At its core, a honey settling tank is a container used to clarify raw honey after extraction. It leverages gravity to allow lighter impurities, such as wax particles, air bubbles, and other debris, to naturally float to the surface over a period of time, leaving purer, clearer honey below that can be drained off for bottling.

The true purpose of a settling tank is not just to hold honey, but to improve its clarity and texture using a gentle, natural process that avoids the potential downsides of aggressive mechanical filtering.

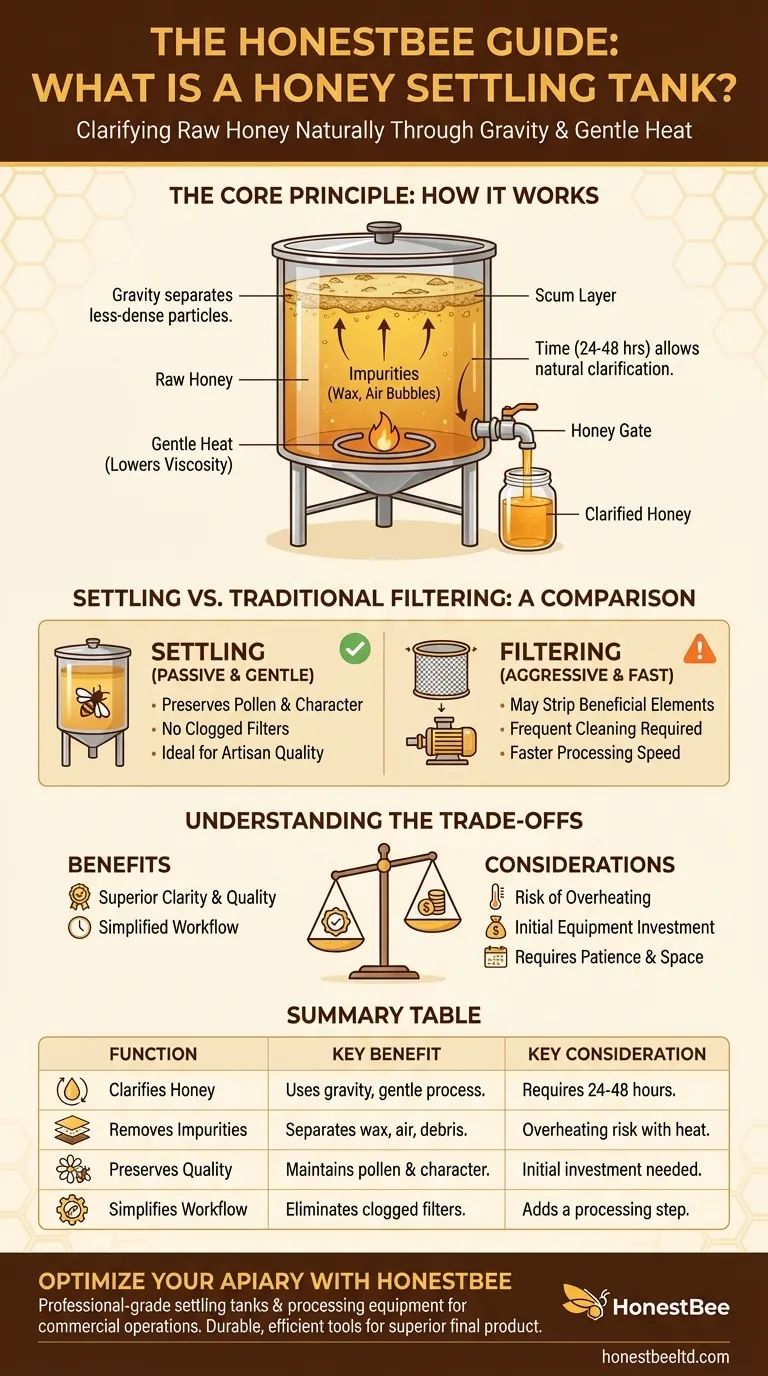

The Core Principle: How Settling Clarifies Honey

A settling tank, sometimes called a ripener or clearing tank, works by harnessing a few fundamental properties of honey. Understanding these principles is key to understanding its value.

Leveraging Gravity and Density

Honey is significantly denser than the impurities introduced during extraction. Particles of beeswax, wood splinters from frames, and even air bubbles whipped into the honey are all lighter than the honey itself.

