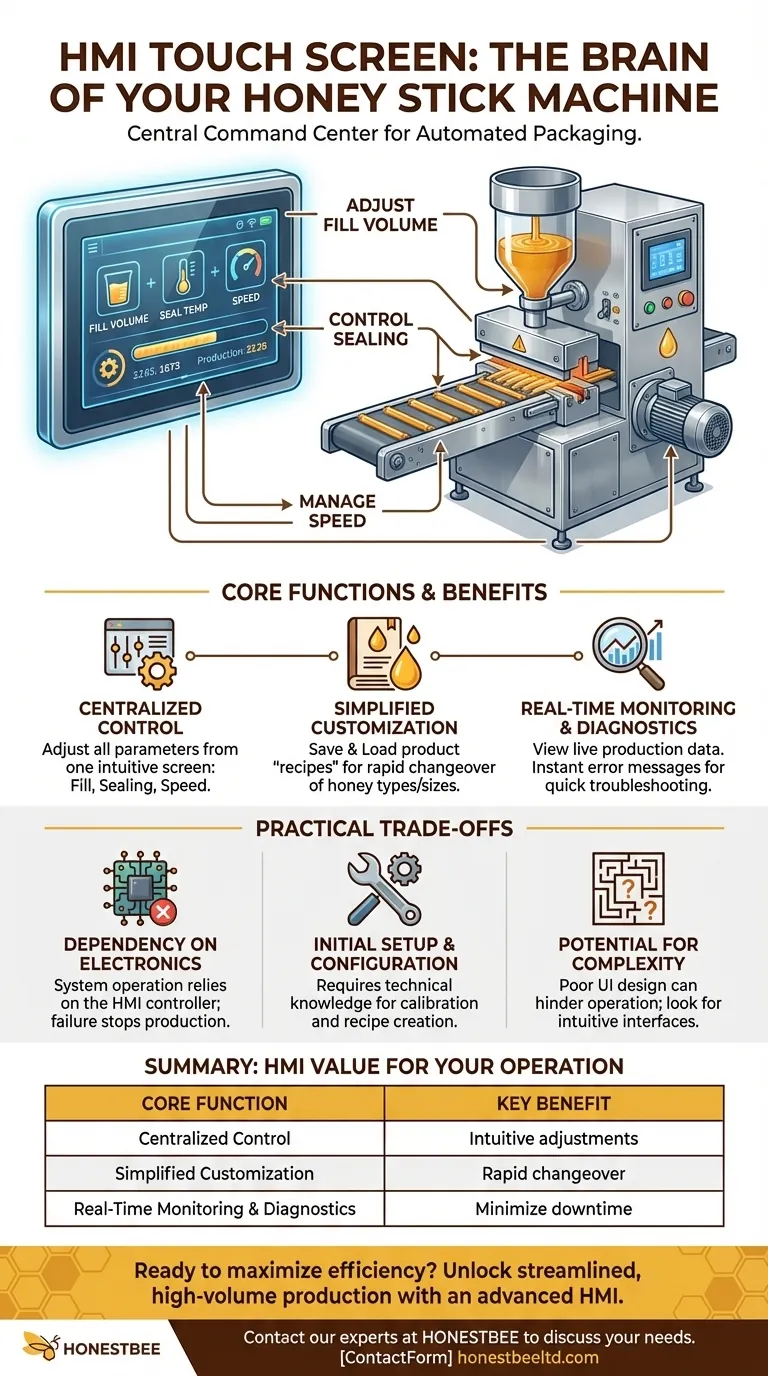

In essence, the HMI (Human-Machine Interface) touch screen on a honey stick machine serves as the central command center for the entire packaging process. It is an intuitive, automated control panel that replaces traditional buttons and dials, allowing an operator to easily manage, customize, and monitor the machine's functions through a graphical interface.

The HMI touch screen transforms complex mechanical processes into simple, on-screen commands. It is the critical component that makes the machine's high-speed automation manageable, customizable, and efficient for the operator.

The Core Functions of the HMI

An HMI is the brain of the automated system, translating human instructions into machine actions. In the context of a honey stick machine, this has several direct impacts on production.

