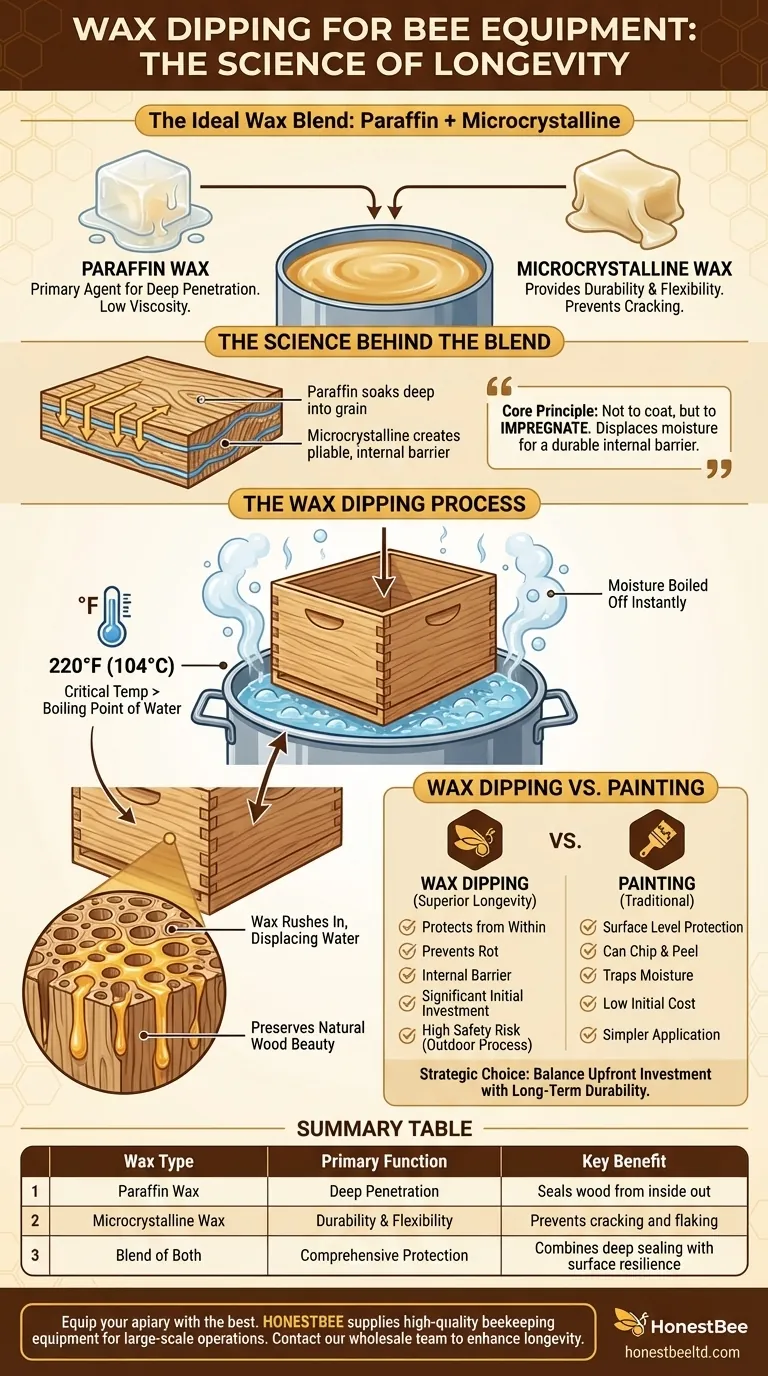

The ideal wax for dipping bee equipment is not a single type but a strategic blend of paraffin and microcrystalline wax. This specific combination is engineered to deeply penetrate and protect woodenware from the elements, far surpassing the surface-level protection of paint. The process involves submerging the equipment in this wax blend heated to a precise temperature.

The core principle of wax dipping is not to coat the wood, but to impregnate it. By using a blend of paraffin and microcrystalline wax heated above the boiling point of water, you displace all moisture from the wood fibers, creating a durable, internal barrier against the weather.

