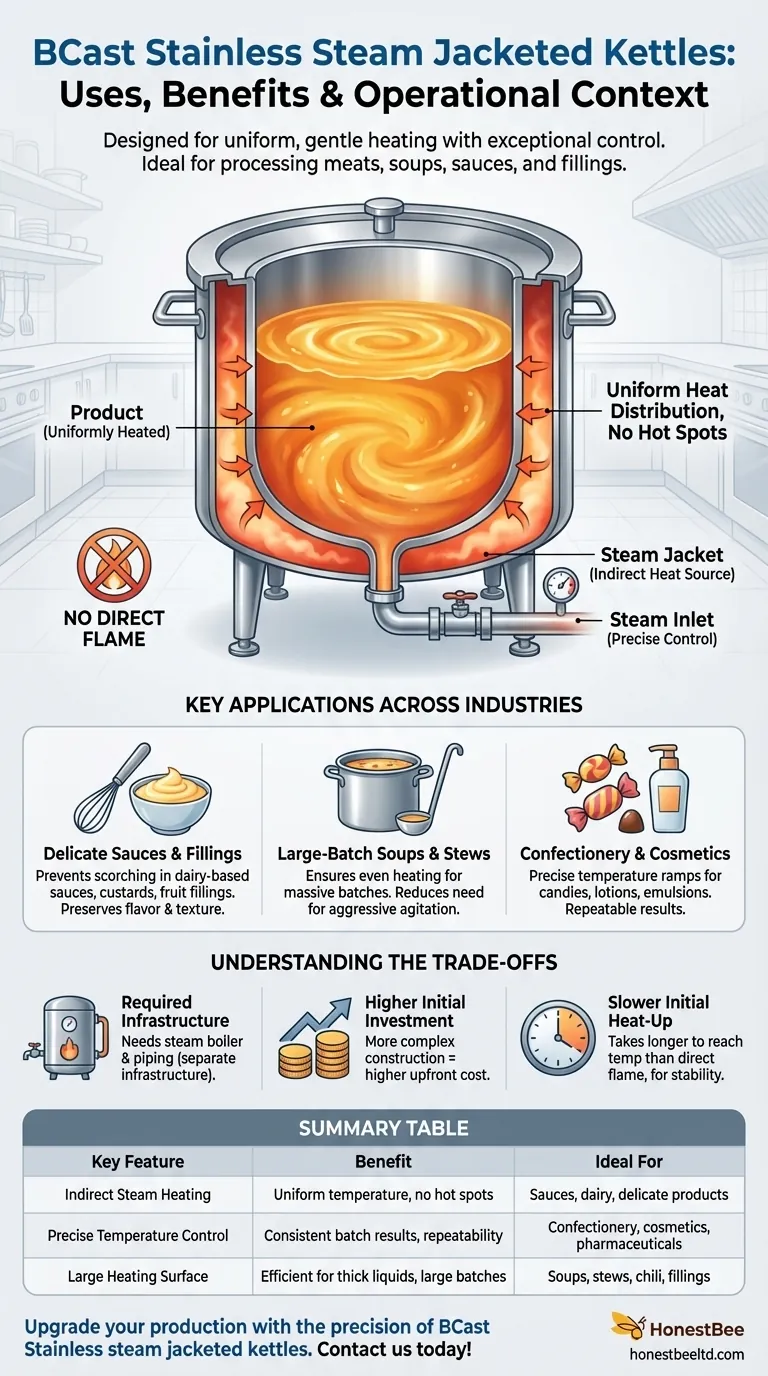

At their core, BCast Stainless steam jacketed kettles are designed for cooking, mixing, and heating a wide variety of products with exceptional control. They are most commonly used for processing foods like meats, soups, sauces, and fillings where uniform temperature and gentle heating are critical to the final product's quality.

The true value of a steam jacketed kettle isn't just what it can cook, but how it cooks. Its versatility stems from using indirect steam heat, which provides uniform temperature distribution and precise control, preventing scorching and ensuring product consistency.

How Steam Jacketed Kettles Achieve Superior Control

The design of a steam jacketed kettle is the key to its performance. It's not simply a large pot; it's a sophisticated piece of equipment engineered for thermal efficiency and control.

The Principle of Indirect Heating

A steam jacketed kettle is essentially a kettle within a kettle. The space between the inner wall (which holds the product) and the outer wall forms the "jacket."

Pressurized steam is fed into this jacket, transferring its thermal energy to the inner wall. The product is heated by this wall, never by a direct flame or heating element.

Uniform Heat Distribution

This indirect method heats the entire surface of the inner kettle simultaneously and evenly. This completely eliminates the "hot spots" found at the bottom of direct-fired pots, which are the primary cause of scorching and burning.

