In packaging automation, the primary use of a VFFS machine is for efficiently bagging free-flowing and simple products like snacks, coffee, or powders into smaller pouches. In contrast, an HFFS machine is typically used for products that are fragile, oddly shaped, sticky, or require careful placement, often in larger or more complex packaging formats. The choice is dictated by the product itself and the desired final package.

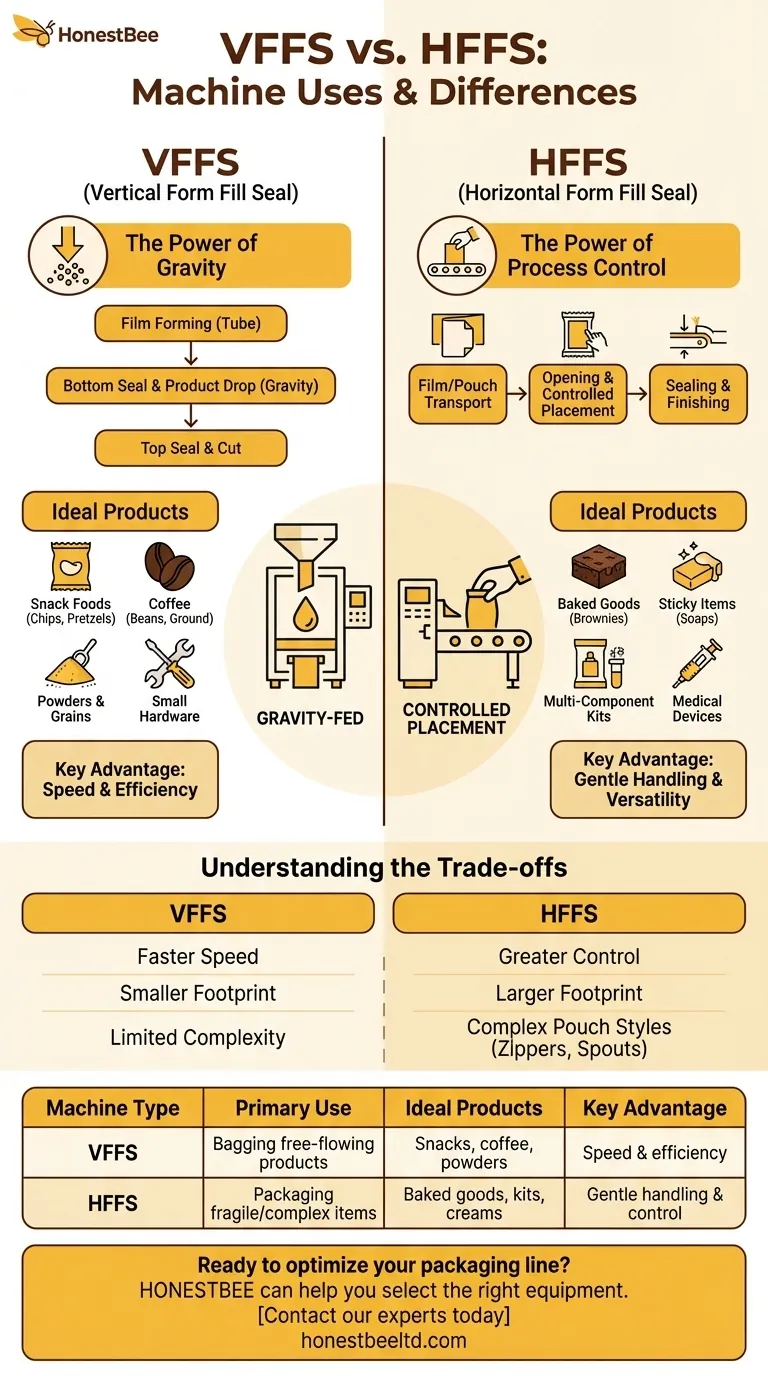

The decision between Vertical Form Fill Seal (VFFS) and Horizontal Form Fill Seal (HFFS) is not just about bag size. The fundamental difference lies in the machine's orientation, which determines how it handles your product: VFFS uses gravity for speed with simple items, while HFFS offers precise control for complex or delicate products.

The Fundamental Difference: Gravity vs. Control

The orientation of the machine—vertical or horizontal—is the single most important factor. This mechanical difference dictates which products are best suited for each system and what kind of packaging can be produced.

