In short, the honey hopper is the component that holds the bulk volume of honey before it is packaged. It's a conical-shaped reservoir, typically located at the top of the machine, designed to feed the filling station with a consistent, uninterrupted supply of product.

The honey hopper isn't just a simple container; it's the machine's buffer system. Its primary role is to decouple the bulk honey supply from the high-speed filling process, ensuring operational consistency and minimizing production downtime.

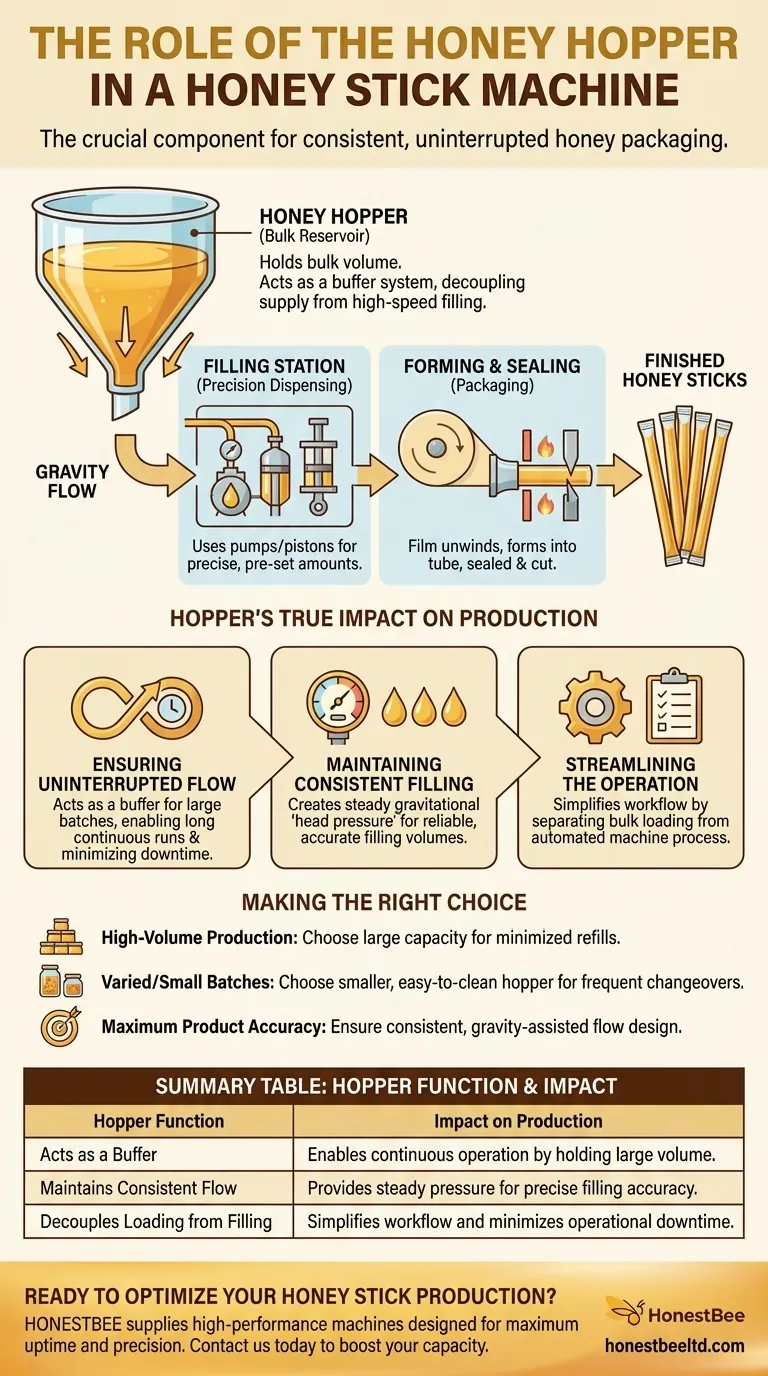

How the Hopper Fits into the Honey Stick Workflow

To fully appreciate the hopper's role, it helps to understand its place within the machine's entire process. Each component performs a distinct job in a carefully orchestrated sequence.

