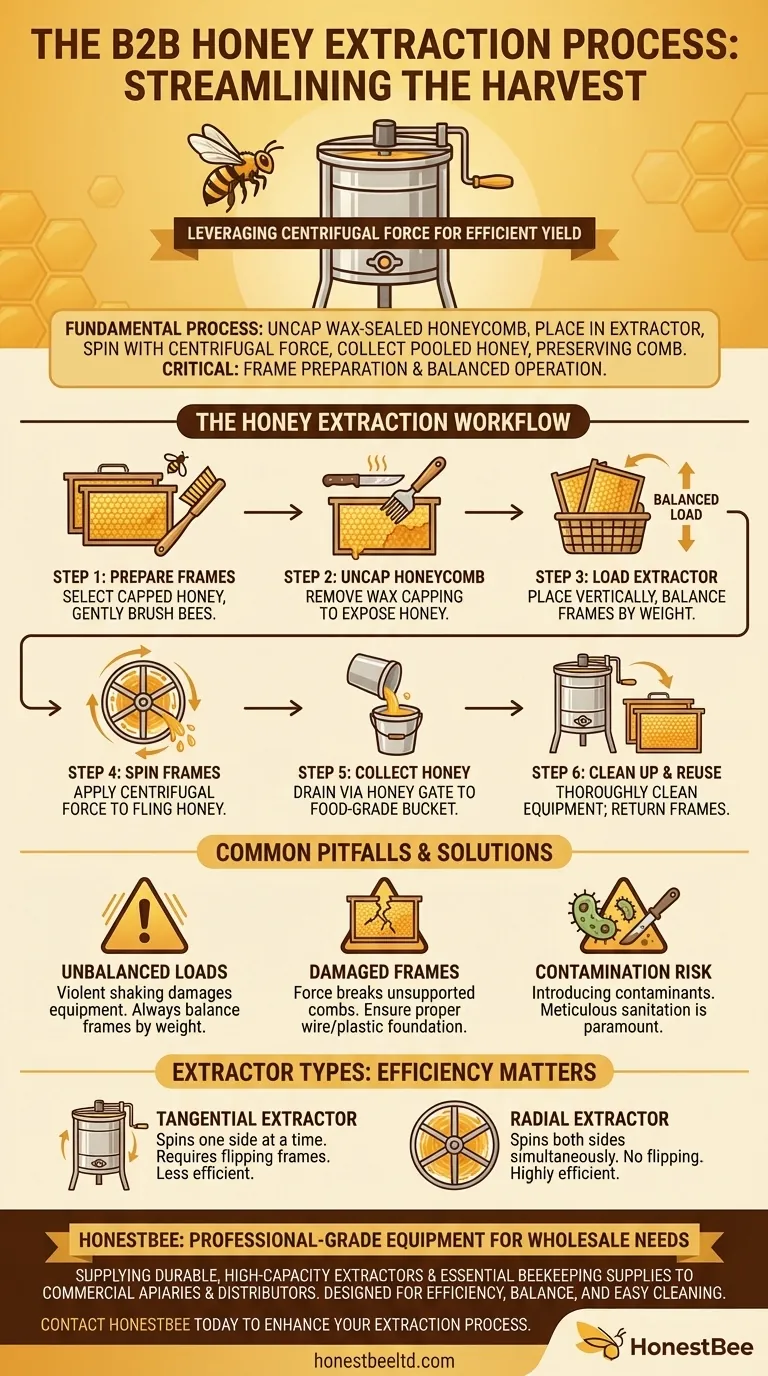

The fundamental process for using a honey extractor is to uncap the wax-sealed honeycomb, place the frames inside the extractor, and use centrifugal force to spin the honey out. The extracted honey then pools at the bottom, where it is drained through a honey gate into a collection container. This mechanical process is the modern standard for harvesting honey without destroying the honeycomb.

The core principle of a honey extractor is leveraging centrifugal force to separate honey from the comb. However, a successful and efficient harvest depends less on the spinning itself and more on the meticulous preparation of the frames and the proper, balanced operation of the machine.

The Honey Extraction Workflow: A Step-by-Step Guide

Successfully extracting honey is a systematic process that begins at the hive and ends with a clean extractor. Each step is critical for maximizing your yield and maintaining the health of your equipment and bees.

Step 1: Prepare the Frames

Before extraction can begin, you must select frames full of capped honey from the hive. Capped honey indicates the bees have finished ripening it, reducing the water content to the ideal level.

Use a bee brush to gently remove any lingering bees from the frames. This ensures no bees are harmed during the process and keeps your honey clean.

