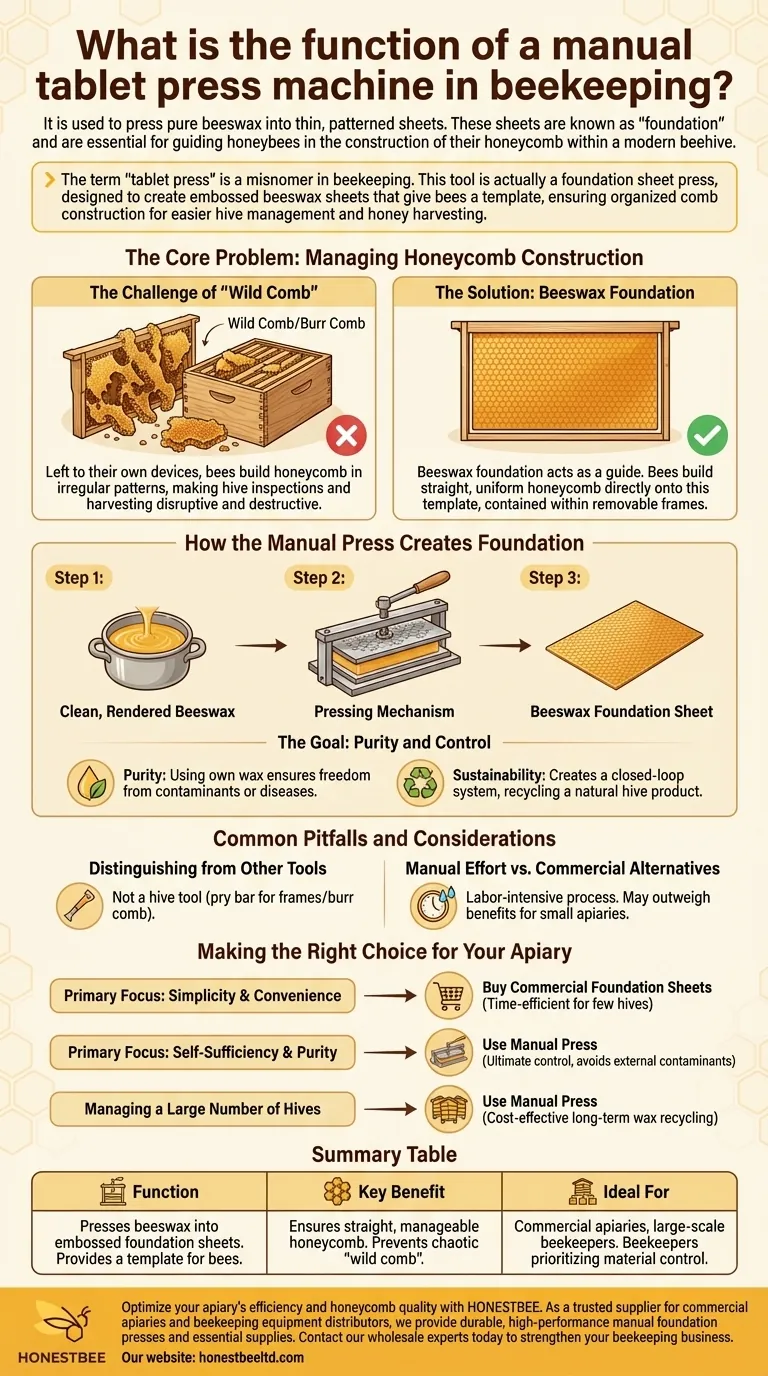

In the context of beekeeping, the tool often called a manual tablet press serves a single, specific function: It is used to press pure beeswax into thin, patterned sheets. These sheets are known as "foundation" and are essential for guiding honeybees in the construction of their honeycomb within a modern beehive.

The term "tablet press" is a misnomer in beekeeping. This tool is actually a foundation sheet press, designed to create embossed beeswax sheets that give bees a template, ensuring organized comb construction for easier hive management and honey harvesting.

