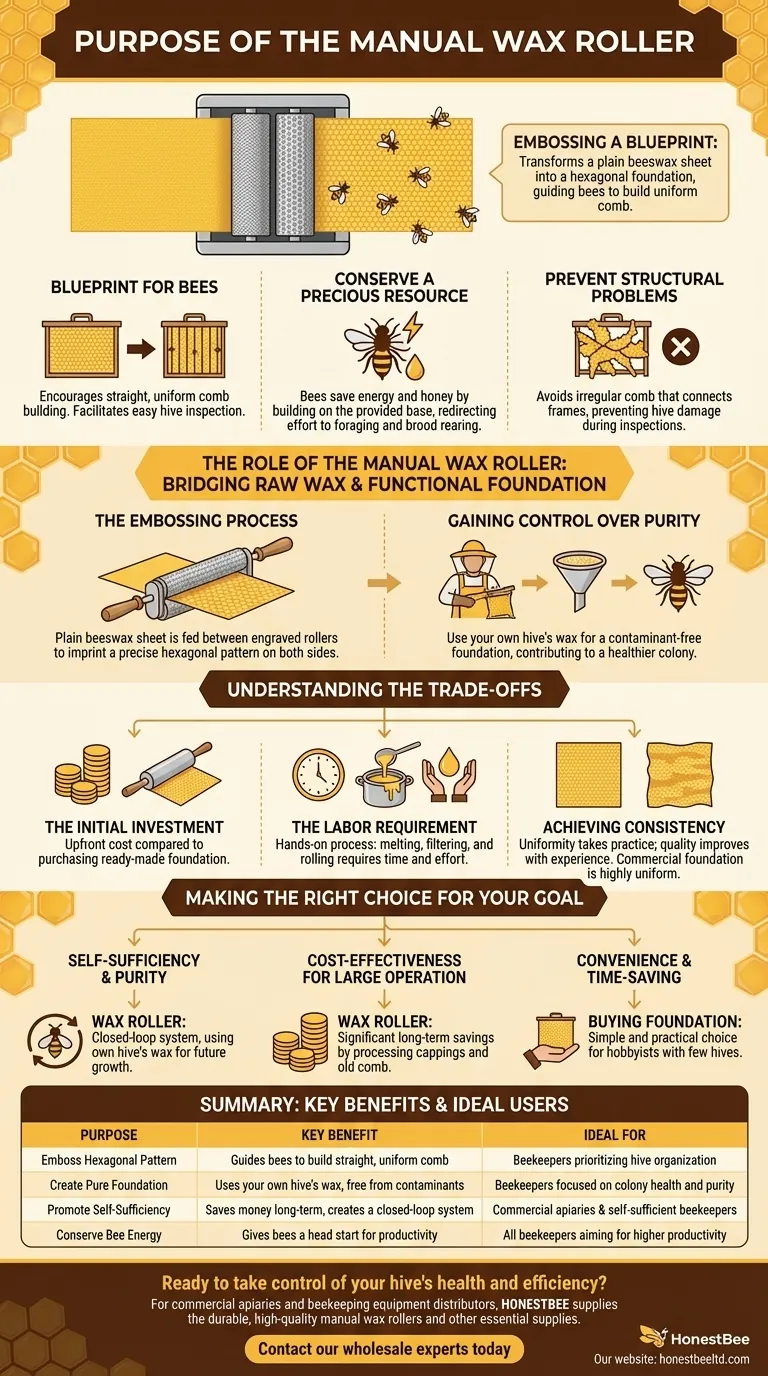

The primary purpose of a manual wax roller is to emboss a precise hexagonal cell pattern onto a plain sheet of beeswax. This process transforms a simple wax sheet into a "foundation," which serves as a guide for honeybees to build their comb within a hive frame.

A wax roller is a specialized tool that empowers beekeepers to create their own comb foundation from their hive's wax. This provides bees with a critical blueprint for building their home, saving them energy and ensuring a well-organized hive.

Why Beeswax Foundation is Essential

Beeswax foundation is a cornerstone of modern beekeeping. While bees can build comb without it, providing a patterned foundation offers significant advantages for the health and productivity of the colony.