Step 2: Uncap the Honeycomb

Bees seal each cell of finished honey with a thin layer of wax. This wax capping must be removed to allow the honey to escape during extraction.

Use a heated knife or a specialized uncapping fork to carefully slice or scrape off this wax layer, exposing the liquid honey within the cells.

Step 3: Load the Extractor

Place the uncapped frames vertically into the baskets or slots inside the extractor.

It is critical to create a balanced load. Place frames of similar weight directly opposite each other to prevent the extractor from shaking violently during operation, which can damage the machine or the frames.

Step 4: Spin the Frames

Once the frames are securely in place, begin spinning the extractor. This can be done with a manual crank or an electric motor.

The spinning action creates centrifugal force, which flings the liquid honey out of the uncapped cells. The honey runs down the interior walls of the extractor drum.

Step 5: Collect the Honey

As the honey pools at the bottom of the extractor, open the honey gate or spigot to let it flow into a clean, food-grade bucket.

Do not let the honey level rise so high that it touches the rotating frames, as this will prevent the extractor from spinning at an effective speed.

Step 6: Clean Up and Reuse

After all the honey has been collected, the empty frames can be returned to the hive. The bees will clean them and begin refilling them with new honey.

Thoroughly clean the extractor immediately after use. Proper sanitation is essential for producing high-quality honey and preventing the spread of diseases between your hives.

Common Pitfalls and How to Avoid Them

While the process is straightforward, several common mistakes can lead to damaged equipment, lost honey, or compromised quality. Understanding these potential issues is key to a smooth harvest.

Unbalanced Loads

An unbalanced extractor is the most common operational error. The violent shaking can permanently damage the extractor's bearings and structure. Always take the time to balance the frames by weight before you start spinning.

Damaged Frames

Do not use frames that lack proper wire or plastic foundation support. The immense force generated during extraction can easily cause these unsupported combs to break apart, creating a significant mess and resulting in a total loss of that frame.

Inefficient Extraction

The type of extractor impacts the process. Tangential extractors spin honey from one side of the frame at a time and require you to stop, flip the frames, and spin again. Radial extractors are more efficient, extracting honey from both sides simultaneously.

Contamination Risk

Cleanliness cannot be overstated. Using unclean tools, buckets, or failing to properly sanitize the extractor after use can introduce bacteria and contaminants into your honey and potentially spread disease back to your hives.

Making the Right Choice for Your Goal

Your approach to extraction should align with your priorities, whether they are speed, equipment care, or the absolute highest quality product.

- If your primary focus is efficiency: Choose a radial extractor, which eliminates the need to flip frames mid-process and significantly speeds up your workflow.

- If your primary focus is equipment longevity: Always ensure your extractor is on level ground and that every load of frames is carefully balanced by weight.

- If your primary focus is honey quality and hive health: Meticulous sanitation is paramount. Clean every piece of equipment before and after extraction to ensure a pure product and prevent disease.

By treating honey extraction as a careful and deliberate process, you ensure a successful harvest and the continued health of your bees.

Summary Table:

| Step | Key Action | Critical Detail |

|---|---|---|

| 1. Prepare Frames | Select capped honey frames | Use a bee brush to gently remove bees |

| 2. Uncap Comb | Remove wax cappings | Use a heated knife or uncapping fork |

| 3. Load Extractor | Place frames in the extractor | Balance frames by weight to prevent shaking |

| 4. Spin Frames | Operate the extractor | Centrifugal force flings honey from the comb |

| 5. Collect Honey | Drain honey via the honey gate | Use a clean, food-grade bucket for collection |

| 6. Clean Up | Clean the extractor and return frames | Sanitation is key for hive health and honey quality |

Ready to streamline your honey harvest with professional-grade equipment?

HONESTBEE supplies durable, high-capacity honey extractors and essential beekeeping supplies to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations. Our equipment is designed for efficiency, balance, and easy cleaning to protect your investment and maximize your yield.

Contact HONESTBEE today to discuss your wholesale needs and discover how our solutions can enhance your extraction process.

Visual Guide

Related Products

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What are the benefits of using a centrifugal honey extractor? Boost Efficiency and Preserve Your Beehive's Energy

- What are the core advantages of centrifugal automatic honey extractors? Maximize Yield and Preserve Your Honeycomb

- How are weighing sensors and centrifugal honey extractors utilized for yield accuracy? Master Precision in Production

- What is the step-by-step guide for honey extraction with a centrifuge? Maximize Efficiency with Ease

- What are the technical contributions of Centrifugal Honey Extractors? Maximize Harvest Efficiency & Reuse Your Combs