The Core Problem: Managing Honeycomb Construction

To understand the function of this press, it's essential to first understand the problem it solves. Beekeepers need a way to manage how and where their bees build comb.

The Challenge of "Wild Comb"

Left to their own devices, bees will build honeycomb in irregular patterns, often connecting it across frames and to the walls of the hive. This "wild comb" or "burr comb" makes it nearly impossible for a beekeeper to remove frames.

Inspecting the hive for health, locating the queen, and harvesting honey become incredibly disruptive and destructive processes without orderly comb.

The Solution: Beeswax Foundation

Beeswax foundation is the solution to this chaos. It's a thin sheet of beeswax embossed with the hexagonal cell pattern that bees naturally use.

When placed in a frame, this foundation acts as a guide or starter strip. The bees build their comb directly onto this template, resulting in straight, uniform honeycomb that is contained neatly within the removable frames.

How the Manual Press Creates Foundation

A manual press allows a beekeeper to create their own foundation sheets instead of buying them commercially. This offers significant advantages in purity and self-sufficiency.

The Pressing Mechanism

The process is straightforward. A beekeeper takes clean, rendered beeswax from their own hives and presses it between the two plates of the machine.

These plates are engraved with the hexagonal cell base pattern. The pressure imprints this pattern onto the wax, creating a perfect sheet of foundation ready to be placed into a frame.

The Goal: Purity and Control

The primary reason a beekeeper invests in a press is to control the materials inside their hives. Using wax from their own bees ensures the foundation is pure and free from potential contaminants or diseases.

This recycling of a natural hive product creates a sustainable, closed-loop system within the beekeeper's own apiary.

Common Pitfalls and Considerations

While valuable, this tool is not for every beekeeper. Understanding its context is key to deciding if it's a worthwhile investment.

Distinguishing from Other Tools

It is crucial not to confuse this press with other essential beekeeping equipment. For instance, a hive tool is a completely different item—a small pry bar used to separate frames and scrape away unwanted propolis or burr comb.

Manual Effort vs. Commercial Alternatives

Creating your own foundation with a manual press is a labor-intensive process compared to simply purchasing pre-made sheets.

For beekeepers with only one or two hives, the time, effort, and initial cost of the press may outweigh the benefits of buying foundation as needed.

Making the Right Choice for Your Apiary

Your beekeeping goals will determine whether a manual foundation press is a practical tool for your operation.

- If your primary focus is simplicity and convenience: Buying commercially produced foundation sheets is the most time-efficient choice for managing a few hives.

- If your primary focus is self-sufficiency and purity: Using a press to create foundation from your own wax provides ultimate control over your hive materials and avoids external contaminants.

- If you are managing a large number of hives: A press can become a cost-effective tool for recycling your own beeswax into new foundation over the long term.

Ultimately, this tool empowers beekeepers to create a pure and sustainable cycle of wax production and reuse within their own apiaries.

Summary Table:

| Function | Key Benefit | Ideal For |

|---|---|---|

| Presses beeswax into embossed foundation sheets | Ensures straight, manageable honeycomb | Commercial apiaries, large-scale beekeepers |

| Recycles hive wax for purity | Creates a closed-loop, sustainable system | Beekeepers prioritizing material control |

| Provides a template for bees | Prevents chaotic "wild comb" and simplifies hive inspections | Operations focused on efficiency and hive health |

Optimize your apiary's efficiency and honeycomb quality with HONESTBEE.

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, we provide the durable, high-performance manual foundation presses and other essential beekeeping supplies you need to scale your operations. By creating your own pure beeswax foundation, you gain complete control over hive materials, promote sustainability, and ensure the highest standards of health for your bees.

Contact our wholesale experts today to discuss how our equipment can strengthen your beekeeping business.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

People Also Ask

- What equipment is needed to make beeswax foundation? A Guide to DIY Wax Sheet Production

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What additional preparation is needed for the work area when making beeswax sheets? Set Up a Professional Production Line

- What is the primary function of the manual honeycomb embossing machine? Gain Control Over Your Hive's Foundation