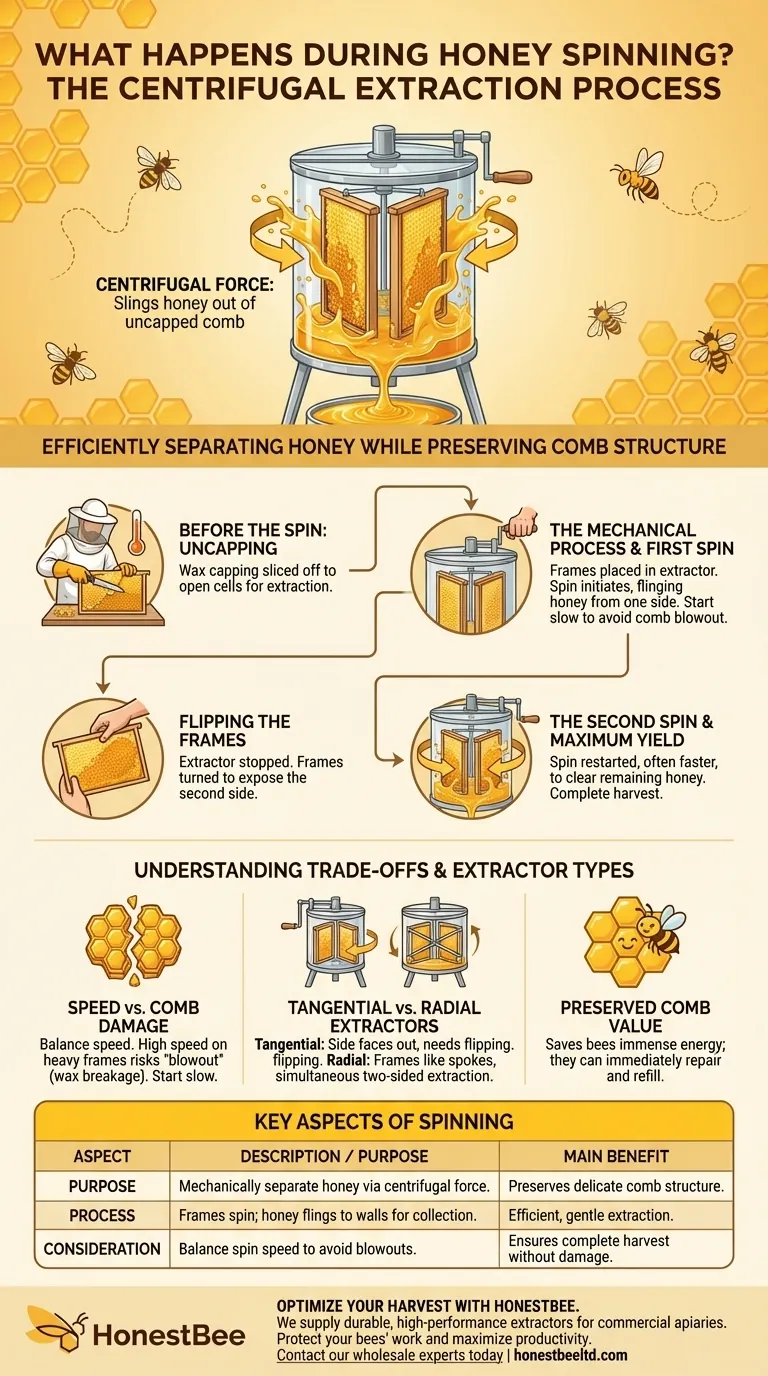

In honey extraction, the spinning process uses centrifugal force to sling liquid honey out of the uncapped wax honeycomb. Beekeepers place the uncapped frames into a machine called an extractor, which spins them at a high speed. This force pushes the honey outward against the inner walls of the extractor, where it drips down to a collection point at the bottom.

The core purpose of spinning, or centrifugation, is to mechanically separate honey from the delicate wax comb. This method is highly efficient and, crucially, preserves the comb's structure, allowing the bees to repair and reuse it.

The Role of Spinning in the Extraction Workflow

Spinning isn't the first or last step in harvesting honey. It sits in the middle of a larger process, acting as the primary mechanism for separating the honey from its comb.

