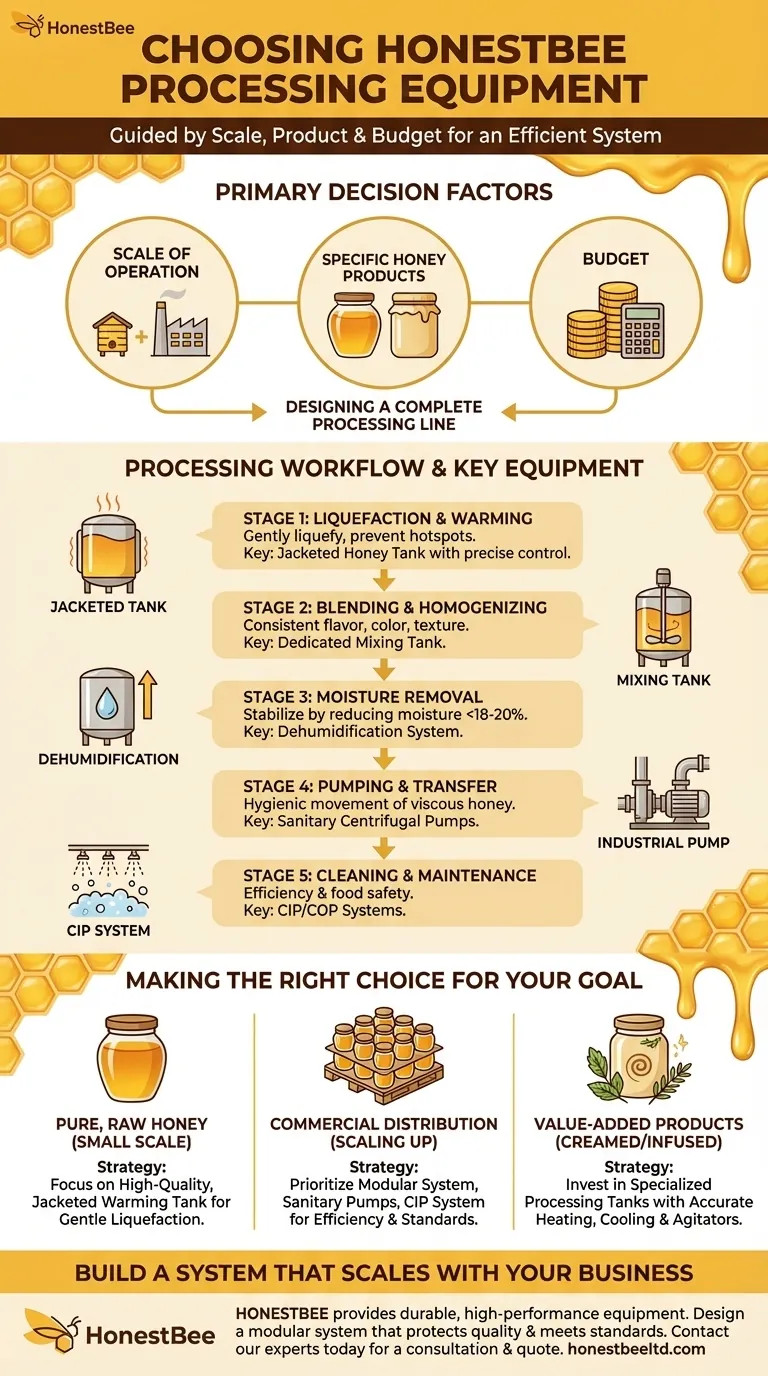

When choosing honey processing equipment, your decision must be guided by three primary factors: the scale of your operation, the specific honey products you intend to create, and your budget. Selecting the right machinery is not just about a single purchase; it’s about designing an efficient system that protects the quality of your honey from extraction to the final package.

The most critical mistake is buying equipment in isolation. Instead, you must think of your setup as a complete processing line, where each component—from tanks to pumps—works together to match your specific production goals and scale.

Matching Equipment to Your Processing Workflow

A successful honey operation depends on a logical flow. Each piece of equipment serves a distinct purpose in transforming raw honey from the comb into a stable, marketable product.

Stage 1: Liquefaction and Warming

Most raw honey will crystallize and must be gently liquefied before it can be filtered or bottled. This is the most common and critical processing step.

The primary tool here is a jacketed honey tank. These tanks use a surrounding jacket of circulating hot water to provide gentle, even heat, preventing hotspots that can scorch the honey and destroy its delicate enzymes and aromas. A central stirrer or agitator ensures uniform temperature throughout the batch.

Stage 2: Blending and Homogenizing

If you plan to create blended honey from different floral sources or make value-added products like infused honey, you need a dedicated mixing tank.

