In honey packaging, induction sealing serves a critical dual purpose. It is a non-contact process that creates a hermetic, airtight barrier by heating a foil liner inside the cap, bonding it to the rim of the jar. This seal simultaneously protects the honey's quality and provides clear, undeniable evidence of tampering.

While a simple cap can close a honey jar, an induction seal fundamentally secures it. It transforms the package into a tamper-evident vault that preserves the honey's natural purity and prevents leaks from the farm to the pantry.

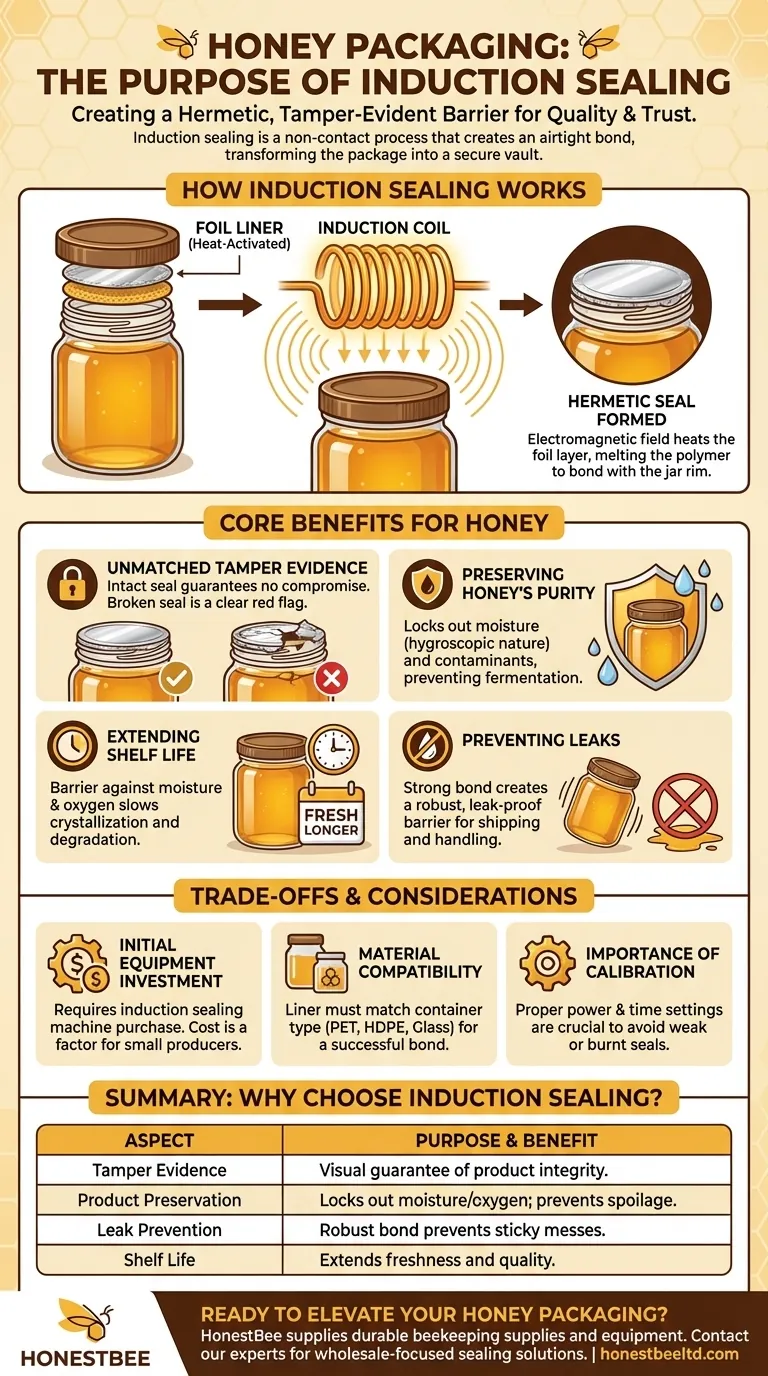

How Induction Sealing Works

Induction sealing is an elegant and reliable process that happens after the honey jar has been filled and capped. It relies on the principles of electromagnetism to create a perfect seal without direct heat contact to the container itself.

The Key Components: Liner and Cap

The magic lies in a multi-layered liner inside the cap. This liner typically consists of a layer of foil, a heat-activated polymer film, and a backing material like pulpboard that stays inside the cap after the seal is made.

The Role of the Electromagnetic Field

The capped jar passes under an induction coil, which generates a high-frequency electromagnetic field. This field is the "non-contact" part of the process; it passes harmlessly through the plastic cap and glass or plastic jar.

Creating the Hermetic Seal

The electromagnetic field induces an electrical current exclusively in the foil layer of the liner, causing it to heat up rapidly. This heat melts the polymer film, which then fuses to the rim of the jar, creating an airtight, or hermetic, seal.

The Core Benefits for Honey Packaging

Using an induction seal for honey is not just a packaging trend; it directly addresses the unique chemical properties of honey and the expectations of the modern consumer.

Unmatched Tamper Evidence

This is the most visible benefit. A perfectly intact foil seal guarantees to the customer that the product has not been opened or compromised since it left the producer. A broken or missing seal is an immediate red flag, building immense brand trust.

Preserving Honey's Purity

Honey is hygroscopic, meaning it naturally absorbs moisture from the air. An unsealed or poorly sealed jar can lead to the honey absorbing water, which can dilute its flavor, alter its texture, and potentially lead to fermentation. The hermetic seal locks out moisture and other airborne contaminants.

Extending Shelf Life

By creating a barrier against both moisture and oxygen, an induction seal helps prevent the natural process of crystallization and degradation. This keeps the honey in its ideal state for a much longer period on the shelf and in the customer's home.

Preventing Leaks

Honey is viscous and notoriously sticky. The strong bond created by induction sealing provides a robust, leak-proof barrier that is essential during shipping, handling, and stocking on retail shelves. This prevents product loss and messy cleanup.

Understanding the Trade-offs and Considerations

While highly effective, induction sealing is a deliberate choice that comes with specific requirements.

Initial Equipment Investment

Implementing this process requires purchasing an induction sealing machine. The cost can be a significant consideration for small-scale or startup honey producers compared to simply using standard caps.

Material Compatibility

Success depends on using the correct materials. The liner must be specifically designed for the container type (e.g., PET plastic, HDPE plastic, or glass). Using an incompatible liner and jar combination will result in a weak seal or no seal at all.

The Importance of Calibration

The induction sealer must be properly calibrated. Too little power or time will result in a weak, incomplete seal. Too much power can overheat the liner, potentially burning the seal, damaging the cap, or even scorching the honey at the top of the jar.

Making the Right Choice for Your Honey

Choosing to use induction sealing depends on your production scale, distribution channels, and brand positioning.

- If your primary focus is retail distribution and brand trust: An induction seal is non-negotiable. It provides the tamper evidence and leak protection that retailers and consumers demand.

- If your primary focus is maximizing product quality and shelf life: The hermetic seal is the single most effective way to protect honey from moisture absorption and degradation over time.

- If you are a small producer selling at local markets: While the equipment cost is a factor, providing a sealed product signals a high level of professionalism and commitment to safety that can set you apart.

Ultimately, adopting induction sealing is a definitive step in presenting your honey as a safe, high-quality, and professionally packaged product.

Summary Table:

| Aspect | Purpose & Benefit |

|---|---|

| Tamper Evidence | Provides a clear, visual guarantee the product hasn't been opened or compromised. |

| Product Preservation | Creates a hermetic seal that locks out moisture and oxygen, preventing fermentation and crystallization. |

| Leak Prevention | Forms a strong bond to the jar rim, preventing sticky leaks during shipping and handling. |

| Shelf Life | Extends the honey's freshness and quality by protecting it from environmental contaminants. |

Ready to elevate your honey packaging with professional-grade sealing solutions?

HONESTBEE supplies the durable beekeeping supplies and equipment that commercial apiaries and distributors rely on for efficient, high-quality operations. We understand the critical need for packaging that protects your product and builds brand trust.

Contact our experts today to discuss how our wholesale-focused solutions can help you implement reliable induction sealing for your honey products.

Visual Guide

Related Products

- Handheld Induction Sealing Machine for Tamper Evident Packaging

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Automatic Continuous Heat Sealing Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- How do sealing packaging equipment and high-quality bottling consumables contribute to honey shelf life and quality?

- What is the function of semi-automatic heat shrink packaging machines in a glass jar reuse facility? Protect Your Inventory

- What is a 4-side seal in packaging? Achieve Unmatched Product Protection & Branding

- What is a sealing machine? Protect Your Product Quality and Brand Reputation

- What is the necessity of using industrial-grade plastic sealing bags? Ensure Honey Sample Integrity in Lab Testing

- What is a fin seal on a stick pack? Learn the Key Benefits for Your Packaging Line

- What defines a 3-side seal on a stick pack? Unlock the Benefits of Efficient Folded Packaging

- What advantages do vacuum sealing bags provide for the storage of dried bee pollen? Preserve Freshness and Potency