When choosing between hive materials, beekeepers must weigh the traditional appeal of wood against the significant performance benefits of modern polystyrene. The primary factors to consider are insulation, durability, weight, and long-term maintenance. While wooden hives are a familiar standard, high-density polystyrene offers superior thermal regulation that directly impacts bee health and honey production.

The decision between wood and polystyrene is a choice between tradition and performance. Wooden hives are natural and customizable but demand significant physical effort and maintenance. Polystyrene hives prioritize the colony's well-being and the beekeeper's efficiency through superior insulation and a lightweight, durable design.

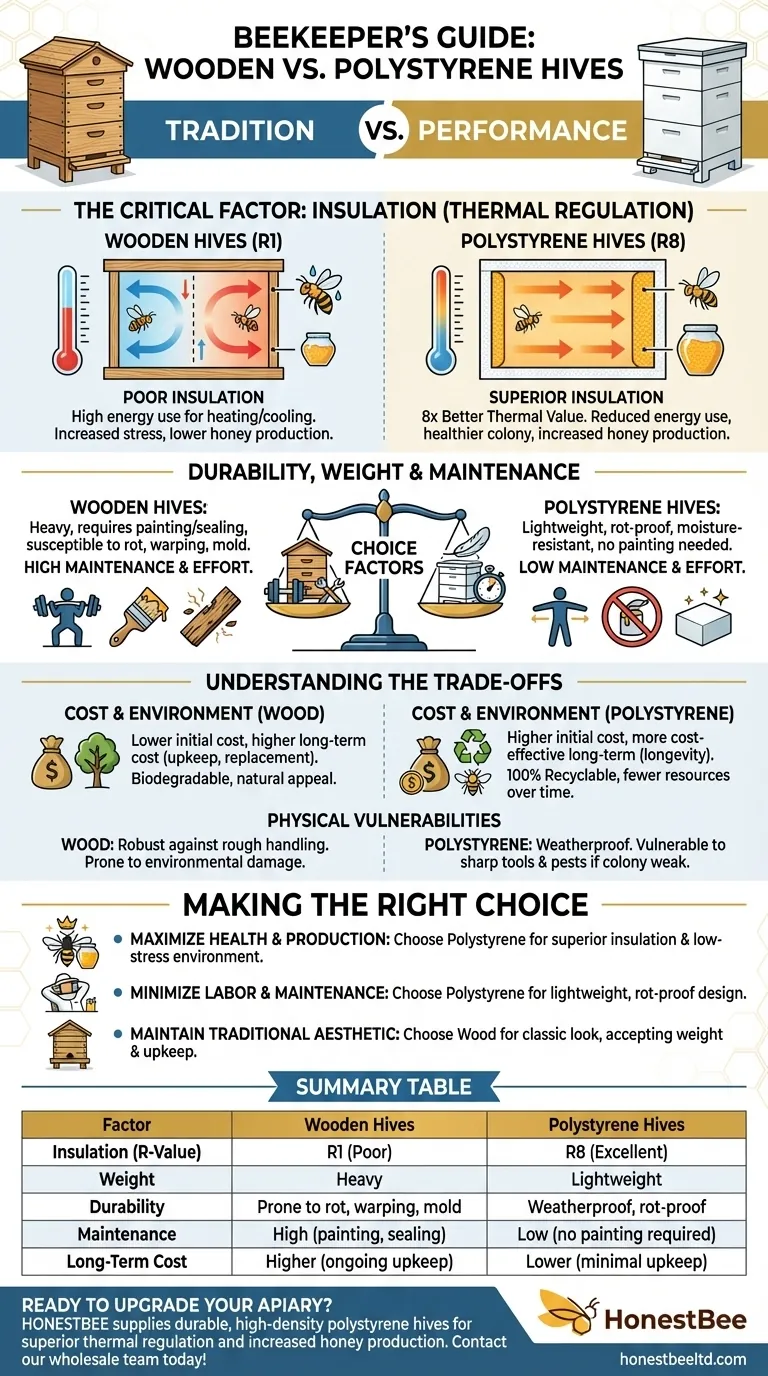

The Critical Factor: Hive Insulation

A hive's ability to regulate temperature is the single most important factor for colony health and productivity. Bees must expend enormous energy to heat the hive in winter and cool it in summer.