A Blueprint for the Bees

Foundation gives bees a clear guide. The embossed hexagonal pattern encourages them to build straight, uniform combs within the confines of the frame.

This organized structure is crucial for the beekeeper. It allows for easy removal and inspection of frames without damaging the comb or harming the bees.

Conserving a Precious Resource

Bees produce wax from glands on their abdomens, a process that consumes a significant amount of energy and resources (honey).

By providing a foundation, the beekeeper gives the colony a head start. The bees can use the provided wax base and build upon it, conserving energy that can be redirected toward foraging, raising brood, and producing honey.

Preventing Structural Problems

Without a guide, bees may build "cross comb," which is comb that connects multiple frames or is built in irregular directions. This makes hive inspections nearly impossible and can lead to the comb being destroyed during an inspection.

The Role of the Manual Wax Roller

The manual wax roller is the tool that bridges the gap between raw beeswax and functional foundation sheets. It's a key component for any beekeeper aiming for self-sufficiency.

The Embossing Process

The tool itself consists of two rollers engraved with the hexagonal cell pattern. A smooth, thin sheet of beeswax is carefully fed between these rollers.

As the beekeeper turns the handle, the rollers press the pattern firmly into both sides of the sheet, creating the finished foundation.

Gaining Control Over Purity

One of the most significant advantages of making your own foundation is control over the material. You can use wax harvested directly from your own hives.

This ensures the foundation is free from contaminants or pesticides that can sometimes be found in commercially sourced wax, contributing to a healthier environment for your bees.

Understanding the Trade-offs

While creating your own foundation is rewarding, it's important to recognize the practical considerations involved. It is a hands-on process that requires more than just the roller itself.

The Initial Investment

A high-quality wax roller is a durable piece of equipment, but it represents an upfront cost compared to simply buying a box of foundation sheets.

The Labor Requirement

The process is not instant. It involves melting and filtering your raw beeswax, forming it into thin, plain sheets, and then carefully running each one through the roller. This requires time, space, and effort.

Achieving Consistency

Commercially produced foundation is highly uniform. Achieving that same level of consistency with a manual roller takes practice. The thickness and quality of your sheets will improve with experience.

Making the Right Choice for Your Goal

Deciding whether to invest in a manual wax roller depends entirely on your beekeeping philosophy and objectives.

- If your primary focus is self-sufficiency and purity: A wax roller is an invaluable tool for creating a closed-loop system, using wax from your own hives to support their future growth.

- If your primary focus is cost-effectiveness for a large operation: Processing your own cappings and old comb into new foundation can offer significant long-term savings over continually purchasing it.

- If your primary focus is convenience and time-saving: For the hobbyist with a few hives, the simplicity of purchasing ready-to-use foundation is often the most practical and efficient choice.

Ultimately, the manual wax roller is a tool that transforms a raw hive product into a critical blueprint for a healthy and productive colony.

Summary Table:

| Purpose | Key Benefit | Ideal For |

|---|---|---|

| Emboss Hexagonal Pattern | Guides bees to build straight, uniform comb | Beekeepers prioritizing hive organization |

| Create Pure Foundation | Uses your own hive's wax, free from contaminants | Beekeepers focused on colony health and purity |

| Promote Self-Sufficiency | Saves money long-term and creates a closed-loop system | Commercial apiaries and self-sufficient beekeepers |

| Conserve Bee Energy | Gives bees a head start, redirecting energy to foraging and honey production | All beekeepers aiming for higher productivity |

Ready to take control of your hive's health and efficiency?

For commercial apiaries and beekeeping equipment distributors, creating your own pure, cost-effective foundation is key to a thriving operation. HONESTBEE supplies the durable, high-quality manual wax rollers and other essential beekeeping supplies you need to build a self-sufficient and productive beekeeping business.

Contact our wholesale experts today to discuss your equipment needs and learn how we can support your success!

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

People Also Ask

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- What is the primary function of the manual honeycomb embossing machine? Gain Control Over Your Hive's Foundation

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency