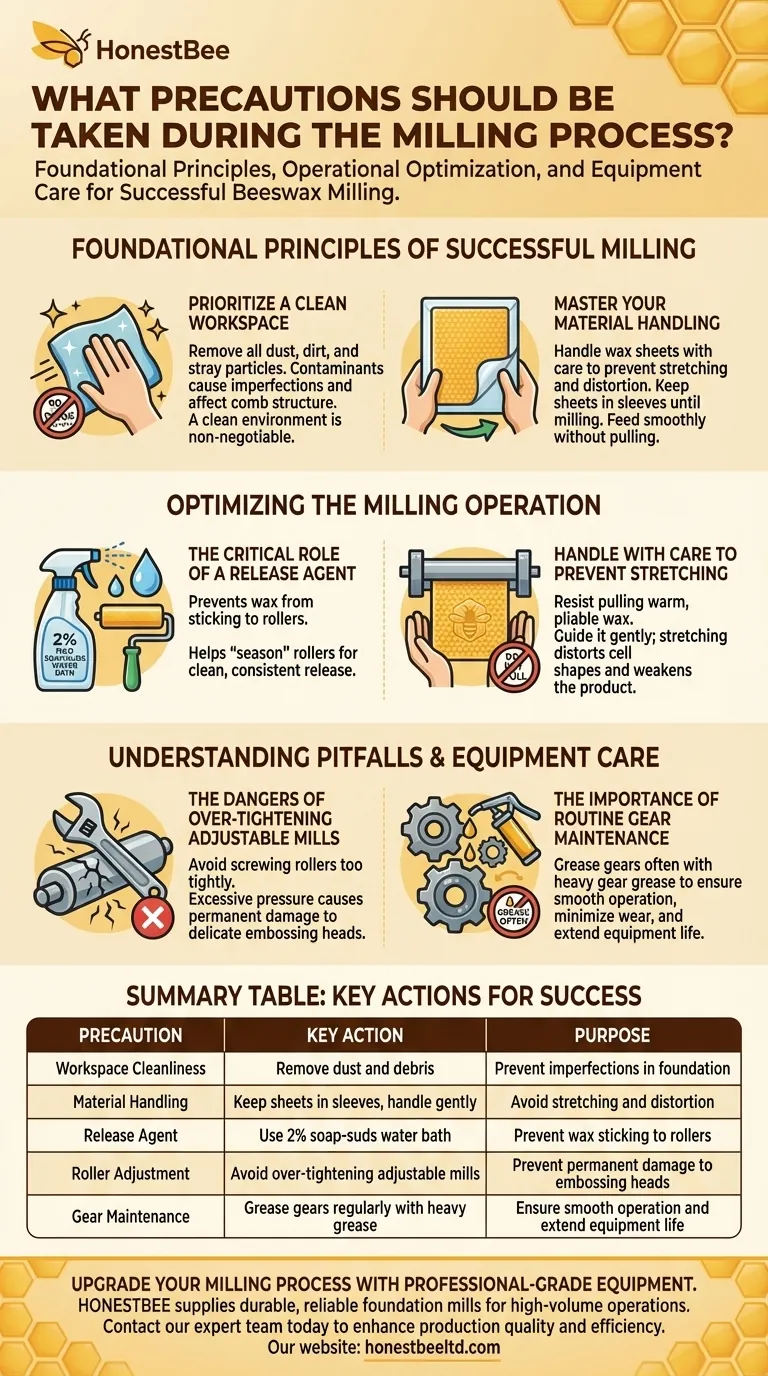

To ensure a successful milling process, you must maintain a clean workspace, lubricate the mill's gears, use a release agent to prevent sticking, and handle the wax sheets carefully to avoid distortion. For adjustable mills, it is especially critical to avoid over-tightening the rollers, which can cause permanent damage to the equipment.

The quality of your beeswax foundation and the lifespan of your mill are not determined by a single action, but by a disciplined approach. Success hinges on a balance between meticulous preparation, precise operational technique, and vigilant equipment maintenance.

Foundational Principles of Successful Milling

Before a single sheet of wax enters the mill, your preparation sets the stage for the final outcome. Overlooking these initial steps is the most common source of poor-quality foundation and unnecessary frustration.

Prioritize a Clean Workspace

Debris is the enemy of uniform foundation. Any dust, dirt, or stray particles in your milling area can easily adhere to the warm wax sheets.

