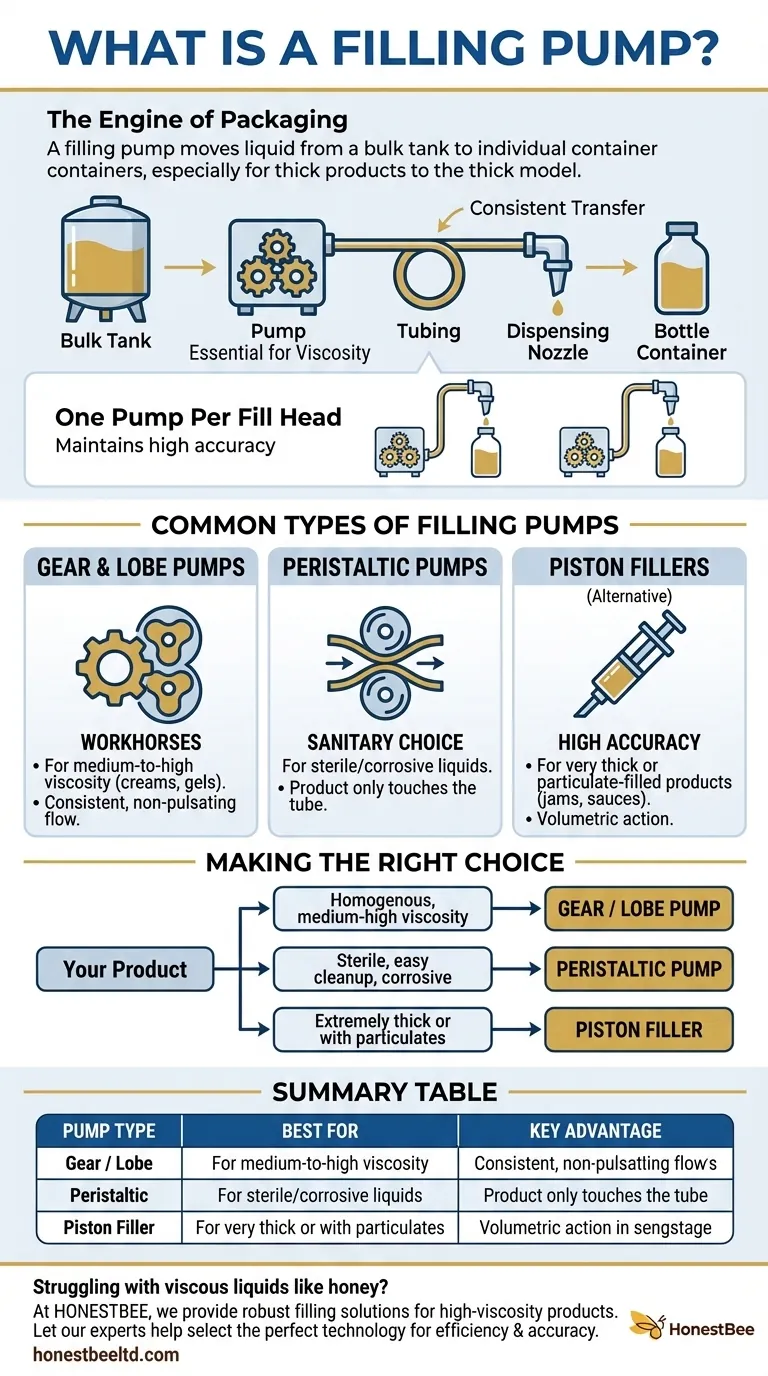

At its core, a filling pump is the engine inside a packaging machine designed to move a liquid product from a bulk tank into individual containers. These pumps are the critical component that provides the force necessary to transfer products that are too thick or viscous to flow easily by gravity alone.

The term "filling pump" refers not to a single device, but to a category of mechanisms used in liquid filling machines. The crucial insight is that the specific type of pump—such as gear, lobe, or peristaltic—is chosen based on the unique characteristics of the liquid being packaged, like its viscosity and sanitary requirements.

How Filling Pumps Power the Packaging Process

A filling machine's primary job is to dispense a precise, repeatable volume of product into bottles, jars, or other containers. The pump is what makes this happen reliably, especially when dealing with challenging products.

The Core Function: Consistent Transfer

The pump draws the product from a holding tank or hopper and drives it through tubing to one or more dispensing nozzles. This ensures a consistent, controllable flow rate.

