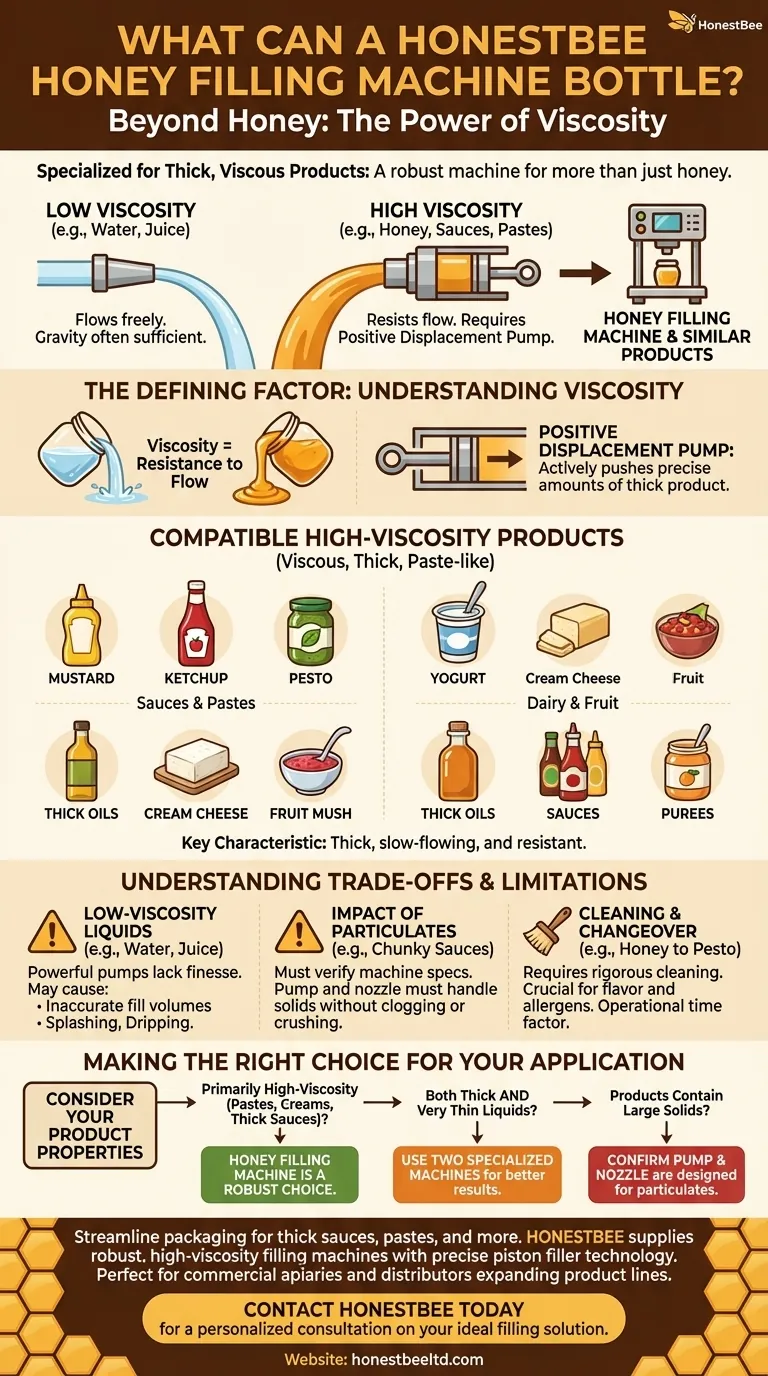

Beyond honey, a specialized filling machine can handle a wide range of thick, viscous products. These machines are engineered for substances that do not flow easily, making them suitable for bottling liquids such as mustard, ketchup, various dairy products, oil, sauces, pesto, and fruit mush. The common characteristic among all these products is their high viscosity.

The core principle is viscosity. A machine designed to pump thick, slow-moving honey is inherently capable of handling other high-viscosity liquids. However, this specialization means it is often unsuitable for thin, watery substances without significant adjustments or compromises.

The Defining Factor: Understanding Viscosity

What is Viscosity?

