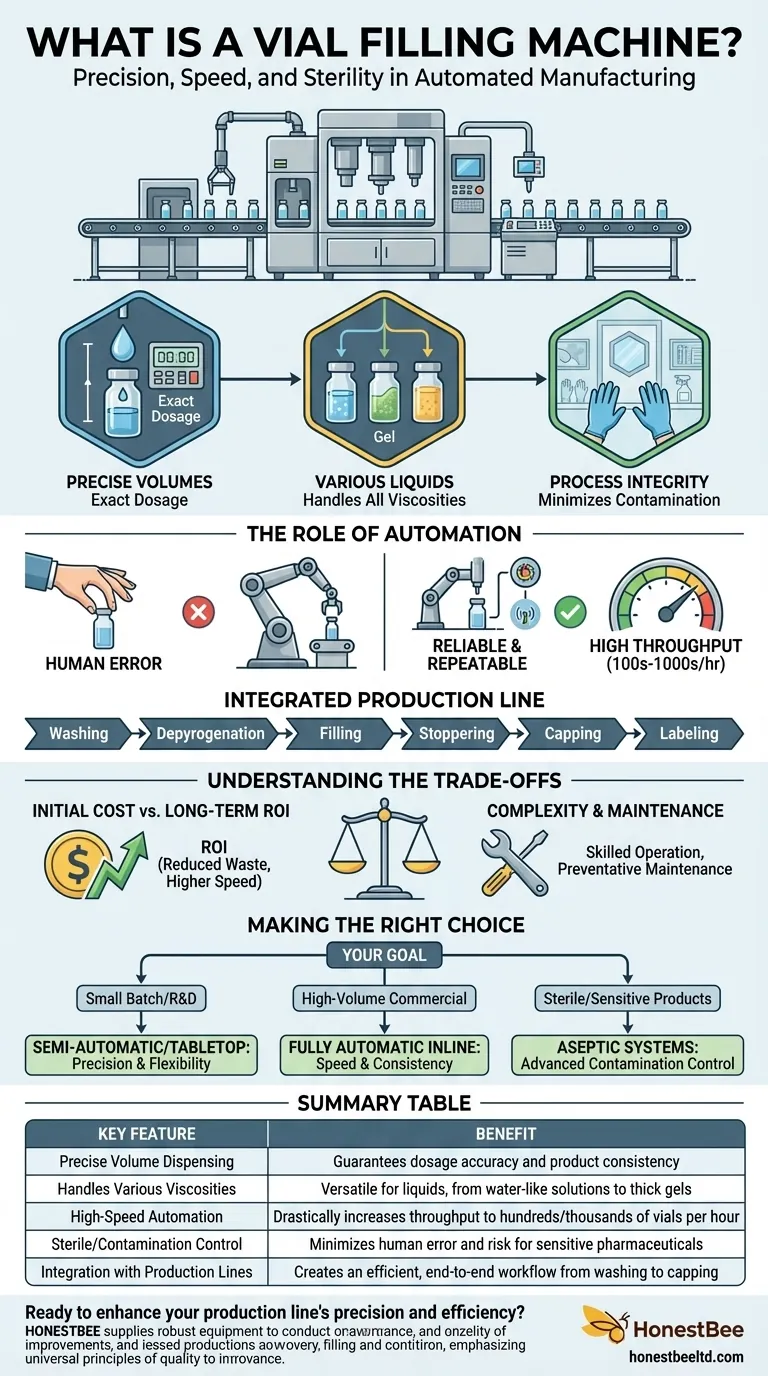

At its core, a vial filling machine is a specialized piece of equipment designed to accurately dispense liquids into small containers known as vials. These automated systems are indispensable in industries like pharmaceuticals, where the precision, speed, and sterility of the filling process are critical for product safety and efficacy. They handle fluids of various viscosities, ensuring each vial is filled to an exact, predetermined volume with minimal human intervention.

The true purpose of a vial filling machine is not simply to fill containers, but to remove human error from a critical manufacturing step. It provides a reliable and repeatable process that guarantees product integrity, dosage accuracy, and operational speed at scale.

The Core Function: Precision and Control

The primary value of a vial filling machine comes from its ability to perform its task with an exceptional degree of accuracy, far surpassing what is possible manually.

Dispensing Exact Volumes

These machines are programmed to dispense a precise volume of liquid, a crucial factor in the pharmaceutical industry where dosage accuracy is paramount. This programmatic control ensures that every vial in a batch, whether it's the first or the ten-thousandth, contains the exact same amount of product.