Superior Thermal Performance of Polystyrene

Polystyrene hives provide vastly better insulation than wood. A standard high-density polystyrene hive has an insulation value of around R8, whereas a wooden hive of the same thickness is only about R1.

This difference means the colony uses far less energy and consumes fewer winter stores to maintain its cluster temperature. In the summer, the insulation protects the hive from overheating, reducing the need for bees to perform fanning and water-foraging behaviors.

The Direct Impact on Bee Health

Stable internal temperatures reduce stress on the colony. This leads to a healthier queen and a more robust brood, as the bees can maintain the ideal temperature for larval development with less effort.

The Connection to Honey Production

When bees expend less energy on temperature control, they can dedicate more energy to foraging for nectar. This efficiency gain often translates directly into increased honey production compared to colonies housed in less-insulated wooden hives.

Durability, Weight, and Maintenance

Beyond insulation, the physical properties of the hive material dictate the beekeeper's workload and the equipment's lifespan.

The Weight and Handling Advantage

Polystyrene hives are significantly lighter than wooden hives, making them much easier to lift, inspect, and transport. This is a crucial consideration for beekeepers with physical limitations or those managing multiple apiaries.

Maintenance Requirements of Wood

Wooden hives require considerable upkeep. They must be assembled, painted or sealed to protect them from the elements, and are susceptible to rot, warping, and mold over time. This requires ongoing labor and cost.

The Longevity of Polystyrene

High-density polystyrene is inert and does not rot or absorb moisture. It requires no painting or chemical treatments, making it a low-maintenance option that can withstand environmental damage for many years.

Understanding the Trade-offs

Choosing a hive material is not just about performance; it's also about cost, environmental impact, and practical realities.

Cost: Initial vs. Long-Term

While a single wooden hive box may have a lower initial purchase price, the total cost of ownership is often higher. When factoring in the need for paint, sealants, and eventual replacement due to weather damage, polystyrene becomes a more cost-effective investment over the hive's lifespan.

Environmental Impact

Wooden hives have a natural appeal and are biodegradable. However, polystyrene is 100% recyclable, and its long service life means fewer resources are consumed over time. Its superior insulation also means the bees consume fewer resources (winter stores) to survive.

Physical Vulnerabilities

Wood is robust and can withstand rough handling and scraping from hive tools. Polystyrene, while durable against weather, can be damaged by careless use of sharp tools or by pests like wax moths if the colony is weak and cannot defend its space.

Making the Right Choice for Your Apiary

Your decision should be guided by your specific goals as a beekeeper.

- If your primary focus is maximizing bee health and honey production: The superior insulation of polystyrene makes it the logical choice for creating a low-stress, highly productive environment.

- If your primary focus is minimizing physical labor and maintenance: The lightweight, rot-proof nature of polystyrene hives will save you significant time and effort.

- If your primary focus is maintaining a traditional aesthetic: Wooden hives are the classic standard, but be prepared for the added demands of weight and ongoing maintenance.

Ultimately, choosing the right hive means aligning your management style with the material that best supports a thriving, healthy colony.

Summary Table:

| Factor | Wooden Hives | Polystyrene Hives |

|---|---|---|

| Insulation (R-Value) | R1 (Poor) | R8 (Excellent) |

| Weight | Heavy | Lightweight |

| Durability | Prone to rot, warping, mold | Weatherproof, rot-proof |

| Maintenance | High (painting, sealing) | Low (no painting required) |

| Long-Term Cost | Higher (ongoing upkeep) | Lower (minimal upkeep) |

Ready to upgrade your apiary with high-performance hives? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, high-density polystyrene hives designed for superior thermal regulation, increased honey production, and reduced maintenance. Let us help you build a more efficient and profitable operation. Contact our wholesale team today to discuss your needs!

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Langstroth Honey Bee Box Hive Boxes for Different Depths

- Australian Langstroth Beehive Boxes for Beekeeping Wholesales

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- How does the orientation of the hive sides benefit comb construction? Ensure Straight, Movable Combs for Easier Hive Management

- What are the primary technical advantages of using Langstroth beehives? Maximize Your Commercial Honey Yield

- Should a beginner try a different type of hive? Start with a Langstroth for a solid foundation.

- What are the standard widths available for Langstroth hive boxes? Choose the Best Size for Your Apiary

- What are the advantages of standard Langstroth movable-frame beehives? Boost Honey Yields by 1.8x