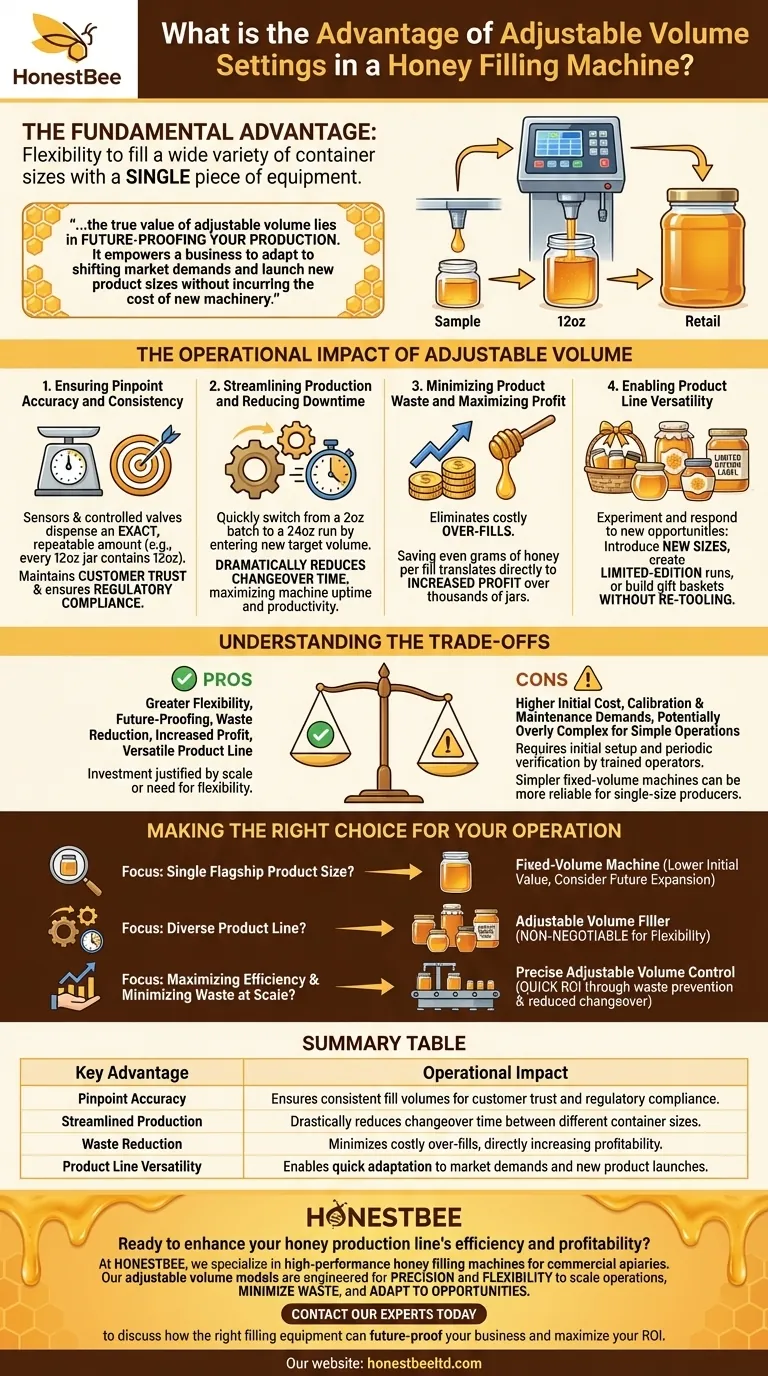

The fundamental advantage of adjustable volume settings in a honey filling machine is the flexibility to fill a wide variety of container sizes with a single piece of equipment. This feature allows producers to switch from filling small sample jars to large retail containers with precision, ensuring operational agility and product consistency across their entire line.

While the immediate benefit is flexibility, the true value of adjustable volume lies in future-proofing your production. It empowers a business to adapt to shifting market demands and launch new product sizes without incurring the cost of new machinery.

The Operational Impact of Adjustable Volume

Adjustable volume control is more than a convenience; it is a central feature that directly impacts efficiency, cost, and brand perception. It transforms a simple packaging task into a strategic part of your operation.