The Starting Point: The Honey Hopper

The entire packaging process begins here. The honey hopper acts as a reservoir, holding a large quantity of honey. Its conical shape uses gravity to ensure that the honey flows smoothly downwards towards the next stage.

Precision Dispensing: The Filling Station

Directly fed by the hopper, the filling station is responsible for accuracy. It uses pumps and pistons to draw a precise, pre-set amount of honey and dispense it into the packaging film. A steady supply from the hopper is critical for the filling station to function correctly.

Creating the Package: Forming and Sealing

While the honey is being prepared, an unwinding disk feeds a flat roll of packaging film into the machine. A forming tube then folds this flat film into the characteristic long, thin "stick" shape. As the honey is dispensed, sealing bars close and heat the film to create the top and bottom seals of each stick.

The Final Step: Separation

A sharp blade, often called the cutter, is located within the sealing bars. It makes a clean cut to separate each filled and sealed honey stick from the continuous roll of packaging, completing the process.

The Hopper's True Impact on Production

The hopper might seem like a passive component, but its design directly influences the machine's efficiency and reliability. Its importance goes far beyond simply holding honey.

Ensuring Uninterrupted Flow

The most critical function of the hopper is to act as a buffer. It allows an operator to load a large batch of honey at once, letting the machine run continuously for a long period without needing constant attention. Without it, the machine would stop every few moments for a refill.

Maintaining Consistent Filling

The volume of honey in the hopper creates consistent gravitational pressure, or "head pressure," on the filling station. This steady pressure helps the pumps and pistons operate more reliably, ensuring that each honey stick is filled with the same precise amount of product.

Streamlining the Entire Operation

By holding a large volume, the hopper simplifies the workflow. It creates a clear distinction between the bulk-loading task and the machine's automated operation, allowing for a more organized and efficient production environment.

Making the Right Choice for Your Goal

Understanding the hopper's function helps you evaluate a machine based on your specific production needs.

- If your primary focus is high-volume, continuous production: A large-capacity hopper is essential to minimize downtime from frequent refills.

- If your primary focus is producing varied, smaller batches: A smaller hopper that is easy to access and clean is more practical for frequent changeovers.

- If your primary focus is maximum product accuracy: A well-designed hopper that provides a consistent, gravity-assisted flow is critical for the filling station's precision.

Ultimately, the honey hopper is the key to a smooth, efficient, and reliable honey stick production line.

Summary Table:

| Hopper Function | Impact on Production |

|---|---|

| Acts as a Buffer | Enables continuous operation by holding a large volume of honey. |

| Maintains Consistent Flow | Provides steady gravity pressure for precise filling accuracy. |

| Decouples Loading from Filling | Simplifies workflow and minimizes operational downtime. |

Ready to Optimize Your Honey Stick Production?

A reliable honey hopper is the foundation of an efficient packaging line. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-performance, wholesale-focused honey stick machines designed for maximum uptime and precision.

Contact us today to discuss how our equipment can streamline your operation and boost your production capacity.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- How does a honey filling machine operate? Master Volumetric Displacement and Precision Filling

- How does honey-filling machinery enhance the market value of stingless bee honey? Scale Your Premium Honey Brand

- What role do automated honey filling lines play in improving product safety? Boost Competitiveness & Brand Trust

- What is the function of automatic honey filling machines? Transform Bulk Honey into High-Value Retail Assets

- What are some common types of honey packaging machines? Choose the Right One for Your Operation

- What types of liquids is the mini filling machine designed to bottle? Versatile High-Viscosity Solutions

- What are the technical advantages of using automated honey filling machinery? Optimize Safety and Scalability

- What are the core advantages of using high-precision honey-filling machines? Enhance Your Honey Processing Value Chain