Before using any top feeder, your inspection must focus on two critical components: the hardware cloth screen that separates the bees from the syrup reservoir and the inner cover that seals the top. These elements work together to ensure bees can access the syrup only from the intended channel, preventing drowning and discouraging pests or robber bees.

A top feeder is only as good as it is secure. The fundamental goal of your pre-use inspection is to confirm the feeder is 'bee-tight'—creating a closed system where syrup is accessible only through the designated feeding channel, eliminating any risk of bees getting trapped in the main reservoir.

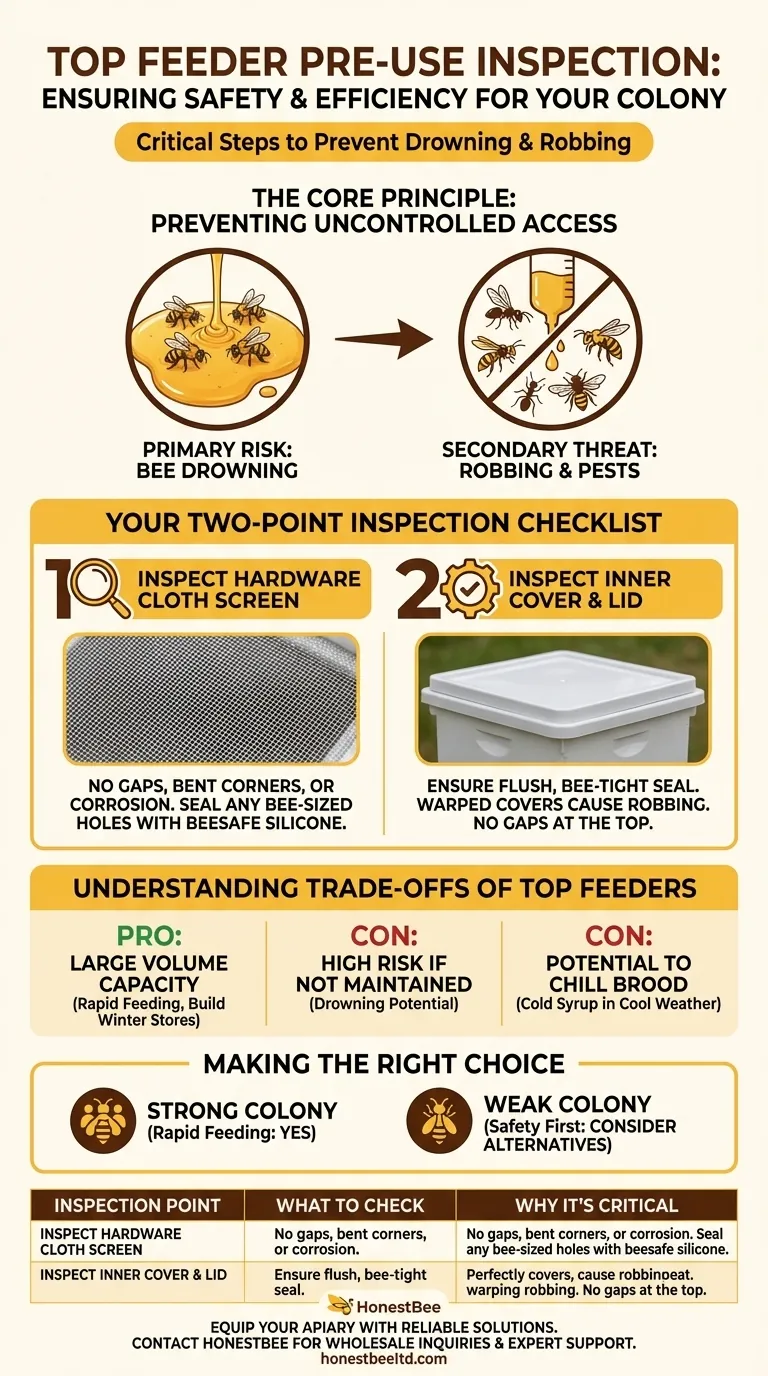

The Core Principle: Preventing Uncontrolled Syrup Access

A top feeder is designed for controlled feeding. When that control is lost, the feeder quickly becomes a liability for the colony. The entire purpose of your inspection is to prevent uncontrolled access, which leads to two primary dangers.

Why Drowning Is the Primary Risk

The most immediate danger of a faulty top feeder is bee drowning. If the screen covering the syrup reservoir has gaps or holes, bees will bypass the safe feeding channel. Once in the main syrup reservoir, they will quickly become trapped and drown.

The Secondary Threat: Robbing and Pests

A poorly sealed feeder can also trigger robbing. If the inner cover or telescoping lid does not sit flush, the scent of syrup can leak out. This attracts bees from other hives, who may try to force their way in to steal the food, creating a "robbing frenzy" that can decimate a weaker colony.

Your Two-Point Inspection Checklist

Your inspection should be methodical and focus on ensuring the feeder is a completely sealed unit, apart from the single, safe access point for your bees.

Point 1: Inspect the Hardware Cloth Screen

The screen is the most critical safety feature. It must be bee-tight, meaning there are absolutely no gaps large enough for a bee to squeeze through.

Carefully check the entire perimeter where the screen is attached to the feeder's wooden or plastic frame. Look for bent corners, loose staples, or corrosion that has created holes. If you find any bee-sized gaps, seal them with a beesafe silicone sealant and allow it to cure completely before use.

Point 2: Inspect the Inner Cover and Lid

The seal from above is just as important. Place the inner cover on the feeder and ensure it sits perfectly flat with no gaps. A warped inner cover is a common failure point.

Likewise, ensure your telescoping outer cover fits securely over everything. Any gap at the top is an open invitation for robber bees, ants, and yellow jackets to access the syrup from above.

Understanding the Trade-offs of Top Feeders

While effective, top feeders are not without their downsides. Understanding these helps you decide if it's the right tool for your specific situation.

Pro: Large Volume Capacity

Top feeders hold a significant amount of syrup, often one to two gallons. This makes them ideal for rapid feeding in the fall to build up winter stores or for stimulating brood production in a strong, populous hive.

Con: High Risk if Not Maintained

As detailed above, the potential for drowning bees is the single biggest drawback. This risk is almost entirely mitigated by a proper inspection, but it requires diligence from the beekeeper.

Con: Potential to Chill the Brood

In cooler weather, a large volume of cold syrup placed directly above the cluster can act as a "cold sink." This can chill the brood nest, forcing the bees to expend extra energy to maintain temperature, which can slow colony development.

Making the Right Choice for Your Goal

Use your inspection to determine if a top feeder is the appropriate tool for your colony's current needs.

- If your primary focus is rapid feeding for a strong, established colony: A well-inspected top feeder is an excellent and efficient choice.

- If your primary focus is safety for a new, small, or weak colony: The risk of chilling or drowning may outweigh the benefits, and you might consider a safer alternative like an entrance feeder or a frame feeder.

A simple two-point check transforms this tool from a potential hazard into one of the most effective assets in your apiary.

Summary Table:

| Inspection Point | What to Check | Why It's Critical |

|---|---|---|

| Hardware Cloth Screen | Check for gaps, loose staples, or corrosion. | Prevents bees from entering the reservoir and drowning. |

| Inner Cover & Lid | Ensure a flat, flush, bee-tight seal. | Prevents robbing by pests and other bees. |

Ensure your apiary is equipped with reliable, bee-safe feeding solutions. A faulty feeder can risk your entire colony. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable top feeders and wholesale beekeeping supplies designed for safety and efficiency. Let us help you protect your investment. Contact HONESTBEE today for wholesale inquiries and expert support.

Visual Guide

Related Products

- Boardman Entrance Bee Feeder Durable Galvanized Steel and Wood Construction for Beekeeping

- Professional Hive Top Bee Feeder for Beekeeping

- Professional Hive Front Entrance Bee Feeder

- Classic Boardman Entrance Bee Feeder Hive Front Feeding Solution

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

People Also Ask

- What is a bee entrance feeder and what are its drawbacks? Essential Guide to Hive Security and Feeding Efficiency

- Are entrance feeders good for bees? Prioritize Hive Health Over Convenience

- How does a bee entrance feeder work? A Simple Guide to Convenient Hive Feeding

- What types of bee feeders are available for beginners? Start with the Simple Entrance Feeder

- What is an entrance feeder and what are its characteristics? Essential Guide for Effortless Hive Feeding