How VFFS Machines Work: The Power of Gravity

A Vertical Form Fill Seal machine operates on a simple, effective principle. A roll of film is formed into a tube, sealed on the bottom, and then the product is dropped from a filler or weigher directly into the bag from above.

This process leverages gravity, making it exceptionally fast and efficient for products that can withstand a drop and flow easily. This is why VFFS systems have a compact, vertical footprint, saving valuable floor space.

How HFFS Machines Work: The Power of Process Control

A Horizontal Form Fill Seal machine operates along a linear, horizontal plane. The process involves moving film or pre-made pouches along a conveyor, where they are opened, filled, and sealed in stages.

This horizontal motion allows for much greater control over product handling. Instead of being dropped, products can be gently placed, slid, or arranged inside the pouch, making it ideal for items that are fragile, sticky, or need specific orientation.

Matching the Machine to Your Product

Your product's physical characteristics are the ultimate guide. A mismatch between product and machine type leads to inefficiency, product damage, and poor-quality seals.

Ideal Products for VFFS

VFFS excels with free-flowing products that are uniform and durable. Its speed and efficiency are maximized when gravity does most of the work.

Common examples include snack foods (chips, pretzels), coffee (beans or ground), sugar, grains, powders, and some small, loose hardware.

Ideal Products for HFFS

HFFS is the solution for products that are fragile, sticky, or hard to handle. Its controlled process protects product integrity.

This includes single solid items like brownies or soap bars, medical devices, kits with multiple components, and viscous liquids or creams that do not flow easily.

Understanding the Trade-offs

Neither machine is universally superior; they are engineered for different tasks. Understanding their inherent limitations is key to making a sound investment.

Speed and Footprint

For simple, high-volume bagging of granular products, VFFS is typically faster and requires less floor space due to its vertical design.

HFFS lines are generally longer and may have a slower cycle time per bag, as the process often involves more complex product handling and sealing steps.

Product Handling and Versatility

HFFS offers unmatched versatility in product handling. It can manage multi-component kits, single solid items, and difficult-to-move substances far more effectively than a gravity-fed VFFS system.

While some VFFS machines can be adapted for more complex fills, they are fundamentally optimized for products that flow easily.

Package Complexity

HFFS machines are often better suited for producing more complex pouch styles, such as stand-up pouches with re-closable zippers or fitments like spouts.

The horizontal orientation provides more stability and easier access to the pouch opening, simplifying the integration of these value-added features during the packaging process.

Making the Right Choice for Your Product

To select the correct system, analyze your product and packaging goals first. The machine is a tool designed to serve that specific application.

- If your primary focus is high-speed bagging of free-flowing products (powders, grains, snacks): VFFS is the most efficient and cost-effective solution.

- If your primary focus is packaging fragile, sticky, or multi-component items (baked goods, kits, creams): HFFS provides the necessary control and gentle handling to protect product integrity.

- If your primary focus is creating complex pouches with features like zippers or spouts: HFFS technology is generally better suited for these advanced formats.

Understanding this core distinction between vertical gravity and horizontal control empowers you to select the right technology for your specific packaging needs.

Summary Table:

| Machine Type | Primary Use | Ideal Products | Key Advantage |

|---|---|---|---|

| VFFS | Bagging free-flowing products | Snacks, coffee, powders, grains | Speed and efficiency via gravity |

| HFFS | Packaging fragile or complex items | Baked goods, kits, creams, medical devices | Gentle handling and process control |

Ready to optimize your packaging line?

As a leading supplier to commercial apiaries and distributors, HONESTBEE understands the precision and reliability required for high-volume operations. We can help you select the right VFFS or HFFS packaging equipment to maximize your efficiency and protect your product quality.

Contact our experts today to discuss your specific needs and discover the best packaging solutions for your business.

Visual Guide

Related Products

- Professional Durable Customizable Blister Packing Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Fully Automatic Honey Filling Packaging Machine for Processing Line

People Also Ask

- How do I choose a packing machine? A Guide to Strategic Investment and Seamless Integration

- What is the working principle of bottle packing machine? Achieve Efficient, Automated Filling

- Why is the selection of professional packaging tools and materials critical in the honey supply chain? Protect Your Brand

- What is the importance of versatility and adaptability in a honey packaging machine? Future-Proof Your Production

- What is the purpose of using modified sealing caps and industrial tape in bridging propagation? Boost Hive Acceptance