These contaminants will be pressed directly into your foundation, creating imperfections that can affect the structural integrity of the comb. A clean environment is a non-negotiable first step.

Master Your Material Handling

Wax sheets are delicate and prone to distortion. To prevent stretching and protect the intended cell size, consider keeping the sheets in a plastic sleeve until you are ready to mill them.

Handle each sheet with care throughout the process. The goal is to feed the wax smoothly into the mill without pulling or warping it.

Optimizing the Milling Operation

Once the wax meets the machine, your technique becomes paramount. The interaction between the wax, the rollers, and the release agent determines the success of the embossing process.

The Critical Role of a Release Agent

To prevent the wax from sticking to the mill's rollers, a lubricating release agent is essential. The standard solution is a water bath containing approximately 2% mild, biodegradable soap-suds.

This solution not only prevents sticking but also helps "season" the rollers, ensuring a clean and consistent release of the foundation sheet with every pass.

Handle with Care to Prevent Stretching

As the embossed foundation exits the mill, resist the urge to pull on it. Stretching the warm, pliable wax will distort the cell shapes and create a weak, uneven final product.

Allow the machine to dictate the pace and support the foundation sheet as it emerges, guiding it gently rather than forcing it.

Understanding the Pitfalls and Equipment Care

A foundation mill is a precision instrument. Misuse or neglect will not only ruin your product but can also lead to costly and irreparable damage to the machine itself.

The Dangers of Over-tightening Adjustable Mills

If you are using a mill with adjustable rollers, you must avoid the temptation to screw them down too tightly. Applying excessive pressure will not create a deeper impression.

Instead, it can permanently damage the delicate embossing heads on the rollers, ruining the mill's ability to produce a correct cell pattern. Always adjust pressure incrementally and with extreme caution.

The Importance of Routine Gear Maintenance

The gears of your mill are under significant strain. To ensure they run smoothly and to minimize wear, they must be greased often with a heavy gear grease.

Proper lubrication maintains tight and efficient operation, extending the life of your equipment and preventing the jerky movements that can mar the foundation.

Setting Expectations: Pre-set vs. Adjustable Mills

Understand the equipment you are using. A pre-set spaced foundation mill, for example, is calibrated to produce a specific thickness, typically yielding around seven sheets of foundation per pound of wax. An adjustable mill offers more flexibility but requires more skill to operate without causing damage.

Making the Right Choice for Your Goal

Your specific precautions should align with your primary objective. Whether you are focused on quality, efficiency, or equipment longevity, a disciplined approach is key.

- If your primary focus is producing high-quality foundation: Prioritize a perfectly clean workspace and careful handling to prevent stretching or contamination.

- If your primary focus is maximizing equipment lifespan: Emphasize routine gear lubrication and be extremely cautious to never over-tighten adjustable rollers.

- If your primary focus is process efficiency: Ensure your soap-suds release agent is prepared in advance and your workflow is organized to move sheets smoothly.

By treating your mill as the precision instrument it is, you can consistently turn raw beeswax into perfect, high-quality foundation.

Summary Table:

| Precaution | Key Action | Purpose |

|---|---|---|

| Workspace Cleanliness | Remove all dust and debris | Prevent imperfections in foundation |

| Material Handling | Keep sheets in sleeves, handle gently | Avoid stretching and distortion |

| Release Agent | Use 2% soap-suds water bath | Prevent wax sticking to rollers |

| Roller Adjustment | Avoid over-tightening adjustable mills | Prevent permanent damage to embossing heads |

| Gear Maintenance | Grease gears regularly with heavy grease | Ensure smooth operation and extend equipment life |

Upgrade Your Milling Process with Professional-Grade Equipment

Producing perfect beeswax foundation requires precision equipment and expert knowledge. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, reliable foundation mills and accessories designed for high-volume operations. Our wholesale-focused approach ensures you get professional-grade equipment at competitive prices.

Contact our expert team today to discuss how our foundation mills and beekeeping supplies can enhance your production quality, increase efficiency, and extend your equipment's lifespan. Let us help you achieve consistent, flawless results batch after batch.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What equipment is needed to make beeswax foundation? A Guide to DIY Wax Sheet Production

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- What additional preparation is needed for the work area when making beeswax sheets? Set Up a Professional Production Line

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction