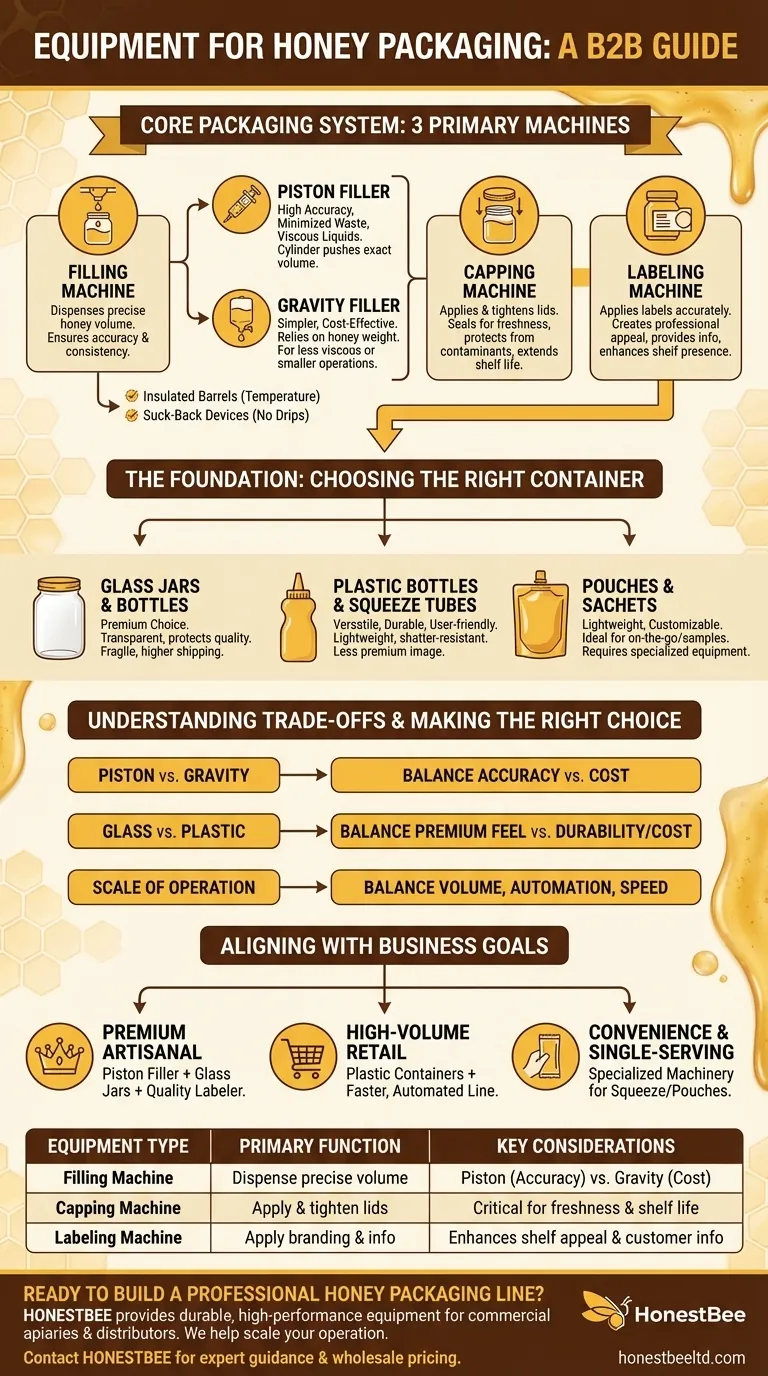

At its core, packaging honey for distribution requires a system of three primary machines. This line includes a filling machine to dispense the honey, a capping machine to seal the container, and a labeling machine to apply branding and product information.

The choice of honey packaging equipment is not a one-size-fits-all decision. It is a strategic process dictated by your choice of container, your scale of operation, and the final product presentation you wish to achieve.

The Core Components of a Honey Packaging Line

A professional honey packaging operation moves from filling to sealing to labeling. Each stage relies on specialized equipment designed to handle honey's unique properties.

The Filling Machine: Ensuring Accuracy

The filling machine is responsible for dispensing a precise, consistent amount of honey into each container. This is the heart of the packaging line.