When left undisturbed in a tank, gravity causes these less-dense materials to slowly rise to the top.

The Role of Gentle Heat

Raw honey is highly viscous, meaning it is thick and flows slowly. This thickness can trap impurities and slow their natural separation.

Many settling tanks are gently heated to lower the honey's viscosity. A slightly warmer, more fluid honey allows bubbles and wax to rise to the surface much more quickly and completely.

The Outcome: Cleaner, Clearer Honey

After a day or two, a distinct layer of foam and wax, often called "scum," will form on the surface.

The settling tank is designed with a honey gate or valve near the bottom. This allows you to drain the clarified honey from below the layer of impurities, which can then be skimmed off and processed separately.

Settling Tank vs. Traditional Filtering

While both settling and filtering aim to clean honey, they are fundamentally different processes with distinct advantages.

The Settling Advantage: A Gentler Process

Aggressive filtering, especially through very fine mesh, can remove beneficial pollen grains that are a natural part of honey. Settling is a passive process that is less likely to strip these elements out.

This method preserves more of the honey's natural character, which is a key selling point for many artisan honey producers.

Avoiding Clogged Filters

Straining raw, unheated honey can be a frustrating and slow process. Filters quickly become clogged with wax, requiring frequent cleaning or replacement.

A settling tank completely bypasses this mechanical problem, offering a more hands-off clarification method. For many small-scale beekeepers, settling is sufficient and removes the need for fine filtering altogether.

Understanding the Trade-offs

While effective, using a settling tank is not without its considerations. It represents a choice between speed, investment, and final product characteristics.

The Factor of Time

Settling is not an instant process. It requires patience, typically taking 24 to 48 hours for the honey to clarify properly, even with gentle heat. Filtering can be a faster method if you need to bottle your honey immediately after extraction.

The Risk of Overheating

If you use a heated tank, it is critical to use one with a reliable thermostat. Overheating honey can destroy its delicate enzymes, degrade its flavor and aroma, and increase its HMF (hydroxymethylfurfural) levels, which is a measure of heat damage and age. The goal is to warm, not cook.

Equipment Cost and Workflow

A dedicated settling tank is an additional piece of equipment that requires an initial investment and space in your processing area. The workflow involves moving honey from your extractor into the settling tank (often with a honey pump), waiting for it to clear, and then draining it into a bottling tank.

Making the Right Choice for Your Operation

Deciding whether to use a settling tank depends entirely on your production goals, scale, and philosophy.

- If your primary focus is preserving the raw, natural character of your honey: A settling tank is an excellent choice as it's a gentler clarification method than fine filtering.

- If your primary focus is simplicity and a low-maintenance workflow: A settling tank can replace the need for complex, multi-stage filter systems that clog easily.

- If your primary focus is maximum speed and volume for a commercial market: You may need to combine coarse straining with a more robust, high-speed filtering system to meet bottling demands quickly.

Ultimately, a settling tank empowers you to produce clearer, higher-quality honey by working with its natural properties, not against them.

Summary Table:

| Function | Key Benefit | Key Consideration |

|---|---|---|

| Clarifies Honey | Uses gravity for a gentle, natural process | Requires 24-48 hours for completion |

| Removes Impurities | Separates wax, air bubbles, and debris | Risk of overheating with heated tanks |

| Preserves Quality | Maintains beneficial pollen and natural character | Initial equipment investment required |

| Simplifies Workflow | Eliminates clogged filters and frequent cleaning | Adds a step to the honey processing workflow |

Ready to produce clearer, higher-quality honey while preserving its natural character?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the professional-grade settling tanks and honey processing equipment needed to optimize your workflow. Our wholesale-focused operations ensure you get the durable, efficient tools for a superior final product.

Contact our experts today to discuss the best honey settling solutions for your operation's scale and goals.

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- How should a honey press be cleaned after it has been used? Essential Maintenance Tips for Your Harvest Tools

- What are the main characteristics of a honey press? High-Quality Extraction for Small-Scale Beekeeping

- How does a honey press help beekeepers meet the demand for chunk honey? Craft Authentic, Raw Hive Products

- How should a new honey press be prepared before its first use? Essential Steps for Pure Honey Production

- How does using a honey press affect comb integrity and subsequent honey production? Balancing Yield and Quality