For beekeepers planning to scale up or enter commercial operations, the Layens and top bar hives are generally not recommended. Their designs, while excellent for other purposes, introduce significant inefficiencies in labor, equipment standardization, and honey processing that become major obstacles when managing a large number of colonies. The industry standard, the Langstroth hive, was specifically designed to solve these scalability challenges.

The choice of a beehive is not about "good" vs. "bad," but about aligning the tool with the job. Commercial beekeeping prioritizes efficiency and standardization above all else, making the Langstroth hive the default, whereas other hives prioritize different goals like natural comb or ease of lifting for the hobbyist.

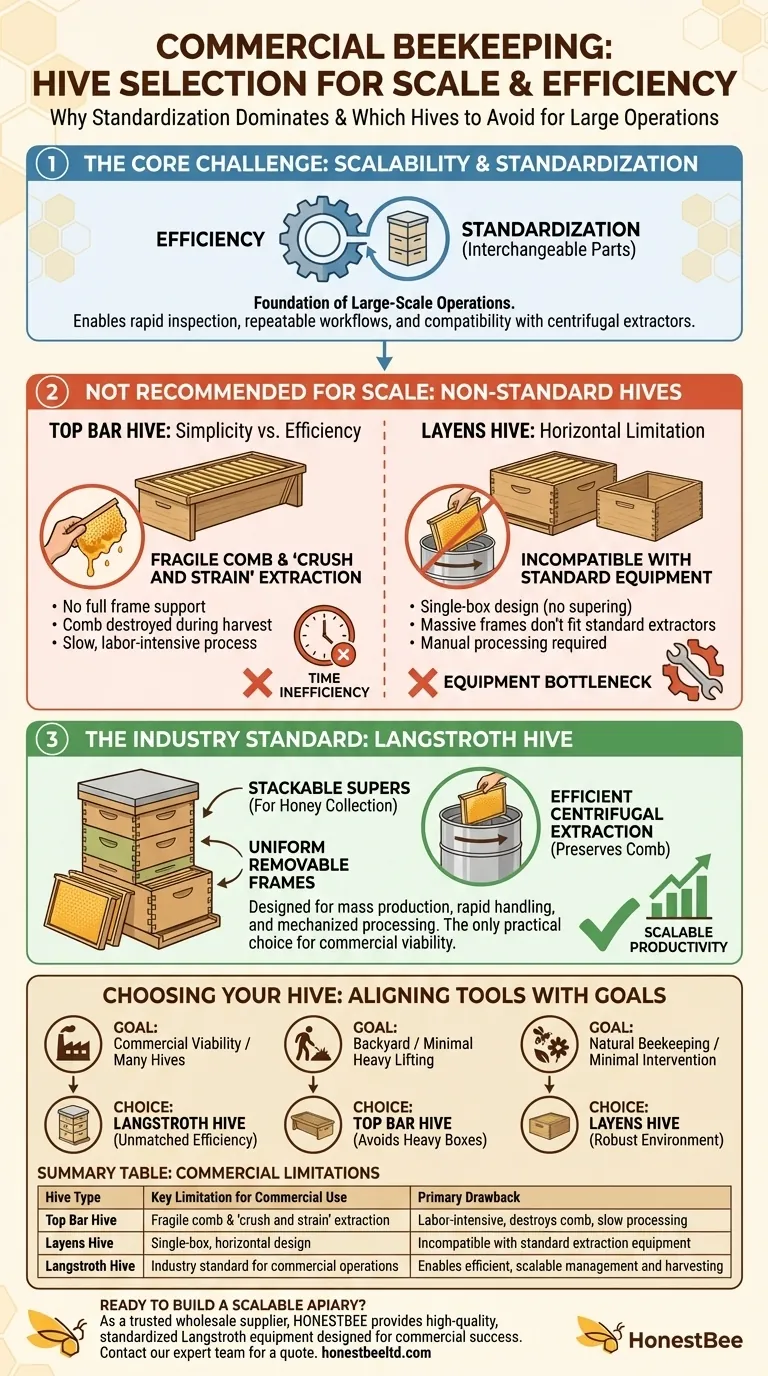

Why Standardization Dominates Commercial Beekeeping

The foundation of any large-scale agricultural operation, including beekeeping, is efficiency. In this context, efficiency is achieved through standardization—the ability to use interchangeable parts across the entire operation.

The Langstroth Advantage: A System Built for Scale

The Langstroth hive, developed in the 1850s, revolutionized beekeeping for this very reason. Its system of uniform, stackable boxes (supers) and removable frames allows for rapid inspection, manipulation, and honey harvesting.

