At its core, a settling tank is a basin used to separate suspended solids from a liquid—most commonly water—through the simple and reliable process of gravity. The primary goal is to slow the liquid's flow down dramatically, creating a calm environment where denser particles can naturally sink to the bottom for removal.

The effectiveness of a settling tank is not determined by its size alone, but by its ability to minimize water turbulence. The design of the tank's inlet and outlet zones is therefore the most critical factor in achieving clear water.

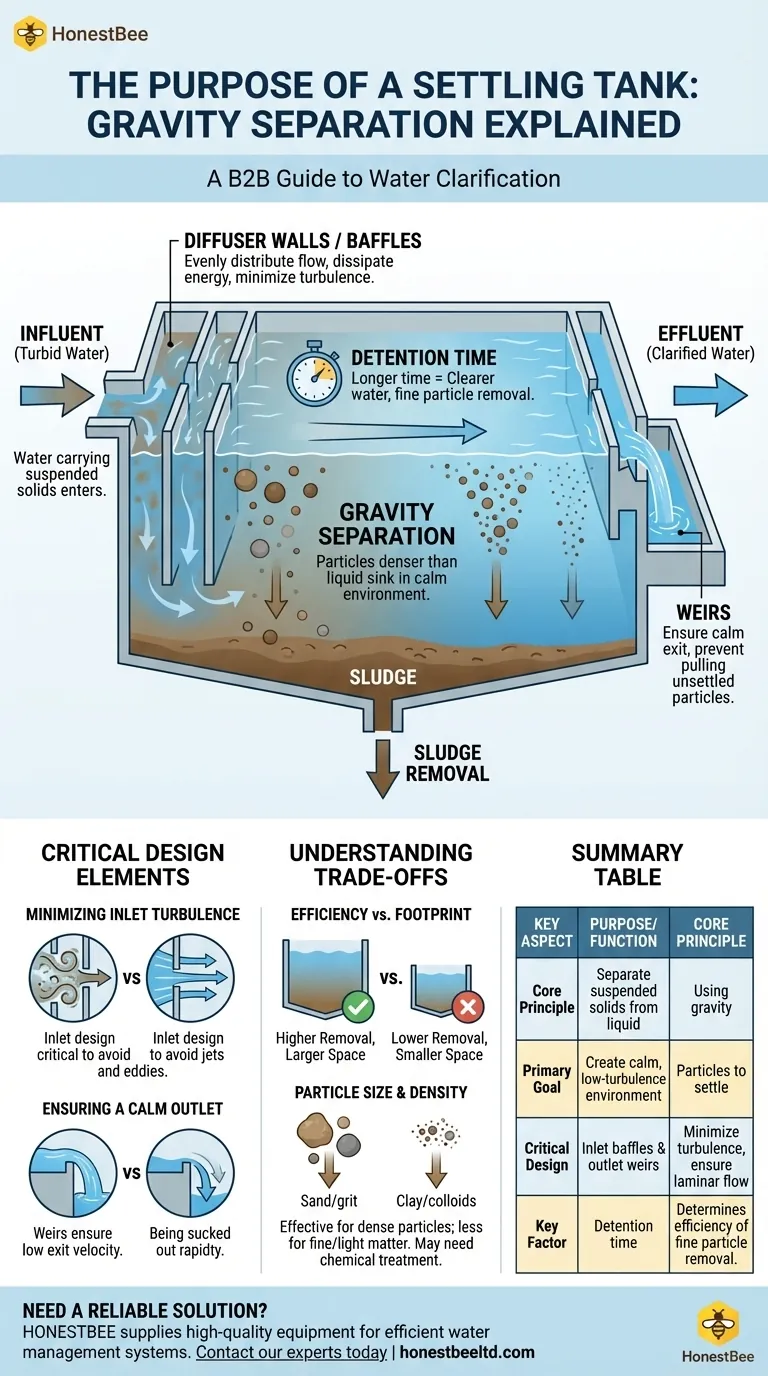

The Core Principle: Separation by Gravity

The entire function of a settling tank, also known as a clarifier or sedimentation basin, relies on a fundamental law of physics: particles that are denser than the liquid they are suspended in will sink over time if the liquid is sufficiently still.

How It Works

Influent, or water carrying suspended solids, enters the tank. The tank's large volume drastically reduces the velocity of the water, dissipating its energy.

This calm, low-velocity environment gives gravity the time it needs to act upon the solid particles. As they settle, they accumulate at the bottom of the tank as a layer of sludge, which can then be removed.

The Importance of Detention Time

Detention time refers to the average amount of time a water particle spends inside the tank. A longer detention time provides a greater opportunity for fine or less-dense particles to complete their journey to the bottom of the tank, resulting in clearer effluent.

Critical Design Elements for Effective Settling

A settling tank is more than just a large container. Its performance hinges on sophisticated hydraulic design meant to create ideal settling conditions from the moment water enters to the moment it leaves.

Minimizing Inlet Turbulence

The inlet zone is a primary point where settling can be disrupted. If water enters the tank too quickly, it creates jets and eddies that churn the water and prevent particles from settling.

To counter this, tanks use baffles or diffuser walls at the entrance. These structures evenly distribute the incoming flow across the tank's cross-section, dissipating energy and establishing a stable, slow-moving flow pattern known as "laminar flow."

Ensuring a Calm Outlet

The outlet zone is equally critical. As the clarified water exits, it must be collected without disturbing the settled sludge or pulling unsettled particles along with it.

This is typically achieved using weirs, which are long barriers with a crest set at a specific water level. Water gently overflows the weir over a very wide area, ensuring the exit velocity is extremely low and does not create currents that reach the bottom of the tank.

Understanding the Trade-offs

While the concept is simple, implementing a settling tank involves balancing competing factors. There is no single perfect design, only a design that is optimal for a specific application.

Efficiency vs. Footprint

A larger tank with a longer detention time will almost always remove more solids. However, this comes with a significantly higher construction cost and a larger physical footprint, which can be a major constraint.

Particle Size and Density

Gravity settling is highly effective for large, dense particles like sand and grit. It is far less effective for very fine, colloidal particles (like clay) or low-density organic matter.

For these challenging particles, settling may be too slow to be practical. In these cases, settling tanks are often preceded by chemical treatment processes, such as coagulation and flocculation, which clump small particles together into larger, heavier "flocs" that settle much more quickly.

Making the Right Choice for Your Goal

When designing or evaluating a sedimentation process, your primary objective will dictate your focus.

- If your primary focus is maximum purity: You must prioritize a design with sufficient detention time and highly engineered inlet and outlet zones to minimize turbulence.

- If your primary focus is cost efficiency: You may choose a smaller tank and accept lower removal efficiency, or invest in chemical pre-treatment to enhance the performance of a smaller basin.

- If your primary focus is treating water with variable solids: You need a robust design with well-placed baffles that can manage turbulence even as flow rates and solids loading change.

Ultimately, the settling tank leverages a simple force of nature to achieve the foundational goal of water clarification.

Summary Table:

| Key Aspect | Purpose/Function |

|---|---|

| Core Principle | Separate suspended solids from liquid using gravity. |

| Primary Goal | Create calm, low-turbulence environment for particles to settle. |

| Critical Design | Inlet baffles & outlet weirs to minimize turbulence and ensure laminar flow. |

| Key Factor | Detention time determines the efficiency of fine particle removal. |

Need a reliable solution for your water clarification process?

HONESTBEE supplies high-quality beekeeping and agricultural equipment, including components essential for building efficient water management systems. Our durable supplies are trusted by commercial apiaries and distributors for their reliability and performance.

Whether you're designing a new system or upgrading an existing one, we can provide the robust equipment you need. Contact our experts today to discuss how we can support your operation with dependable wholesale supplies.

Visual Guide

Related Products

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Stainless Steel Uncapping Tank with Stand and Strainer

- Stainless Steel Honey Storage Tank with Lid for Honey

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Professional Honey Storage Tank with Agitation System

People Also Ask

- Can we store honey in stainless steel container? A Guide to Safe, Bulk Honey Storage

- How long should honey settle in settling tanks? The 48-Hour Rule for Perfect Clarity

- What are the primary functions of a double uncapping tank? Maximize Honey Yield and Wax Collection

- How does a honey maturator or settling tank contribute to the quality of the final honey product? Enhance Clarity Now

- What does a honey settling tank do? The Key to Clean, Professional-Quality Honey

- What role do decanting tanks play in the honey refining process? Achieve Superior Clarity for Commercial Success

- What should be done with wax cappings after uncapping? A Two-Stage Guide to Maximize Your Harvest

- What is the primary function of a stainless steel honey uncapping table? Optimize Your Honey Extraction Pretreatment