The best way to filter honey depends entirely on your end goal, but for most beekeepers, the process starts with simple gravity straining. This involves pouring extracted honey through a coarse metal or nylon strainer placed over a bucket to remove large impurities like beeswax, wood splinters, and bee parts. This single step is often all that is needed to produce clean, high-quality raw honey.

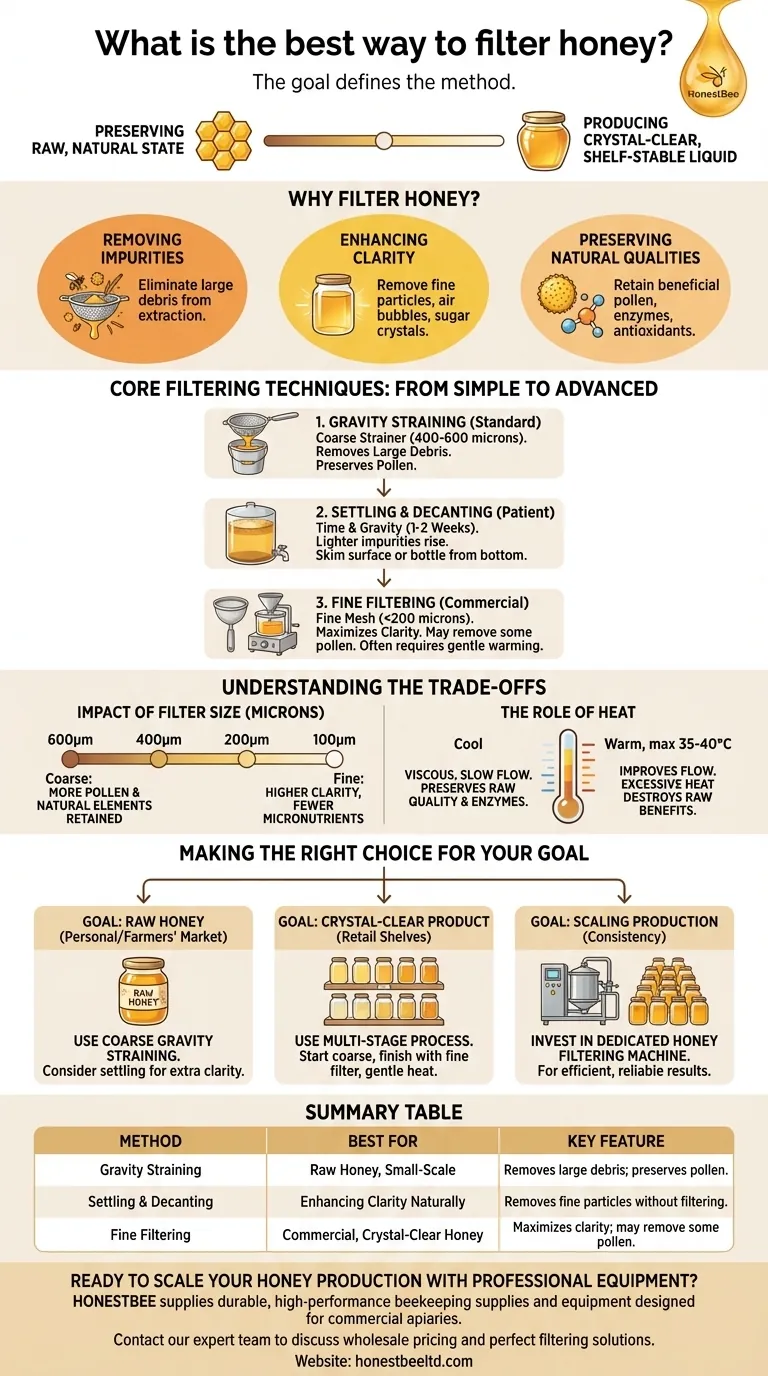

The core decision in filtering honey is not about finding one "best" method, but choosing a point on the spectrum between preserving its raw, natural state and producing a perfectly clear, shelf-stable liquid for commercial appeal.

Why Filter Honey? The Goal Defines the Method

Before choosing your equipment, you must first define what "quality" means to you. The ideal filtering process is one that aligns perfectly with your vision for the final product.

Removing Physical Impurities

The most basic goal of filtering is to remove unwanted physical debris that gets mixed in during extraction.

This includes bits of wax cappings, bee parts, and splinters from the hive frames. Every method of filtering, from simple to complex, achieves this primary goal.

Enhancing Clarity and Shelf Appeal

For beekeepers who sell their honey, appearance is critical. Filtering removes fine particles, air bubbles, and even tiny sugar crystals that can make honey look cloudy.

A crystal-clear product often appears more appealing to customers and is a sign of a consistent, professional operation.

Preserving Natural Qualities

Many consumers and beekeepers prefer honey that is as close to its natural state as possible. This means preserving beneficial components like pollen, enzymes, and antioxidants.