The two most common types are piston fillers and gravity fillers. Piston fillers use a cylinder mechanism to pull in and then push out an exact volume of honey, ensuring high accuracy. Gravity fillers rely on the weight of the honey itself to fill containers positioned below.

Some honey fillers also include features like double-layer insulated barrels to maintain honey's temperature and purity, as well as suck-back devices to prevent drips and leakage after a fill.

The Capping Machine: Sealing for Freshness

Once filled, the container moves to a capping machine. This equipment automatically applies and tightens the lid onto the jar or bottle.

Proper sealing is critical for protecting the honey from contaminants, preserving its freshness, and ensuring a long shelf life.

The Labeling Machine: Creating Shelf Appeal

The final step is labeling. A labeling machine accurately and consistently applies labels to the containers.

This ensures a professional appearance, provides essential product information to the customer, and significantly enhances your product's appeal on the retail shelf.

The Foundation: Choosing the Right Container

Before you select any machinery, you must first decide on your packaging. The type of container you choose directly influences the equipment you will need.

Glass Jars and Bottles

Glass is often considered the premium choice for honey packaging. It is transparent, allowing customers to see the product clearly, and it effectively protects the honey's quality.

Plastic Bottles and Squeeze Tubes

Plastic containers are valued for their versatility and durability. Squeeze bottles, in particular, offer a user-friendly dispensing method that many consumers prefer.

Pouches and Sachets

Flexible pouches and single-serving sachets are lightweight and highly customizable. This format is ideal for on-the-go use or for creating sample sizes. These require different filling and sealing machines than traditional bottles.

Understanding the Trade-offs

Selecting the right equipment involves balancing cost, efficiency, and the final product's quality.

Piston vs. Gravity Fillers

A piston filler offers superior accuracy, which is crucial for minimizing product waste and maintaining consistency. A gravity filler may be a simpler, more cost-effective option, especially for less viscous liquids or smaller-scale operations.

Container Material Impact

Glass provides a high-end feel but is heavier and more fragile, leading to higher shipping costs. Plastic is lightweight and shatter-resistant but may not convey the same premium image as glass.

Scale of Operation

The equipment suitable for a small, local beekeeper is vastly different from that needed for a large-scale industrial operation. Your production volume will be the primary factor determining the speed, automation level, and cost of the machinery you require.

Making the Right Choice for Your Goal

Your packaging decisions should align directly with your business strategy and target market.

- If your primary focus is a premium, artisanal product: A piston filler for accuracy paired with classic glass jars and a high-quality labeler will best convey quality.

- If your primary focus is high-volume retail distribution: Lightweight plastic containers and a faster, more automated filling and capping line will optimize for efficiency and lower costs.

- If your primary focus is convenience and single-serving products: Specialized machinery for filling and sealing squeeze bottles or flexible pouches is the correct path.

Ultimately, investing in the right packaging system ensures your honey is presented professionally, preserved effectively, and delivered efficiently to your customers.

Summary Table:

| Equipment Type | Primary Function | Key Considerations |

|---|---|---|

| Filling Machine | Dispenses precise honey volume | Piston (high accuracy) vs. Gravity (cost-effective) |

| Capping Machine | Applies and tightens container lids | Critical for product freshness and shelf life |

| Labeling Machine | Applies branding and product info | Enhances shelf appeal and provides customer information |

Ready to build a professional honey packaging line?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-performance equipment you need to scale your operation. We help you select the right filling, capping, and labeling machinery to match your specific containers, production volume, and business goals.

Contact HONESTBEE today for expert guidance and wholesale pricing on beekeeping supplies and equipment.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

People Also Ask

- What are the technical advantages of using an automated honey filling machine? Precision for Large-Scale Production

- How do high-precision automated honey-filling machines contribute to commercial value? Enhance Your Honey Brand Assets

- Why are automated honey filling machines essential? Transform Your Honey Production for Global Commercial Success

- What are the main processes of a sachet filling and packing machine? Streamline Your Packaging Line

- What types of honey stick machines are available based on the style of the stick pack? Choose the Perfect Packaging Format

- What advantages does industrial honey filling and bottling equipment offer? Boost Efficiency and Product Purity

- What are the advantages of using high-precision honey-filling machines for Tetragonula iridipennis honey?

- Why are automatic honey-filling machines essential for meeting strict quality certifications? | Secure Your PDO/PGI Label