Why Pumps Are Essential for Viscosity

For thin, free-flowing liquids like water, gravity may be sufficient. However, for medium-to-high viscosity products like honey, lotions, or sauces, a pump provides the positive force needed to move the liquid accurately.

One Pump Per Fill Head

On automated filling lines with multiple nozzles, each nozzle is typically fed by its own dedicated pump. This design ensures that every container receives an equal volume simultaneously, maintaining high accuracy across the entire production run.

Common Types of Filling Pumps Explained

Different liquids present different challenges, from sanitation to thickness. The industry has developed several pump technologies to meet these specific needs.

Gear and Lobe Pumps: The Workhorses

These are positive displacement pumps. They use rotating, interlocking gears or lobes to trap and move a specific volume of product with each rotation.

This mechanism provides a consistent, non-pulsating flow, making it an excellent choice for a wide range of medium-to-high viscosity liquids like creams and gels.

Peristaltic Pumps: The Sanitary Choice

Peristaltic pumps work by using rollers to squeeze a flexible tube, pushing the liquid forward in a motion similar to peristalsis in the human digestive system.

The key advantage is that the product only touches the inside of the tube. This makes them ideal for sterile, sensitive, or corrosive liquids, as the tube can be easily replaced between batches for perfect sanitation.

Understanding the Alternatives and Trade-offs

While pump fillers are common, they are not the only solution. Understanding the primary alternative helps clarify when a pump is the right choice.

The Main Alternative: Piston Fillers

A piston filler operates more like a syringe. A valve opens, allowing product to fill a cylinder. The valve then shifts, and a piston pushes the precisely measured volume out through the nozzle.

Piston fillers are not technically "pump fillers" because their action is volumetric rather than continuous. They excel at handling very thick products and are especially effective for liquids containing large particulates, like chunky salsas or fruit preserves.

Choosing Based on Your Product

The decision between a pump filler and a piston filler comes down to the product itself. Continuous-flow pumps (gear, lobe) are great for homogenous liquids, while piston fillers offer high accuracy for a wider range of viscosities and products with solids.

Operational Scale

Both pump and piston technologies can be found in various machine configurations. This ranges from a simple tabletop machine for small batches to fully automated, multi-head systems integrated into a large-scale production line.

Making the Right Choice for Your Product

Selecting the correct filling technology is critical for efficiency, accuracy, and product integrity. Your decision should be guided by the nature of your liquid.

- If your primary focus is a homogenous, medium-to-high viscosity liquid (like lotions or honey): A gear or lobe pump filler is a standard and highly effective solution.

- If your primary focus is sterility, easy cleanup, or a corrosive product: A peristaltic pump is the superior choice due to its isolated product path.

- If your primary focus is an extremely thick product or one containing particulates (like jams or sauces): A piston filler will likely provide the best accuracy and performance.

Understanding these core mechanisms empowers you to select the precise technology your product demands for successful packaging.

Summary Table:

| Pump Type | Best For | Key Advantage |

|---|---|---|

| Gear / Lobe | Medium-to-high viscosity liquids (creams, gels, honey) | Consistent, non-pulsating flow |

| Peristaltic | Sterile, sensitive, or corrosive liquids | Product only touches a disposable tube |

| Piston Filler | Extremely thick liquids or products with particulates | High accuracy for challenging products |

Struggling to package viscous liquids like honey or creams accurately?

At HONESTBEE, we understand the critical role that reliable filling equipment plays in your operation. As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, we provide robust filling solutions designed to handle the unique challenges of high-viscosity products.

Let our experts help you select the perfect filling pump technology to boost your packaging line's efficiency and accuracy. Contact HONESTBEE today to discuss your specific needs and get a tailored solution!

Visual Guide

Related Products

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- HONESTBEE 24 Head Rotary Bottle Washing Machine

People Also Ask

- Why is the pre-sterilization of honey suction equipment critical for Heterotrigona itama? Prevent Rapid Spoilage

- What is the purpose of honey pumps? Protect Honey Quality and Boost Efficiency

- What role do honey pumps play in the honey processing workflow? Optimize Efficiency and Preserve Quality

- What are the types of honey pumps? Choose the Right Pump for Your Apiary

- What types of pumps are used in honey processing systems? Optimize Your Production with the Right Technology

- Why Use Industrial-grade DC Motors in Honey Suction Machines? Scale Your Stingless Bee Operation with Efficiency

- How does portable honey suction equipment function? Non-Invasive Extraction for Heterotrigona itama

- What are the technical advantages of using vacuum honey suction pumps? Upgrade to Non-Destructive Harvesting