Viscosity is a measure of a fluid's resistance to flow. Think of the difference between pouring water and pouring honey from a jar.

Water has low viscosity and flows freely. Honey has high viscosity, moving slowly and resisting flow. Filling machines are specifically designed to handle a certain range of viscosities.

Why Honey Fillers are Different

Standard liquid fillers often rely on gravity. Honey fillers cannot; they must use a powerful mechanism, typically a piston filler or positive displacement pump, to actively push a precise amount of the thick product into the container.

This powerful, controlled pushing action is what makes the machine effective for honey. It also makes it perfectly suited for other products that share honey's thick, paste-like consistency.

Matching Products to the Machine

The list of compatible products all share this trait of high viscosity.

- Sauces & Pastes: Ketchup, mustard, and pesto are all thick and do not flow easily.

- Dairy & Fruit: Viscous dairy products like yogurt or cream cheese, as well as thick fruit mush or purées, have similar handling requirements to honey.

- Oils: While some oils are thin, thicker oils and emulsified products fit the profile of a honey filler.

Understanding the Trade-offs and Limitations

The Problem with Low-Viscosity Liquids

Using a honey filler for thin, watery liquids like juice or light syrups can be problematic. The powerful pump may lack the finesse for these products.

This can lead to inaccurate fill volumes, splashing, and dripping from the nozzle between cycles, as the thin liquid may leak past seals designed to hold back a thicker substance.

The Impact of Particulates

If your product contains solids—like a chunky pasta sauce or fruit preserves—you must verify the machine's specifications.

The pump mechanism and nozzle opening must be large enough to pass the particulates without clogging the system or crushing the ingredients. Not all viscous liquid fillers are designed to handle solids.

Cleaning and Product Changeover

Switching between products requires rigorous cleaning. The same components that make the machine powerful also create more surface area where thick products can stick.

Changing from a sweet product like honey to a savory one like pesto demands meticulous sanitation to prevent flavor contamination and manage potential allergens. This operational time is a critical factor to consider.

Making the Right Choice for Your Application

To ensure you are using the equipment effectively, consider the physical properties of your products.

- If your primary focus is high-viscosity liquids (pastes, creams, thick sauces): A honey filling machine is a versatile and robust choice for your product line.

- If you bottle both thick and very thin liquids: You will likely achieve better results with two specialized machines rather than compromising with one.

- If your products contain large solids: You must confirm that the filler's pump and nozzle are explicitly designed to handle particulates of that size.

Understanding your product's physical properties is the key to maximizing the utility and return on your equipment investment.

Summary Table:

| Compatible High-Viscosity Liquids | Key Characteristic |

|---|---|

| Mustard, Ketchup, Pesto | Thick sauces and pastes |

| Yogurt, Cream Cheese | Viscous dairy products |

| Thick Oils, Fruit Purées | Slow-flowing liquids |

| Incompatible Liquids | Reason |

| Water, Juice, Light Syrups | Too thin; causes splashing and inaccuracy |

Streamline your packaging for thick sauces, pastes, and more.

HONESTBEE supplies robust, high-viscosity filling machines perfect for commercial apiaries and beekeeping equipment distributors looking to expand their product lines. Our piston filler and positive displacement pump technology ensures precise, efficient bottling for your entire range of viscous products.

Contact HONESTBEE today for a personalized consultation on the ideal filling solution for your operation.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- How do industrial honey-filling machines address infrastructure deficiencies? Standardize Your Logistics & Branding

- How do automatic honey-filling machines ensure market competitiveness? Elevate Your Brand and Profitability

- Why is high-cleanliness honey extraction and filling machinery essential for atmospheric metal tracing? Guide to Data Integrity

- What is the importance of professional honey filling and storage equipment for maintaining honey quality and potency?

- Which method is used for liquid filling? Find the Perfect Solution for Your Product

- In what ways do automatic filling machines impact labor costs? Cut Expenses and Boost Efficiency

- How do automated honey filling machines ensure product quality and safety? Optimize Your Packaging Standards

- What are the advantages of integrating professional-grade honey-filling machines? Scaling Your Production for Growth