The Science Behind the Wax Blend

To understand why this method is so effective, we must look at the distinct roles each type of wax plays in the mixture. They are not interchangeable; they work in tandem to provide comprehensive protection.

The Role of Paraffin Wax

Paraffin wax is the primary agent for penetration. When heated, it has a very low viscosity, allowing it to soak deep into the wood grain. This is the key to creating a seal that protects the wood from the inside out.

The Function of Microcrystalline Wax

Microcrystalline wax provides durability and flexibility. On its own, paraffin can be brittle. The addition of microcrystalline wax creates a more pliable, resilient final product that won't crack or flake with changes in temperature and humidity.

Why the Blend is Superior

The combination offers the best of both worlds. Paraffin carries the protective properties deep into the wood, while the microcrystalline wax ensures the treatment remains stable and tough on the surface and within the fibers for years.

The Wax Dipping Process: A Deeper Look

The effectiveness of the wax blend is activated by a specific process. The temperature and technique are just as critical as the ingredients themselves.

The Critical Role of Temperature

The wax is typically heated to around 220°F (104°C). This temperature is deliberately chosen because it is just above the boiling point of water (212°F / 100°C).

Displacing Moisture for Lasting Protection

When wooden equipment is submerged in the hot wax, any residual moisture within the wood fibers is instantly boiled off. You can see this happen as bubbles rise to the surface. The melted wax then rushes in to fill these microscopic voids, effectively displacing all water.

Aesthetics and Preservation

A significant benefit of this process is that it preserves the natural beauty of the wood. Unlike paint, which covers the grain, the wax provides a clear, lasting finish that highlights the wood's original color and texture.

Understanding the Trade-offs: Wax Dipping vs. Painting

While the references note that wax dipping is superior to painting, a complete understanding requires acknowledging the practical considerations and downsides.

Superior Longevity

The primary advantage of wax dipping is its durability. By protecting from within, it prevents rot and water damage far more effectively than a surface coat of paint, which can chip, peel, and trap moisture underneath.

The Upfront Investment

Wax dipping requires a significant initial investment. You need a large vat capable of holding enough wax to submerge entire hive bodies, a powerful heat source, and a substantial quantity of the wax itself. This is far more costly than a can of primer and paint.

Safety Considerations

Working with a large volume of flammable wax heated to over 200°F presents a serious safety risk. This process must be done outdoors, away from structures, with appropriate fire suppression equipment on hand.

Making the Right Choice for Your Operation

Choosing between wax dipping and painting depends entirely on the scale of your operation and your long-term goals.

- If your primary focus is maximum longevity and minimal long-term maintenance: Wax dipping is the definitive choice for its deep-penetrating, long-lasting protection.

- If your primary focus is low initial cost and simplicity for a small number of hives: Traditional painting remains a viable, though less durable, alternative that requires more frequent upkeep.

Ultimately, selecting the right protection method is a strategic decision that balances upfront investment with the long-term health and durability of your beekeeping equipment.

Summary Table:

| Wax Type | Primary Function | Key Benefit |

|---|---|---|

| Paraffin Wax | Deep Penetration | Seals wood from the inside out |

| Microcrystalline Wax | Durability & Flexibility | Prevents cracking and flaking |

| Blend of Both | Comprehensive Protection | Combines deep sealing with surface resilience |

Equip your apiary with the best. For commercial beekeepers and distributors, the long-term durability of wax-dipped equipment is a sound investment. HONESTBEE supplies the high-quality beekeeping equipment and supplies needed for large-scale, efficient operations. Contact our wholesale team today to discuss how our products can enhance the longevity and productivity of your beekeeping business.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Wooden Bee Brush with Triple Row Artificial Fiber for Beekeeping

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- Why is it important to compare the progress of different hives? A Beekeeper's Key Diagnostic Tool

- What are the basic tools for beekeeping? Essential Starter Kit for Safe & Successful Hive Management

- What are the primary functions of a stainless steel hive tool? Essential Equipment for Professional Beekeeping

- What is the hole in a hive tool for? A Multi-Tool for Apiary Repairs and Maintenance

- How does the hive splitting process contribute to colony management? Master Your Apiary Recovery Strategies