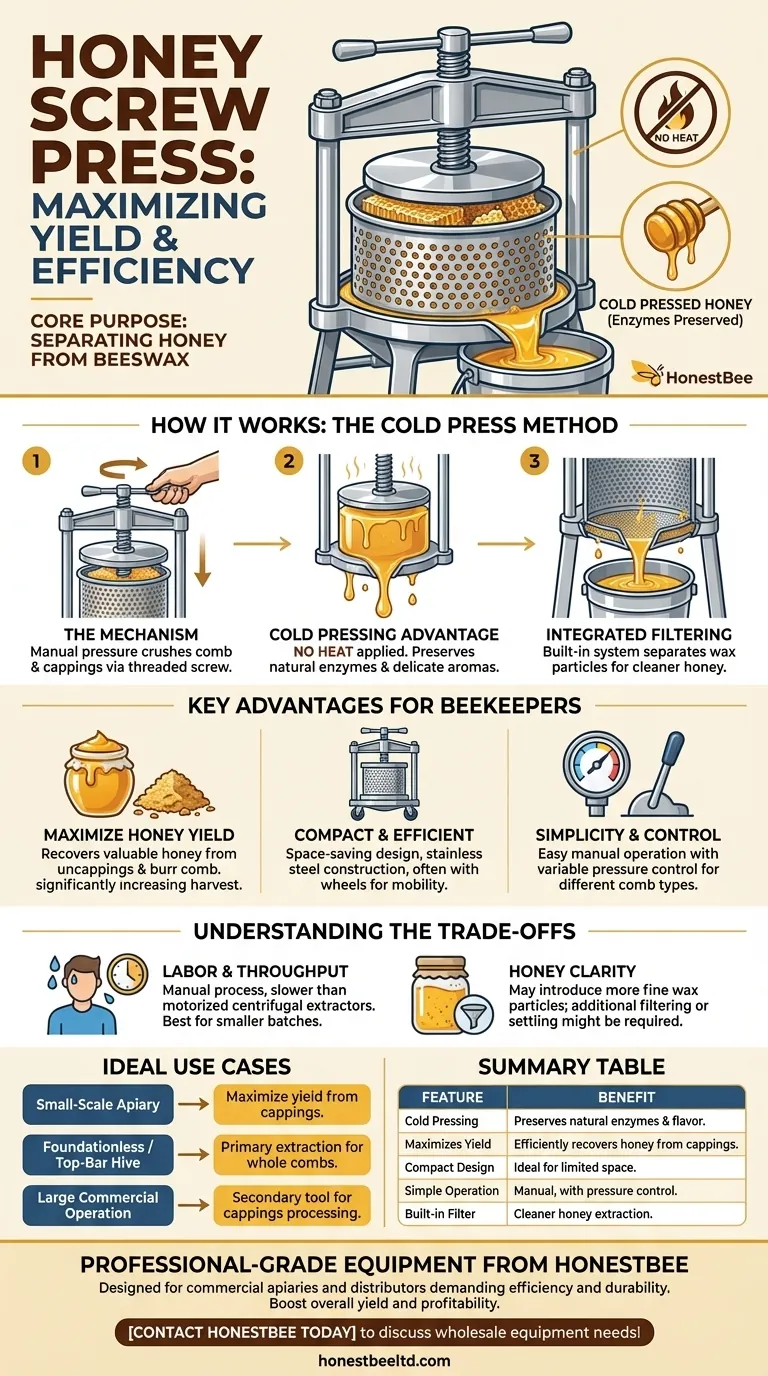

At its core, a honey screw press is a specialized tool designed for one primary function. It efficiently separates liquid honey from beeswax by crushing wax cappings or raw honeycomb using a cold pressing method. This allows beekeepers to reclaim valuable honey that would otherwise be difficult to extract.

The fundamental purpose of a screw press is to maximize your honey yield. It provides a simple, mechanical way to extract honey from comb and cappings without using heat, which is ideal for small-scale operations focused on quality.

How a Honey Press Works

A honey press, sometimes called a comb crusher, relies on a straightforward and effective mechanical process. Understanding this process highlights its value in the honey extraction workflow.

The Core Mechanism

The device uses a threaded screw to drive a pressing plate downward. Beekeepers load raw honeycomb or wax cappings into the press's perforated basket.

