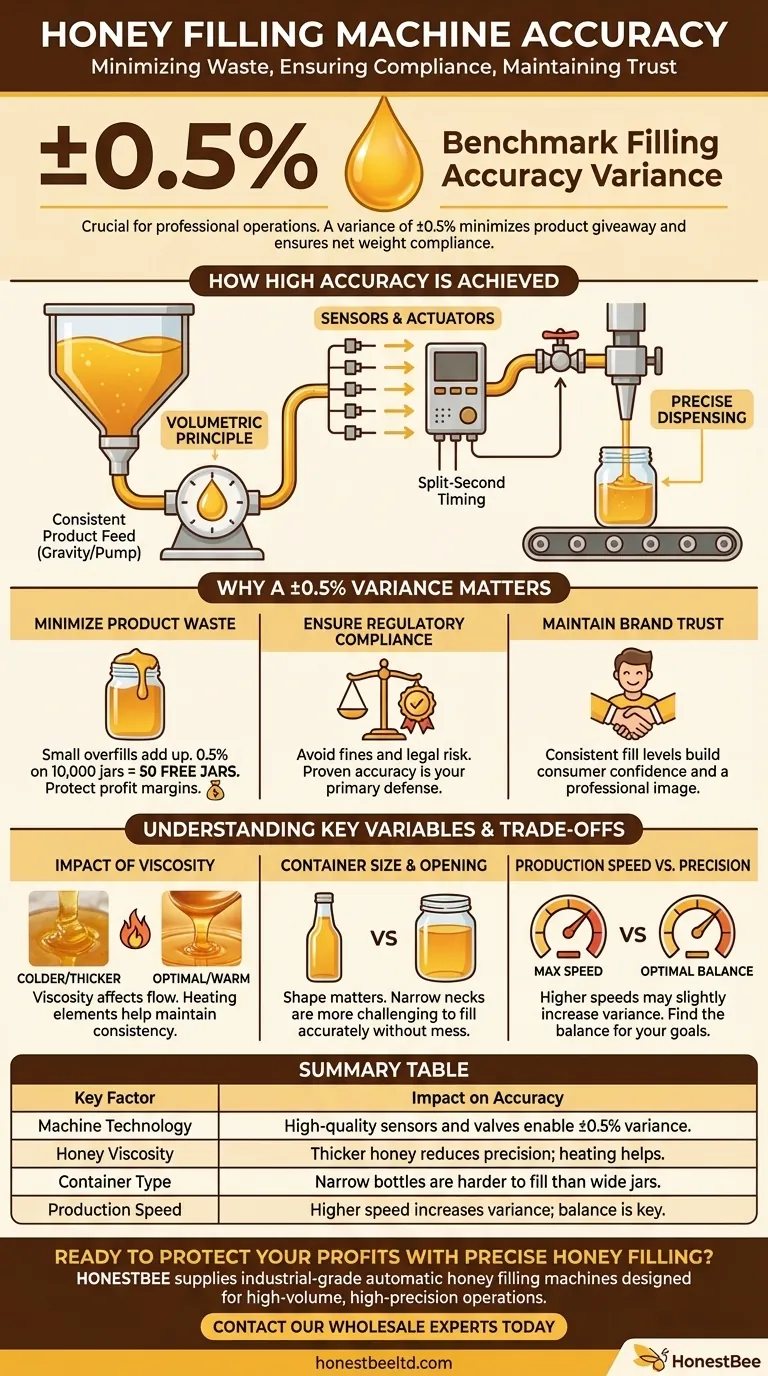

To be precise, a high-quality automatic honey filling machine typically achieves a filling accuracy with a variance of around ±0.5%. This level of precision is critical for professional operations, as it directly minimizes product giveaway, reduces waste, and ensures every container complies with packaging regulations for net weight.

The stated accuracy of a honey filling machine is not a fixed guarantee, but a benchmark. True operational accuracy depends on a combination of the machine's technology, the physical properties of your honey, and the containers you use.

How Machines Achieve High Accuracy

The precision of an automatic filler is not magic; it is the result of a carefully engineered system designed to manage a difficult, viscous product.

The Volumetric Filling Principle

Most automatic honey fillers operate on a volumetric principle. The machine is programmed to dispense a precise volume of honey during each cycle. Honey is held in a hopper and flows to a filling nozzle, ready for dispensing.