These are often similar to warming tanks but are specifically designed with agitators that can effectively blend ingredients without introducing excess air. This step is crucial for ensuring a consistent flavor, color, and texture in every jar.

Stage 3: Moisture Removal (Dehumidification)

Honey with a moisture content above 18-20% is at risk of fermenting. While proper harvesting is the first line of defense, some processing plants can remove excess moisture.

This is an advanced feature, often found in larger, integrated systems. It allows you to stabilize honey that might otherwise be unsuitable for long-term storage, expanding your usable supply.

Stage 4: Pumping and Transfer

Moving honey, which is highly viscous, requires specialized pumps. Using the wrong pump can damage the honey or the equipment.

Look for sanitary centrifugal or industrial pumps designed for food-grade products. These are paired with a system of sanitary valves and fittings to move honey between tanks, filters, and bottling lines hygienically and efficiently.

Stage 5: Cleaning and Maintenance

Efficiency is not just about processing; it's also about cleanup. The design of your equipment directly impacts your labor costs and food safety.

For smaller operations, equipment that is easy to disassemble for manual washing is sufficient. Larger operations should consider Clean-in-Place (CIP) or Clean-out-of-Place (COP) tanks, which automate the cleaning cycle, saving significant time and ensuring consistent sanitation.

Understanding the Trade-offs

Choosing equipment involves balancing cost, functionality, and quality. A decision that seems economical upfront can lead to hidden costs later.

Integrated Systems vs. Modular Components

An all-in-one processing plant that handles warming, mixing, and moisture removal seems convenient. However, it offers less flexibility if you decide to change or expand your product line.

A modular approach, using separate tanks and pumps, allows you to scale up gradually. You can start with a single warming tank and add a dedicated mixing tank later. This requires more planning but offers greater long-term adaptability.

The True Cost of "Low-Cost" Equipment

Equipment with a low initial price may lack key features that protect honey quality. Poor insulation or inadequate temperature control can lead to higher energy bills and, more importantly, a damaged product.

Furthermore, equipment that is difficult to clean poses a food safety risk and increases labor costs. A hygienic design with smooth welds and easy access is a non-negotiable feature, not a luxury.

Over-processing vs. Under-processing

More is not always better. Aggressive heating or mixing can darken honey, drive off its volatile aromatics, and destroy beneficial enzymes. Your equipment must give you precise control.

Conversely, under-processing can lead to premature crystallization or fermentation. The goal is to apply the minimum necessary processing to achieve a stable, high-quality product, and your equipment must be capable of that nuance.

Making the Right Choice for Your Goal

Your equipment strategy should be a direct reflection of your business objectives.

- If your primary focus is selling pure, raw liquid honey at a small scale: Your most important investment is a high-quality, jacketed warming tank with precise temperature control for gentle liquefaction.

- If your primary focus is scaling up for commercial distribution: Prioritize a modular system with dedicated tanks, sanitary pumps, and valves. A Clean-in-Place (CIP) system will be critical for achieving efficiency and meeting food safety standards.

- If your primary focus is creating value-added products like creamed or infused honey: Invest in processing tanks with specialized agitators and highly accurate heating and cooling systems to manage crystallization and blending.

Ultimately, choosing the right equipment is an investment in the quality, consistency, and efficiency of your entire operation.

Summary Table:

| Processing Stage | Key Equipment | Primary Function |

|---|---|---|

| Liquefaction & Warming | Jacketed Honey Tank | Gentle, even heating to liquefy honey without damage. |

| Blending & Homogenizing | Mixing Tank | Consistent blending of ingredients for value-added products. |

| Moisture Removal | Dehumidification System | Stabilizes honey by reducing moisture content to prevent fermentation. |

| Pumping & Transfer | Sanitary Centrifugal Pumps | Hygienic and efficient movement of viscous honey. |

| Cleaning & Maintenance | CIP/COP Systems | Automated cleaning for efficiency and food safety compliance. |

Ready to build a honey processing system that scales with your business?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-performance equipment you need. We help you design a modular system that protects honey quality, improves efficiency, and meets food safety standards—whether you're focused on raw honey, value-added products, or large-scale distribution.

Contact our experts today for a customized equipment consultation and quote.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Professional Thermostatic Conical Honey Melter

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What machines are needed in beekeeping besides basic tools? Scale Your Honey Harvest Efficiently

- What is a fun and easy alternative to using a honey extractor for harvesting honey? Try the Crush and Strain Method

- How do you manually extract honey? Choose the Best Method for Your Hive

- What is the principal idea in harvesting honey? A 3-Step Guide to a Responsible Harvest

- What size honey extractor do I need? Match Frame Capacity to Your Hives for Maximum Efficiency