Precise Temperature Control

The temperature of steam is directly related to its pressure. By regulating the steam pressure entering the jacket, you can achieve incredibly precise and stable temperatures inside the kettle. This level of control is essential for delicate products and repeatable batch results.

Key Applications Across Industries

The combination of gentle, even heating and precise control makes these kettles a cornerstone in several industries beyond just general food processing.

For Delicate Sauces and Fillings

Dairy-based sauces, custards, and fruit fillings are highly susceptible to scorching. The uniform heat of a jacketed kettle allows these products to be cooked thoroughly without burning, preserving their intended flavor and texture.

For Large-Batch Soups and Stews

In large-scale production, ensuring a massive batch of soup or chili is heated evenly is a significant challenge. Jacketed kettles solve this by providing a large, consistent heating surface, reducing the need for constant, aggressive agitation.

For Confectionery and Cosmetics

Industries creating candies, lotions, or emulsions rely on precise temperature ramps and holds to achieve the correct chemical structure and consistency. A steam jacketed kettle provides the repeatable thermal control necessary for these sensitive processes.

Understanding the Trade-offs

While highly effective, steam jacketed kettles are a specific tool for a specific job, and it's important to understand their operational context.

Required Infrastructure

The most significant consideration is the need for a steam source. These kettles require a boiler to generate the necessary steam, which represents a separate and significant piece of infrastructure if not already present in a facility.

Higher Initial Investment

Compared to a simple direct-fire kettle, a steam jacketed system has a higher upfront cost due to its more complex construction and the need for associated steam-handling components like traps and valves.

Slower Initial Heat-Up

While the cooking process is highly efficient, bringing the large thermal mass of the kettle and its contents up to temperature can take longer than with a direct flame. However, this is a trade-off for superior temperature stability and safety.

Making the Right Choice for Your Process

Selecting the right equipment depends entirely on your product and production goals.

- If your primary focus is product consistency and quality for delicate items: A steam jacketed kettle is the ideal choice for preventing scorching in sauces, dairy, or confections.

- If your primary focus is large-scale, efficient production of liquids: The uniform heating of a jacketed kettle ensures even cooking and reduces labor for thick products like soups and stews.

- If your primary focus is process repeatability: The precise temperature control offered by steam is unmatched for applications in brewing, pharmaceuticals, or any field requiring exact thermal profiles.

Ultimately, choosing a steam jacketed kettle is an investment in control, consistency, and the quality of your final product.

Summary Table:

| Key Feature | Benefit | Ideal For |

|---|---|---|

| Indirect Steam Heating | Uniform temperature, no hot spots | Sauces, dairy, delicate products |

| Precise Temperature Control | Consistent batch results, repeatability | Confectionery, cosmetics, pharmaceuticals |

| Large Heating Surface | Efficient for thick liquids, large batches | Soups, stews, chili, fillings |

Upgrade your production with the precision of BCast Stainless steam jacketed kettles.

For commercial apiaries and beekeeping equipment distributors, consistent, high-quality product processing is key to your success. Whether you're producing honey-based sauces, infusions, or other value-added goods, our kettles deliver the uniform heating and precise temperature control you need to prevent scorching and ensure every batch meets your standards.

We supply durable, efficient beekeeping supplies and equipment through wholesale-focused operations. Let us help you enhance your product quality and operational efficiency.

Contact us today to discuss how our steam jacketed kettles can benefit your process!

Visual Guide

Related Products

- Stainless Steel Honey Press Wax Press with Tank

- HONESTBEE 8 Frame Electric and Manual Three Use Honey Extractor

- Adjustable Stainless Steel Honey Uncapping Fork with Plastic Handle for Beekeeping

- Professional Classic Wood Handle Honey Uncapping Fork

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- How does industrial heating equipment facilitate the decontamination of beekeeping tools? Eliminate Nosema apis Efficiently

- How can granulated honey be returned to its liquid form? Restore Your Honey with Gentle Heat

- How does a jacket cooling system contribute to the thickening process of bee candy concentrate? Master Precise Textures

- What is the function of a heating system for beehives? Accelerate Colony Growth with Ceramic Heat Regulation

- What should be done if stored honey crystallizes? Best Techniques for Restoring Texture Without Losing Quality

- Is it safe to heat crystallized honey? Restore Your Honey's Liquid State Safely

- What is the primary function of Peltier Modules in beehives? Boost Winter Colony Survival with Solid-State Heating

- What is the function of industrial-grade electric heating aluminum plates? Precision Beehive Thermal Simulation Guide