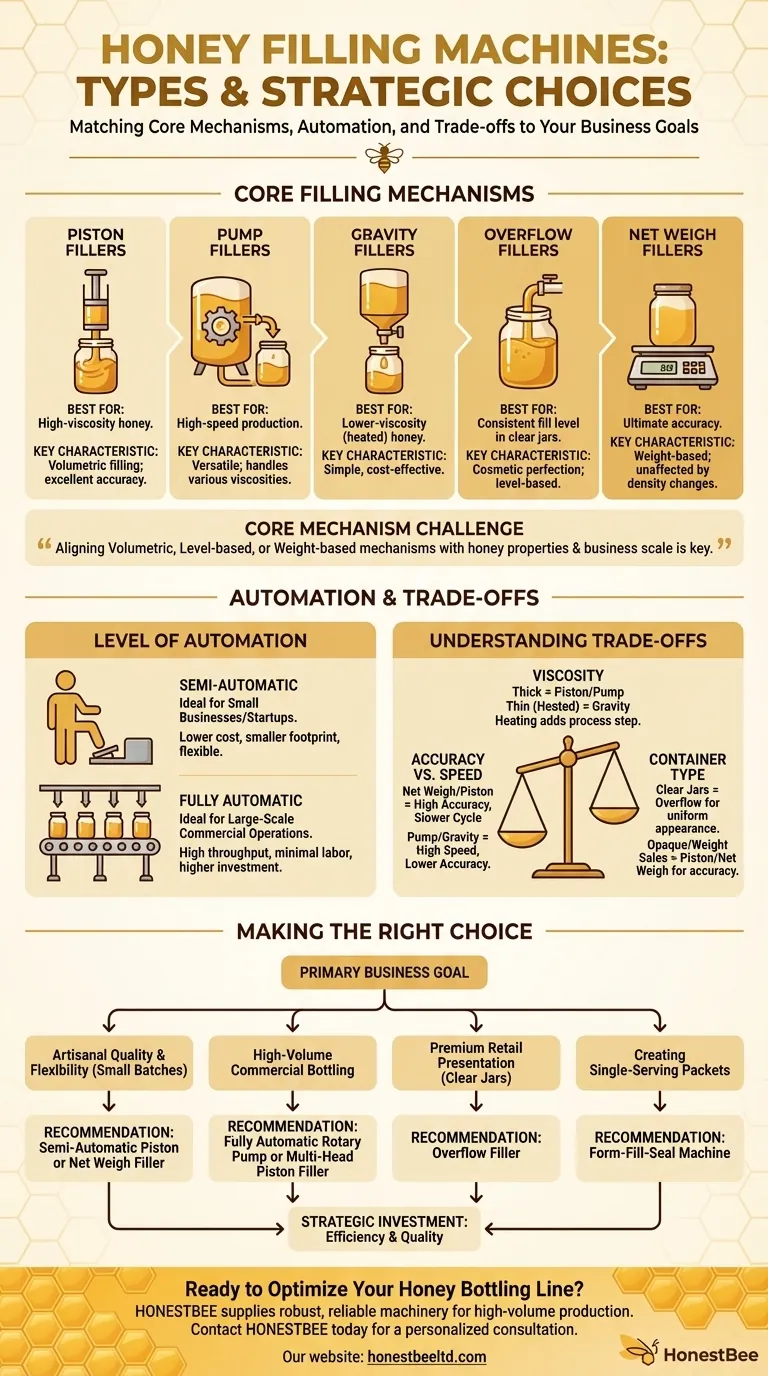

At its core, a honey filling machine operates on one of five primary principles. The most common types are piston fillers, which are ideal for honey's high viscosity, followed by pump fillers, gravity fillers, overflow fillers, and net weigh fillers. Each is engineered to handle different production speeds, container types, and honey consistencies.

The challenge isn't just knowing the types of machines, but understanding how their core mechanism—volumetric, level-based, or weight-based—aligns with your honey's properties and your business's scale. The right choice balances accuracy, speed, and cost.

Core Filling Mechanisms Explained

The "type" of honey filler is best defined by how it measures and dispenses the product. Each method is suited to different operational priorities.

Piston Fillers: The Standard for Viscosity

A piston filler uses a cylinder and a piston to pull in a precise amount of honey and then push it out into a container. This is a form of volumetric filling.

Because it actively forces the product, this mechanism is extremely effective for thick, viscous liquids like honey. It offers a high degree of accuracy and repeatability.

Pump Fillers: Engineered for Speed

Pump fillers use a gear, lobe, or progressive cavity pump to move honey from a bulk tank to the container. The amount dispensed is controlled by the timing or the number of pump rotations.

This method is well-suited for high-speed, continuous production lines and can handle a wide range of viscosities, making it a versatile choice for larger operations.

