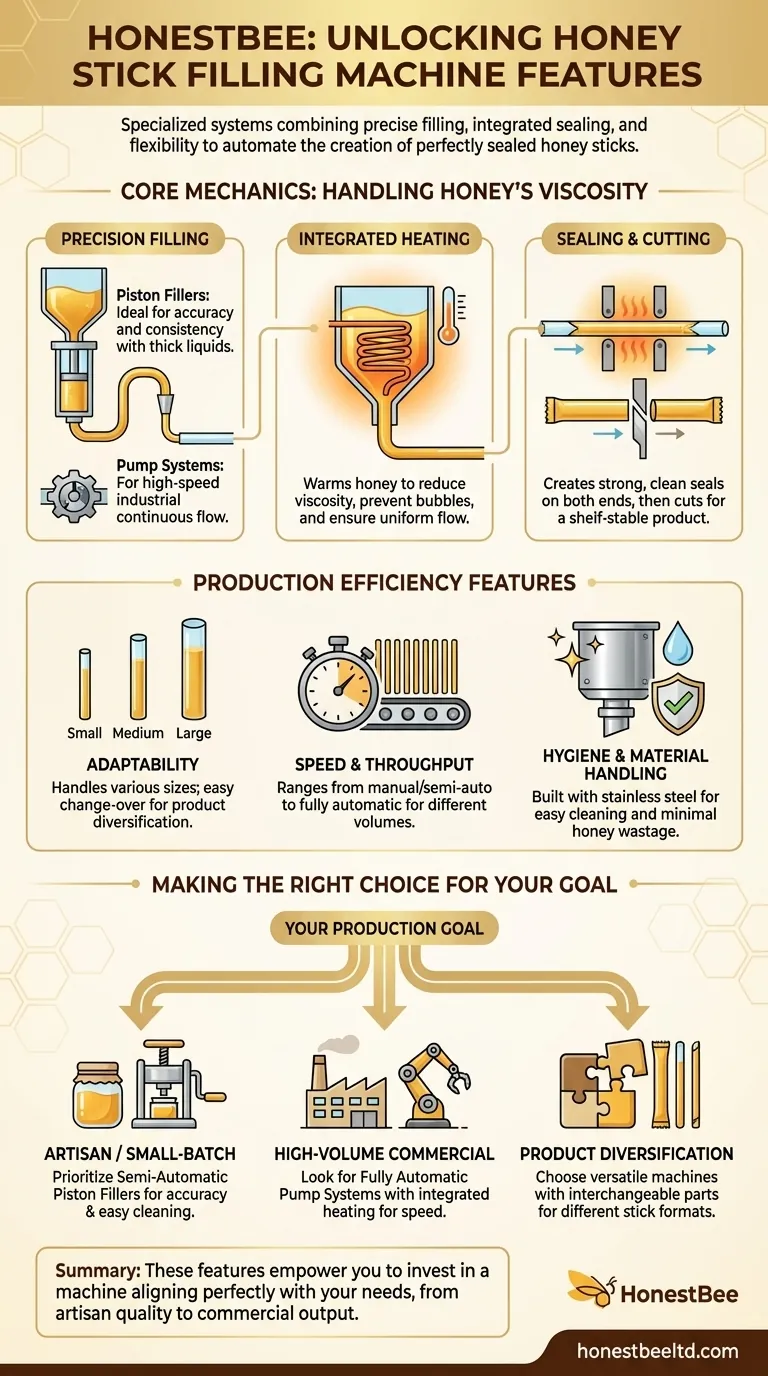

At their core, honey stick filling machines are engineered systems that offer three primary features: a precise filling mechanism to handle honey's viscosity, an integrated sealing function to create the finished stick, and the flexibility to accommodate various stick sizes and production volumes. These features work together to automate the creation of clean, consistent, and perfectly sealed honey sticks with minimal waste.

The most critical takeaway is that a honey stick machine is more than just a filler. It is a specialized system designed to overcome the specific challenges of working with honey—its thickness and stickiness—by combining precise dispensing, often with heat, and a reliable sealing process into a single, efficient workflow.

The Core Mechanics: How Honey is Handled

To understand these machines, you must first understand how they are designed to manage honey's unique physical properties. The process is not just about dispensing a liquid; it's about controlling a thick, viscous substance.

Precision Filling Mechanisms

The heart of any machine is its filling technology. Piston fillers are the most common and effective choice for honey. This mechanism uses a cylinder to pull in a precise volume of honey and then dispense it accurately into the straw, making it ideal for thick liquids where consistency is key.

Other methods exist, like gravity fillers, which are better suited for thinner liquids. While they can be adapted for honey (often with heating), they may offer less precision than a piston system. For very high-speed, industrial operations, pump-based systems regulate a continuous flow of honey.