Handling Various Liquid Types

Modern filling machines are engineered to work with a wide range of liquids. They can manage everything from low-viscosity, water-like solutions to thicker, more viscous fluids like suspensions or gels, using different pump technologies to ensure a smooth and accurate fill regardless of the product's properties.

Ensuring Process Integrity

In pharmaceutical and biotech applications, preventing contamination is non-negotiable. Vial fillers are often designed for use in sterile environments, built with materials that are easy to clean and sterilize. The automation itself minimizes human contact with the product, significantly reducing the risk of contamination.

The Role of Automation in Vial Filling

Automation is what transforms a simple dispensing task into a high-throughput, reliable manufacturing process. It is the key to achieving both quality and scale.

Increasing Throughput

An automatic vial filler can process hundreds or even thousands of vials per hour, a rate impossible to achieve manually. This high throughput is essential for commercial-scale manufacturing, allowing companies to meet market demand efficiently.

Reducing Human Intervention

By automating the filling, stoppering, and often capping processes, these machines drastically reduce the need for direct human involvement. This not only lowers labor costs but, more importantly, it minimizes the primary source of process variability and potential contamination: human error.

Integrating into a Production Line

Vial fillers are rarely standalone units. They are typically part of a larger, integrated "filling line" that can include vial washing, depyrogenation (sterilization), stoppering, cap sealing, and labeling. This seamless integration creates an efficient, end-to-end production workflow.

Understanding the Trade-offs

While highly beneficial, adopting this technology requires a clear understanding of the associated investments and operational considerations.

Initial Cost vs. Long-Term ROI

Fully automatic vial filling lines represent a significant capital investment. However, this upfront cost is weighed against the long-term return on investment, which includes reduced product waste, lower labor expenses, higher production speed, and enhanced regulatory compliance.

Complexity and Maintenance

Sophisticated machinery requires skilled personnel for operation, calibration, and maintenance. Regular, preventative maintenance is critical to ensure the machine continues to operate within its precise specifications and to prevent costly downtime.

Flexibility vs. Specialization

Some machines are optimized for a specific vial size and product, offering maximum speed and efficiency. Others provide more flexibility, allowing for "change parts" to accommodate different vial dimensions and product types. This flexibility often comes at the cost of slightly lower throughput or a more complex changeover process.

Making the Right Choice for Your Goal

Selecting the appropriate vial filling technology depends entirely on your specific production scale, product type, and regulatory environment.

- If your primary focus is research, development, or small-batch production: A semi-automatic or tabletop filling machine offers an excellent balance of precision, lower initial cost, and flexibility for handling various products.

- If your primary focus is high-volume commercial manufacturing: A fully automatic, integrated inline system is the only way to achieve the necessary speed, consistency, and minimal human intervention required for large-scale operations.

- If your primary focus is handling sterile injectables or sensitive biologics: Prioritize machines specifically designed for aseptic (sterile) environments, featuring advanced contamination controls and compatibility with isolator or RABS technology.

Ultimately, viewing a vial filler as a strategic asset for quality control and operational efficiency will empower you to make the most informed decision for your project.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Precise Volume Dispensing | Guarantees dosage accuracy and product consistency. |

| Handles Various Viscosities | Versatile for liquids, from water-like solutions to thick gels. |

| High-Speed Automation | Drastically increases throughput to hundreds/thousands of vials per hour. |

| Sterile/Contamination Control | Minimizes human error and risk for sensitive pharmaceuticals. |

| Integration with Production Lines | Creates an efficient, end-to-end workflow from washing to capping. |

Ready to enhance your production line's precision and efficiency?

At HONESTBEE, we supply robust beekeeping supplies and equipment to commercial apiaries and distributors. While our core expertise is in beekeeping, the principles of reliable, high-quality equipment are universal. If you are exploring equipment solutions for precision tasks, our wholesale-focused operations demonstrate a commitment to durability and performance.

Contact our team today to discuss your equipment needs and discover how we can support your operational goals with reliable, high-quality supplies.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- In what ways do specialized honey packaging and bottling machines affect the economic efficiency of large-scale apiaries?

- What is the function of a twin honey stick machine? Double Your Honey Stick Production

- What auxiliary machines are used with honey fillers? Build a Complete, Automated Packaging Line

- What benefits do industrial automated filling machines provide for honey? Scale Your Production with Precision

- What role does the automated honey-filling machine play in the value chain of guava pollination byproducts? Boost ROI

- How does professional labeling and filling equipment add value to stingless bee products? Maximize Your Market Premium

- How do industrial honey filling machines assist producers in remaining competitive? Beat Imports with Precision

- What are the core advantages of using automated honey-filling machines? Boost Efficiency & Precision for Your Apiary