Gravity Fillers: Simplicity for Lower Viscosity

A gravity filler holds the honey in a tank above the filling nozzles. When a valve opens, gravity causes the honey to flow into the container below.

This is the simplest and often most cost-effective mechanism. However, it works best with lower-viscosity honey, often requiring the product to be heated to improve flow rate and ensure accuracy.

Overflow Fillers: For a Perfect Cosmetic Fill

Unlike other methods, an overflow filler is not designed to deliver a precise volume. Instead, it fills each container to the exact same level.

It works by pumping honey into the bottle until it overflows through a return port. This is ideal for transparent containers where a consistent, visually appealing fill height is more important than precise volumetric accuracy.

Net Weigh Fillers: Unmatched Accuracy

A net weigh filler dispenses product based on weight, not volume. It places the container on a scale, fills it to a target weight, and then stops.

This is the most accurate filling method available. It completely eliminates inaccuracies caused by temperature changes, air bubbles, or variations in honey density.

Choosing the Right Level of Automation

Beyond the filling mechanism, machines are categorized by their level of automation, which dictates production capacity and labor requirements.

Semi-Automatic Machines

These machines require an operator to place containers under the fill heads and initiate each fill cycle, often with a foot pedal.

They are ideal for small businesses, startups, and artisanal producers due to their lower initial cost, smaller footprint, and flexibility for handling various container sizes.

Fully Automatic Machines

These systems are integrated into a larger production line with a conveyor that automatically moves containers through the filling, capping, and labeling stations.

They are designed for large-scale commercial operations where high throughput and minimal labor intervention are critical. The initial investment is significantly higher.

Understanding the Trade-offs

Selecting the right machine requires acknowledging the inherent compromises between different technologies.

Accuracy vs. Speed

Net weigh and piston fillers offer the highest accuracy but may have a slower fill cycle. Pump and gravity fillers typically prioritize speed and throughput, which can sometimes come at the expense of pinpoint accuracy.

Viscosity is Everything

Honey's thickness is the single most important factor. Unheated, highly viscous honey is difficult for gravity fillers to handle but is perfectly suited for piston and pump fillers. Heating your honey can reduce its viscosity, opening up more machine options but adding a step to your process.

Container Type Matters

If you use clear glass jars and want a perfectly uniform appearance on the shelf, an overflow filler is the best choice. For opaque containers or when selling by weight, a piston or net weigh filler provides the necessary volumetric or weight accuracy.

Making the Right Choice for Your Operation

Match the machine's capabilities directly to your primary business goal.

- If your primary focus is artisanal quality and flexibility for small batches: A semi-automatic piston or net weigh filler provides the best combination of accuracy and control.

- If your primary focus is high-volume commercial bottling: A fully automatic rotary pump or multi-head piston filler is necessary to meet speed and efficiency demands.

- If your primary focus is premium retail presentation in clear jars: An overflow filler will ensure every container has a flawless, consistent fill level.

- If your primary focus is creating single-serving packets: A specialized form-fill-seal machine for honey sticks or sachets is the only practical solution.

Ultimately, choosing the right equipment is a strategic investment in the efficiency and quality of your production.

Summary Table:

| Filling Mechanism | Best For | Key Characteristic |

|---|---|---|

| Piston Filler | High-viscosity honey | Volumetric filling; excellent accuracy |

| Pump Filler | High-speed production | Versatile; handles various viscosities |

| Gravity Filler | Lower-viscosity (heated) honey | Simple, cost-effective |

| Overflow Filler | Consistent fill level in clear jars | Cosmetic perfection; level-based |

| Net Weigh Filler | Ultimate accuracy | Weight-based; unaffected by density changes |

Ready to Optimize Your Honey Bottling Line?

Choosing the right filling machine is a critical investment in your operation's efficiency and product quality. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the robust, reliable machinery needed for high-volume production.

We provide wholesale-focused solutions, from semi-automatic piston fillers for artisanal batches to fully automatic rotary systems for large-scale bottling. Let our expertise guide you to the perfect equipment that balances accuracy, speed, and cost for your specific honey.

Contact HONESTBEE today for a personalized consultation and discover how our beekeeping supplies and equipment can streamline your workflow.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What role do professional automated filling and packaging machines play in honey processing? Boost Efficiency & Value

- What are the causes of overheating in honey stick machines? Prevent Downtime with Proper Maintenance

- What is the purpose of the cutter in a honey stick machine? The Key to Perfect, Single-Serve Packaging

- How do honey-filling machines contribute to the commercialization of honey produced by stingless bees? Scale Your Brand

- How can Arrhenius model parameters improve honey filling? Optimize Precision in Industrial Honey Machinery

- What is a VFFS liquid packaging machine and how is it used for honey? Optimize Your High-Speed Sachet Production

- What is the purpose of a Weighing Filling Machine? Ensure Precision and Profitability

- How do high-precision honey filling machines handle stingless honey? Scale Your Commercial Packaging with Precision