Because every frame fits in every box and every box fits on every hive, a beekeeper can manage hundreds or thousands of hives with a predictable, repeatable workflow. This design is also built to work with centrifugal honey extractors, which can process dozens of frames at once without destroying the delicate beeswax comb.

The Challenges of Non-Standard Hives at Scale

Hives that deviate from the Langstroth model present logistical hurdles that are manageable for a few backyard colonies but become crippling at a commercial level.

The Top Bar Hive: Simplicity vs. Efficiency

The top bar hive is a single, long box where bees build their comb directly down from simple wooden bars. While elegantly simple, this design creates several commercial bottlenecks.

The comb is not supported by a full frame, making it extremely fragile and difficult to inspect quickly. More importantly, honey extraction is typically done by cutting the comb off the bar and using a "crush and strain" method. This process is slow, labor-intensive, and destroys the comb, forcing the bees to expend significant energy rebuilding it every season.

The Layens Hive: A Horizontal Limitation

The Layens hive uses very large, deep frames housed in a single horizontal box. It is an excellent design for overwintering bees and is popular among beekeepers who want to minimize hive intervention.

However, its single-box, horizontal format is not conducive to the simple "supering" (adding boxes) used for honey collection in Langstroth hives. Furthermore, its massive frames are not compatible with the standard extraction equipment that forms the backbone of commercial honey processing.

Understanding the Critical Trade-offs

Choosing a non-standard hive for a large-scale operation means accepting significant trade-offs in efficiency, cost, and logistics.

Labor and Time Inefficiency

The primary cost in commercial beekeeping is labor. The time spent carefully handling fragile top bar combs or managing non-standard Layens frames adds up dramatically across dozens or hundreds of hives. Crush-and-strain honey extraction is simply not viable from a time-cost perspective compared to centrifugal extraction.

Equipment Sourcing and Cost

Langstroth components are mass-produced, readily available, and relatively inexpensive. Sourcing or building hundreds of specialized top bar or Layens hives creates a significant logistical and financial burden. Finding compatible processing equipment is nearly impossible, forcing the beekeeper into inefficient manual methods.

Different Goals, Different Tools

It is crucial to understand that top bar and Layens hives are not "bad" hives. They are exceptional tools for their intended purpose, which often includes natural beekeeping, minimal heavy lifting, or producing whole-comb honey on a small scale. Their design simply serves a different master than the commercial operator's need for speed and volume.

Choosing the Right Hive for Your Ambition

Your long-term goals should be the deciding factor in your initial equipment investment. Moving an established apiary from one hive system to another is a difficult and expensive process.

- If your primary focus is commercial viability or managing many hives: The Langstroth hive is the only practical choice due to its unmatched efficiency and universally standard equipment.

- If your primary focus is backyard beekeeping with minimal heavy lifting: A top bar hive is an excellent option that avoids the need to lift heavy honey-filled boxes.

- If your primary focus is natural beekeeping with minimal interventions: The Layens hive offers a robust environment that allows the colony to function with less management.

Understanding these fundamental design trade-offs empowers you to build an apiary that aligns perfectly with your long-term goals.

Summary Table:

| Hive Type | Key Limitation for Commercial Use | Primary Drawback |

|---|---|---|

| Top Bar Hive | Fragile comb & 'crush and strain' extraction | Labor-intensive, destroys comb, slow processing |

| Layens Hive | Single-box, horizontal design | Incompatible with standard extraction equipment |

| Langstroth Hive | Industry standard for commercial operations | Enables efficient, scalable management and harvesting |

Ready to build a scalable, efficient apiary?

As a trusted wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the high-quality, standardized Langstroth equipment you need to succeed. Our durable hive components and accessories are designed for the rigors of large-scale beekeeping, helping you maximize productivity and profitability.

Contact our expert team today to discuss your commercial beekeeping equipment needs and request a wholesale quote.

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Multi-Function Plier-Style Frame Grip Hive Tool

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

People Also Ask

- Which Langstroth box configurations are recommended for beekeepers seeking to reduce lifting weight? Ergonomic Solutions

- What are the advantages of standard Langstroth movable-frame beehives? Boost Honey Yields by 1.8x

- How does the orientation of the hive sides benefit comb construction? Ensure Straight, Movable Combs for Easier Hive Management

- Should a beginner try a different type of hive? Start with a Langstroth for a solid foundation.

- How does the ease of access differ between 8-frame and 10-frame hives? Choose the Right Hive for Your Body