Centralized Control

All operational parameters are consolidated into one place. An operator can use the touch screen to set, adjust, and monitor every critical aspect of the packaging cycle.

This includes adjusting the fill volume of honey, the sealing temperature and pressure for the stick film, and the overall operating speed of the machine.

Simplified Operation and Customization

The graphical nature of an HMI makes the machine significantly easier to operate. Functions are represented by icons and on-screen menus, reducing the learning curve for new staff.

The references highlight "easy customization," which is a key benefit. Operators can create, save, and load different programming options or "recipes" for various products. This allows for rapid changeover between different honey viscosities, stick sizes, or packaging films with a single click.

Real-Time Monitoring and Diagnostics

A modern HMI provides a live overview of the machine's status. It displays production data, such as the total number of sticks packaged, the current output rate, and operational efficiency.

Crucially, it also serves as a diagnostic tool. If a fault occurs, such as a film jam or a sealing error, the HMI will display a specific error message, often highlighting the problem area on a machine graphic. This drastically reduces troubleshooting time and minimizes downtime.

Understanding the Practical Trade-offs

While indispensable for modern automation, an HMI-based system has considerations that differ from simpler, mechanical machines.

Dependency on Electronics

The machine's entire operation is dependent on the HMI and its underlying controller. If the touch screen or its processor fails, the entire machine becomes inoperable until the electronic component is repaired or replaced.

Initial Setup and Configuration

While day-to-day operation is simple, the initial setup requires a degree of technical knowledge. Calibrating sensors, defining the limits for temperature and pressure, and creating the initial product recipes must be done correctly for the machine to function reliably.

Potential for Complexity

A poorly designed HMI can be more confusing than helpful. If the interface is not intuitive, with buried menus or unclear labeling, it can hinder an operator's ability to run the machine efficiently. Well-designed interfaces are a hallmark of a quality machine.

How to Apply This to Your Operation

The decision to prioritize an HMI-equipped machine depends entirely on your production goals.

- If your primary focus is high-volume output: The HMI is essential for managing the speed, consistency, and automation needed for large-scale, multi-lane production.

- If your primary focus is product versatility: The ability to save and load presets is crucial for quickly switching between different products without lengthy manual readjustments.

- If your primary focus is operational efficiency: The HMI reduces operator error, simplifies training, and provides instant diagnostic feedback that is critical for minimizing downtime.

Ultimately, the HMI is the feature that unlocks the full potential of an automated honey stick machine.

Summary Table:

| Core Function | Key Benefit for Your Operation |

|---|---|

| Centralized Control | Adjust fill volume, sealing temperature, and speed from one intuitive screen. |

| Simplified Customization | Save and load product 'recipes' for rapid changeover between different honey types. |

| Real-Time Monitoring & Diagnostics | View production data and get instant error messages to minimize costly downtime. |

Ready to maximize the efficiency and versatility of your honey packaging line?

An advanced HMI touch screen is the key to streamlined, high-volume production. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the robust, wholesale-focused honey stick machines and supplies needed to scale operations.

Let us help you integrate the right automated solution for your specific production goals. Contact our experts today to discuss your needs and get a quote!

Visual Guide

Related Products

- Premium Heat-Resistant Glass Honey Dipper

- 10L Stainless Steel Electric Honey Press Machine

- Modern Honeycomb Pattern Wooden Honey Dipper for Stirring and Drizzling

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Automatic Honey Frame Uncapper Machine for Beekeeping

People Also Ask

- What role do industrial filling and sealing machines play in honey export? Transform Raw Honey into Global Commodities

- What role do automatic honey-filling machines play in the commercial processing of urban honey? Enhancing Purity.

- How does the filling process ensure product integrity and quality? Achieve Precision and Consistency

- How do automated honey filling and processing machines improve the economic resilience of commercial apiaries?

- How do industrial honey filling machines resolve packaging inefficiencies? Boost Your Honey Production Precision

- Why is high-precision industrial filling machinery critical for Mad Honey? Ensure Safe Dosage & Premium Quality

- What role does industrial honey filling equipment play? Scale Your Honey Production and Global Export Potential

- Why is the use of automatic liquid filling machines essential for the commercial scale-up of stingless bee propolis products? Scale Your Brand Efficiently