By rotating the handle clockwise, the plate applies immense, gradual pressure, crushing the comb and forcing the liquid honey out through the perforations.

The Cold Pressing Advantage

This entire process is mechanical and does not require heat. Cold pressing is crucial for preserving the natural enzymes, delicate aromas, and beneficial properties of the honey, resulting in a high-quality final product.

The extracted honey flows out of the press and is collected in a suitable container placed underneath. The remaining compressed beeswax, now much drier, is removed from the basket.

Built-in Filtering

Many modern honey presses include an integrated filtering system. As the honey is extracted, it passes through this filter, which helps separate it from beeswax particles and other impurities, producing cleaner honey that is ready for bottling.

Key Advantages for Beekeepers

While centrifugal extractors are common for standard frames, a screw press offers unique benefits, particularly for small-scale or specialized beekeeping.

Maximizing Honey Yield

The most significant advantage is its ability to process uncappings and burr comb. After slicing the wax caps off frames for extraction, those cappings are still full of honey. A screw press effortlessly recovers this honey, significantly increasing the total yield from a harvest.

Compact and Efficient Design

These presses are typically made from high-quality, acid-resistant stainless steel. Their compact design requires minimal space, making them perfect for small enterprises or hobbyists with limited room. Many are also equipped with wheels for easy transport.

Simplicity and Control

A screw press is simple and easy to operate. Furthermore, features like variable pressure control allow the user to customize the extraction process based on the type of comb, ensuring maximum efficiency without damaging the equipment.

Understanding the Trade-offs

While highly effective, a screw press is not the ideal solution for every situation. Objectivity requires acknowledging its limitations.

Labor and Throughput

The process is entirely manual and requires physical effort to turn the screw. Compared to a motorized centrifugal extractor, it is slower and less suitable for processing hundreds of frames in a large commercial operation.

Honey Clarity

Because a press works by crushing the entire comb structure, it can introduce more fine wax particles into the honey than centrifugal extraction. While filters help, the resulting honey may require additional settling time or secondary filtering to achieve perfect clarity.

Making the Right Choice for Your Goal

Deciding whether to invest in a honey screw press depends entirely on your specific beekeeping goals and methods.

- If your primary focus is maximizing yield from a small-scale apiary: A screw press is an invaluable tool for efficiently processing wax cappings and reclaiming otherwise lost honey.

- If you are a foundationless or top-bar hive beekeeper: A press is an essential piece of equipment, as your primary method of extraction involves crushing whole combs.

- If your primary focus is processing large volumes of standard frames quickly: A centrifugal extractor remains the more efficient primary tool, with a press serving as a secondary device for cappings.

Ultimately, a honey screw press empowers beekeepers to ensure no part of their hard-earned harvest goes to waste.

Summary Table:

| Feature | Benefit |

|---|---|

| Cold Pressing | Preserves honey's natural enzymes and flavor. |

| Maximizes Yield | Efficiently recovers honey from cappings and comb. |

| Compact Design | Ideal for small operations with limited space. |

| Simple Operation | Manual, mechanical process with variable pressure control. |

| Built-in Filter | Helps separate honey from wax particles for cleaner extraction. |

Maximize your honey harvest with professional-grade equipment from HONESTBEE.

Our honey screw presses are designed for commercial apiaries and distributors who demand efficiency and durability. By reclaiming honey from every wax capping, you significantly boost your overall yield and profitability.

We supply high-quality, stainless steel beekeeping supplies through wholesale-focused operations. Let us help you equip your operation for maximum success.

Contact HONESTBEE today to discuss your wholesale equipment needs!

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- How does the honey screw press operate? A Guide to Maximizing Honey Yield from Cappings

- How does a Wax Screw Press separate honey from wax? Maximize Your Honey Yield with Mechanical Efficiency

- What are the product advantages of honey pressing vs centrifugal extraction? Unlock Superior Artisanal Quality

- What is the 'crush & strain' method for harvesting honey? The Ultimate Low-Cost Guide to Manual Extraction

- What is the procedure for pressing honey? A Simple, Low-Cost Method for Small-Scale Beekeepers

- Is it possible to separate beeswax from honey without specialized equipment? Simple Low-Tech Separation Guide

- How does the honey separation and pressing process work in the Wax Screw Presses set? Maximize Honey Yield from Cappings

- What is the correct procedure for operating a honey press? Mastering the Art of Gradual Extraction