This "raw" honey is typically minimally processed, which has direct implications for how aggressively it should be filtered.

Core Filtering Techniques: From Simple to Advanced

Your filtering strategy can be a single step or a multi-stage process depending on your goals and the scale of your operation.

Method 1: Gravity Straining (The Standard Approach)

This is the most common and straightforward method, especially for small-scale operations.

Honey is simply poured through a coarse strainer resting on a food-grade bucket. The force of gravity does all the work. A stainless steel strainer is ideal for catching the largest pieces of wax and debris while allowing valuable pollen to pass through.

For many, this is both the first and last step required.

Method 2: Settling and Decanting (The Patient Approach)

This technique uses time and gravity to clarify honey without any filter at all.

After an initial straining to remove large debris, the honey is left to sit undisturbed in a tank or bottling container for one to two weeks. Lighter impurities, like fine wax particles and air bubbles, will naturally rise to the surface.

You can then skim this layer off the top or, more effectively, bottle the clear honey from a spigot at the bottom of the container, leaving the sediment and surface foam behind.

Method 3: Fine Filtering (The Commercial Approach)

To achieve maximum clarity, a finer filter is required. This often involves using fine-mesh nylon filters or specialized honey filtering machines.

These systems can remove even the smallest particles, resulting in a brilliantly clear product. However, this level of filtering requires more pressure or gentle heat to help the thick honey pass through the fine mesh.

Understanding the Trade-offs

Choosing a filtering method involves balancing clarity against the preservation of natural compounds. There is no right or wrong, only what is appropriate for your specific goals.

The Impact of Filter Size

The size of the holes in your filter (measured in microns) is the most critical factor.

Coarse strainers (around 400-600 microns) remove visible debris but leave pollen and other beneficial microscopic elements.

Fine filters (200 microns or less) produce clearer honey but can begin to remove pollen grains, which some consumers actively seek for their potential health benefits.

The Role of Heat

Honey is viscous and flows slowly, especially when cool. Gently warming it (to no more than 95-105°F or 35-40°C) can make it pass through filters much more easily.

However, excessive heat is the enemy of raw honey. High temperatures will destroy its delicate enzymes and aromas. If preserving the "raw" quality is your goal, you must avoid high heat and rely on gravity, patience, or a filtering system designed for unpasteurized honey.

What Defines "Raw" Honey

While definitions vary, "raw honey" generally means it has not been pasteurized (heated to high temperatures) and has only been strained, not finely filtered.

This ensures the final product contains all the natural pollen, enzymes, and other micronutrients present when it left the hive.

Making the Right Choice for Your Goal

Select your method based on the product you want to create and the audience you want to serve.

- If your primary focus is raw honey for personal use or a farmers' market: Rely on coarse gravity straining to remove debris, and consider letting the honey settle for extra clarity.

- If your primary focus is a crystal-clear product for retail shelves: Use a multi-stage process, starting with a coarse strainer and finishing with a finer filter, using gentle warming as needed to aid flow.

- If your primary focus is scaling up production for consistency: Investing in a dedicated honey filtering machine will provide the most efficient and reliable results for a marketable product.

Ultimately, mastering honey filtering is about aligning your method with your vision for the final product.

Summary Table:

| Method | Best For | Key Feature | Impact on Honey |

|---|---|---|---|

| Gravity Straining | Raw Honey, Small-Scale | Coarse Filter (400-600 microns) | Removes large debris; preserves pollen. |

| Settling & Decanting | Enhancing Clarity Naturally | Uses Time and Gravity | Removes fine particles without filtering. |

| Fine Filtering | Commercial, Crystal-Clear Honey | Fine Mesh (<200 microns) | Maximizes clarity; may remove some pollen. |

Ready to Scale Your Honey Production with Professional Equipment?

As a beekeeper focused on quality and efficiency, the right filtering equipment is crucial for achieving your goals, whether you prioritize raw honey preservation or commercial-grade clarity. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment—including commercial-grade honey filters and extractors—designed specifically for the needs of commercial apiaries and beekeeping equipment distributors.

We help you maintain product integrity while scaling your operations. Contact our expert team today to discuss wholesale pricing and find the perfect filtering solution for your business.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What role does industrial-grade filtration equipment play in the production of raw honey? Enhance Purity and Quality

- What is the primary function of a honey disintegrator or filter press? Essential Purification for Quality Honey

- What role does low-damage filtration equipment play in the processing of honey and propolis? Preserve Bioactive Integrity

- Why is the use of mechanized honey filtration machines necessary for value addition? Transform Raw Honey into Premium Profit

- What steps are involved in maintaining honey filtering equipment? A Guide to Protecting Your Honey Quality

- How does the decanting process in settling tanks contribute to honey purification? Achieve High Clarity Naturally

- How does the honey filtration process impact the quality of stingless bee honey? Ensure Stability and Clarity

- How do industrial honey filtration and processing equipment prevent AFB? Protect Your Colony with Advanced Containment