Before the Spin: Uncapping the Cells

For honey to be extracted, its storage container must be opened. Bees seal each cell of honey with a thin layer of beeswax, known as a "capping." Before the frames can be spun, this wax capping must be carefully sliced off with a special knife or tool.

The Principle: Centrifugal Force at Work

The extractor works on the same principle as a salad spinner or the spin cycle of a washing machine. As the frames spin rapidly, the liquid honey is flung outward, away from the center of rotation. Because the honey is heavier than the comb, it easily separates and travels to the extractor's wall.

The Mechanical Process

Once uncapped, frames are placed vertically into a metal mesh basket inside the extractor. The beekeeper closes the lid and begins to crank a handle (or turn on a motor), initiating the spin. The honey flies out of the cells, hits the inner wall, and flows down to the bottom of the tank.

A Two-Sided Process for Maximum Yield

Honeycomb is a two-sided structure, and a single spin can only clear out the cells facing outward. To get a complete harvest, the process must be done in two stages.

The First Spin

The initial spin extracts honey from one side of the comb. It's often done at a lower speed to begin with, preventing the sheer weight of the honey in the opposite side's cells from blowing out the delicate wax structure.

Flipping the Frames

After the first side is reasonably empty, the beekeeper stops the extractor. Each frame is removed, physically turned around, and placed back into the basket so the other side now faces outward.

The Second Spin

The extractor is started again, often at a higher speed now that the frames are lighter. This second spin clears the remaining honey from the comb, completing the extraction for that set of frames.

Understanding the Trade-offs

While effective, the spinning process requires a degree of care to balance speed with the preservation of the comb.

Speed and Comb Damage

The primary risk during extraction is a "blowout," where the force of the spin breaks the delicate wax foundation of the comb. This is most likely to happen on the first spin when the frame is at its heaviest. Starting slowly and gradually increasing speed is critical.

Tangential vs. Radial Extractors

The process described—spinning, flipping, and spinning again—is characteristic of a tangential extractor, where the side of the frame faces outward. Another common type, the radial extractor, places frames like spokes on a wheel. In a radial extractor, force is applied to both sides of the comb simultaneously, often eliminating the need for flipping.

The Value of Preserved Comb

The ultimate goal is to remove the honey while causing minimal damage. A preserved comb saves bees an immense amount of energy and resources, as they do not have to rebuild the wax structure from scratch. They can immediately begin repairing the cells and refilling them with new honey.

Applying This to Your Harvest

The technique you use for spinning will depend on your priorities for the harvest.

- If your primary focus is efficiency: Ensure every honey cell is fully uncapped before spinning, as any remaining wax will trap the honey.

- If your primary focus is preserving your comb: Always start the extractor at a slow speed and ramp up gradually, especially with heavy, full frames.

- If your primary focus is a complete harvest: Remember to spin both sides of the frame, whether by flipping it in a tangential extractor or by ensuring a long enough spin in a radial one.

Ultimately, mastering the spinning process is about balancing speed and care to achieve a clean harvest while protecting the bees' valuable comb for future use.

Summary Table:

| Key Aspect | Description |

|---|---|

| Purpose | Mechanically separate honey from wax comb using centrifugal force. |

| Main Benefit | Preserves the delicate comb structure for bees to repair and reuse. |

| Process | Frames are spun in an extractor, flinging honey out to the walls for collection. |

| Key Consideration | Balance spin speed to avoid comb damage (blowouts) while ensuring a complete harvest. |

Ready to optimize your honey harvest?

Mastering the spinning process is key to a high yield and healthy hives. At HONESTBEE, we supply commercial apiaries and equipment distributors with the durable, high-performance extractors and tools needed for an efficient and gentle extraction.

Let us help you protect your bees' hard work and maximize your operation's productivity.

Contact our wholesale experts today to discuss your beekeeping supply needs!

Visual Guide

Related Products

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Professional Stainless Steel Honey Filtering Machine with Water Bath Heating for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

People Also Ask

- What is the purpose of the settling and filtration process after honey extraction? Master Honey Purity and Market Grade

- What specific issues do filtration and purification equipment address? Ensure Honey Purity and Market Standardization

- What functions do high-precision filtering and moisture control equipment serve in honey refining? Ensure Pure Quality

- Why are stainless steel filters essential during the initial purification phase of honey processing? Ensure Purity

- What is the primary purpose of multi-stage honey filtration? Achieve Visual Clarity and Purity Without Compromise