Integrated Heating Systems

Many high-quality machines include an optional or integrated heating element in the hopper where the honey is held. Gently warming the honey reduces its viscosity, making it flow more smoothly and consistently.

This feature is critical for preventing air bubbles in the sticks and ensuring the filling mechanism operates without clogs or strain, leading to a more uniform and professional-looking final product.

Sealing and Cutting

A honey stick is useless if it is not sealed properly. After filling, the machine must create a strong, clean seal on both ends of the straw. This is typically done using heat and pressure. The machine then cuts the sealed portion to create the individual stick, ensuring a mess-free and shelf-stable product.

Features for Production Efficiency

Beyond the core mechanics, certain features determine the machine's speed, versatility, and suitability for your specific business scale.

Adaptability to Stick Sizes

The ability to handle different stick lengths and diameters is a key feature. This versatility allows you to offer various product sizes or flavors without needing to purchase an entirely new machine. Look for machines that offer easy-to-change parts for different stick formats.

Speed and Throughput

Machines range from manual or semi-automatic models for small-batch producers to fully automatic systems for large-scale commercial operations. Speed is dictated by the filling mechanism and the level of automation, directly impacting your production capacity.

Hygiene and Material Handling

Because honey is a food product, these machines are built with hygiene in mind. Features include the use of food-grade stainless steel and designs that are easy to disassemble for cleaning. They are also engineered for minimal wastage, ensuring that the valuable honey ends up in the stick, not on the machine.

Understanding the Trade-offs

Choosing a machine involves balancing capability, speed, and cost. There is no single "best" machine, only the one that is right for your goals.

Piston vs. Pump Fillers

A piston filler offers superior accuracy and control, which is perfect for ensuring every stick has the exact same amount of honey. A pump filler prioritizes speed and is built for high-volume throughput, making it the choice for large industrial lines where small variations in fill volume are acceptable.

Automation Level and Labor

A semi-automatic machine requires an operator to place straws and activate the fill cycle, making it ideal for startups or artisan producers. A fully automatic machine handles the entire process from loading straws to dispensing filled sticks, drastically reducing labor costs but requiring a much larger initial investment.

The Cost of Versatility

A machine that can handle a wide array of stick sizes and fill volumes will inherently be more complex and expensive. If you only plan to produce one standard size of honey stick, a more specialized and potentially less expensive machine may be a more efficient investment.

Making the Right Choice for Your Goal

Selecting the right features depends entirely on your production scale and business strategy.

- If your primary focus is small-batch or artisan production: Prioritize a semi-automatic piston filler that emphasizes fill accuracy and is easy to clean.

- If your primary focus is high-volume commercial output: Look for a fully automatic machine, likely with a pump system and integrated heating, to maximize speed and minimize labor.

- If your primary focus is product diversification: Choose a versatile machine with interchangeable parts that can easily adapt to different stick lengths, diameters, and potentially different product viscosities.

Ultimately, understanding these features empowers you to invest in a machine that aligns perfectly with your production needs and business ambitions.

Summary Table:

| Feature | Benefit | Key For |

|---|---|---|

| Precision Piston Filler | Accurate honey volume, minimal waste | Artisan & quality-focused producers |

| Integrated Heating | Reduces viscosity, prevents clogs | Consistent flow, high-volume output |

| Sealing & Cutting | Creates clean, shelf-stable sticks | All producers for product integrity |

| Adjustable Stick Sizes | Versatility for different products | Businesses diversifying offerings |

| Semi-Automatic Operation | Lower cost, operator-controlled | Small-batch & startup operations |

| Fully Automatic Operation | High speed, reduced labor | Large-scale commercial production |

Ready to find the perfect honey stick machine for your apiary or distribution business?

HONESTBEE specializes in supplying commercial apiaries and beekeeping equipment distributors with robust, efficient honey stick filling solutions. Whether you need a semi-automatic machine for artisanal batches or a fully automatic system for high-volume output, we provide the right equipment to boost your productivity and product quality.

Contact HONESTBEE today to discuss your production goals and get a tailored solution!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- How do industrial honey filling machines control metal contamination? Ensuring Pure, Export-Ready Honey Production

- Why are industrial-grade automatic filling machines necessary for the commercial marketing of honey? Scale Your Success

- What is the general working principle of honey filling machines? Master Precision & Automation in Your Apiary

- How do industrial honey filling machines assist honey producers? Unlock Retail Success & Higher Margins

- How do automated honey filling machines improve the efficiency of the honey production chain? Boost Output and Quality

- How do industrial honey filling machines enhance performance? Boost Precision, Hygiene, and Scalability

- How do automatic honey-filling machines facilitate the transition to retail? Professional Solutions for Beekeeping

- What are the benefits of using a phenology-based prediction system? Boost Honey Processing & Filling Efficiency