Ensuring Pinpoint Accuracy and Consistency

A machine with adjustable settings uses sensors and precisely controlled valves to dispense an exact, repeatable amount of honey. This ensures that every 12-ounce jar contains 12 ounces of product, not 11.8 or 12.2.

This level of accuracy is critical for maintaining customer trust and complying with weights and measures regulations. It guarantees that every customer receives the same value.

Streamlining Production and Reducing Downtime

Imagine needing to fill a batch of 2-ounce wedding favors followed by a run of 24-ounce retail jars. With adjustable volume, an operator can simply enter the new target volume into the system.

This dramatically reduces the changeover time between different product runs, maximizing the machine's uptime and overall productivity.

Minimizing Product Waste and Maximizing Profit

Inaccurate filling leads to two costly problems: under-fills that create legal and reputational risk, and over-fills that give away free product.

By precisely controlling the fill volume, the machine eliminates costly over-fills. Over the course of thousands of jars, saving even a few grams of honey per fill translates directly to increased profit.

Enabling Product Line Versatility

The market is not static. An adjustable volume filler gives you the power to experiment and respond to new opportunities.

You can easily introduce a new product size, create limited-edition runs, or build gift baskets with various jar sizes, all without needing to re-tool your entire production line.

Understanding the Trade-offs

While highly beneficial, this feature is not without its considerations. Objectively weighing the pros and cons is key to making a sound investment.

Initial Cost vs. Long-Term Value

Machines with sophisticated, digitally-controlled adjustable volume systems typically have a higher upfront cost than simpler, fixed-volume models.

The investment must be justified by the need for flexibility or the scale of production where waste reduction creates a clear return on investment.

Calibration and Maintenance Demands

To maintain their high accuracy, these systems require proper initial setup and periodic calibration.

Operators must be trained to verify the fill volumes and make minor adjustments as needed. This represents a small but necessary commitment to maintenance and quality control.

When Simplicity is Better

For a producer who is certain they will only ever sell one standard jar size, a simpler, fixed-volume machine can be a more reliable and cost-effective solution.

In this scenario, the added complexity and cost of adjustable settings offer no practical advantage.

Making the Right Choice for Your Operation

The decision to invest in adjustable volume control should be driven by your specific business goals, both now and in the future.

- If your primary focus is launching a single, flagship product size: A fixed-volume machine may offer better initial value, but carefully consider if you might want to expand your offerings later.

- If your primary focus is offering a diverse product line: An adjustable volume filler is a non-negotiable feature that provides the core flexibility your business model requires.

- If your primary focus is maximizing efficiency and minimizing waste at scale: A machine with precise, easily adjustable volume control will quickly pay for itself by preventing over-fills and reducing changeover time.

Ultimately, choosing the right filling technology is about aligning your equipment's capabilities with your business's strategic vision for growth.

Summary Table:

| Key Advantage | Operational Impact |

|---|---|

| Pinpoint Accuracy | Ensures consistent fill volumes for customer trust and regulatory compliance. |

| Streamlined Production | Drastically reduces changeover time between different container sizes. |

| Waste Reduction | Minimizes costly over-fills, directly increasing profitability. |

| Product Line Versatility | Enables quick adaptation to market demands and new product launches. |

Ready to enhance your honey production line's efficiency and profitability?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with high-performance honey filling machines. Our adjustable volume models are engineered to provide the precision and flexibility you need to scale your operations, minimize waste, and adapt to market opportunities.

Contact our experts today to discuss how the right filling equipment can future-proof your business and maximize your ROI.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- How do automated honey filling machines contribute to the commercial competitiveness of honey products? Master Your Market

- How do advanced honey refining and honey-filling machines contribute to large-scale commercial honey production?

- What is a key feature of the new generation of the honey filling machine? The Advanced Electronic Control Unit

- What is the automated process of a jar or bottle packing machine for honey? Optimize Your Apiary Production

- How do automated honey-filling and packaging machines benefit small-scale producers? Your Key to Retail Market Entry

- How do precision pH meters and automatic titration systems ensure honey quality before automatic filling?

- How do automated honey filling machines contribute to packaging quality? Boost Consistency, Hygiene, and Market Appeal

- How does the integration of automated honey-filling machines with hive recognition technology create value? Optimize Now