The Role of Sensors and Actuators

To ensure each fill is identical, the machine uses a system of sensors, valves, and actuators. These components control the start and stop of the honey flow with split-second timing, guaranteeing the exact programmed volume enters the container.

Consistent Product Feed

For the filling mechanism to be accurate, the supply of honey must be constant. Machines use either a gravity feed or a pump system to move honey from the main hopper to the filling heads, ensuring a continuous and consistent flow that prevents air pockets or pressure changes from affecting the fill volume.

Why a ±0.5% Variance Matters

A variance that seems small on paper has significant financial and regulatory implications in a production environment.

Minimizing Product Waste

Overfilling, even by a small amount, adds up quickly. A 0.5% overfill on 10,000 jars of honey means you have given away 50 full jars of product for free. Higher accuracy directly protects your profit margins.

Ensuring Regulatory Compliance

Consistently underfilling containers is a serious legal risk. It can lead to fines and damage to your brand's reputation. A machine with proven accuracy is your primary defense against non-compliance with weights and measures laws.

Maintaining Brand Trust

Customers expect to receive the amount of product they paid for. Inconsistent fill levels can erode consumer trust and make your product appear unprofessional on the shelf.

Understanding the Key Variables and Trade-offs

Achieving the benchmark accuracy of ±0.5% requires you to account for several factors that can influence a machine's performance.

The Impact of Honey Viscosity

Honey's thickness, or viscosity, is the single most important variable. Thicker, colder honey flows more slowly and can be harder to cut off cleanly, potentially affecting accuracy. Many machines include heating elements in the hopper to maintain a consistent, workable viscosity.

Container Size and Opening

The size and shape of your containers matter. Filling a narrow-necked bottle without dripping is more challenging than filling a wide-mouth jar. The machine's nozzles must be appropriate for your specific packaging to prevent mess and waste, which impacts final accuracy.

Production Speed vs. Precision

There is often a trade-off between maximum filling speed and maximum accuracy. Running a machine at its absolute top speed may slightly increase the filling variance. You must find the optimal balance for your production goals that maintains compliance without sacrificing too much output.

How to Apply This to Your Operation

Choosing a machine requires matching its capabilities to your specific product and business goals.

- If your primary focus is high-volume, standardized production: Prioritize a robust machine that offers a proven balance of speed and accuracy for a consistent honey type and container size.

- If your primary focus is artisanal or premium honey: Invest in a high-precision filler, such as a servo-driven model, that can guarantee the tightest accuracy to protect the high value of your product.

- If your primary focus is operational flexibility: Look for a machine that can be easily adjusted to handle different container sizes and has controls for managing various honey viscosities.

Understanding these factors empowers you to select a machine that serves as a reliable foundation for a profitable and compliant operation.

Summary Table:

| Key Factor | Impact on Filling Accuracy |

|---|---|

| Machine Technology | High-quality sensors and valves enable ±0.5% variance. |

| Honey Viscosity | Thicker, colder honey can reduce precision; heating elements help. |

| Container Type | Narrow-necked bottles are more challenging to fill accurately than wide-mouth jars. |

| Production Speed | Higher speeds can slightly increase variance; a balance is key. |

Ready to protect your profits with precise honey filling?

For commercial apiaries and beekeeping equipment distributors, consistent accuracy is non-negotiable. HONESTBEE supplies industrial-grade automatic honey filling machines designed for high-volume, high-precision operations. We help you minimize product giveaway and ensure regulatory compliance.

Contact our wholesale experts today to find the perfect filling solution for your business.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- What are the benefits of using a phenology-based prediction system? Boost Honey Processing & Filling Efficiency

- What role do automatic honey-filling machines play in the commercial packaging of honey? Scaling for Global Markets

- What is the role of automated filling and packaging equipment in honey processing? Boost Efficiency & Preserve Quality

- How do automated honey filling lines ensure commercial value? Boost Your Honey Brand's Competitiveness and ROI

- What technical advantages do industrial honey filling machines provide? Boost Precision and Quality in Processing

- How does automated honey filling equipment contribute to the industrial value of honey? Scale Your Premium Honey Brand

- What technical challenges do industrial honey-filling machines address? Solving Efficiency and Hygiene in Production

- What additional support is available for selecting a honey packaging machine? Get Expert Guidance for Your Apiary