To successfully mold beeswax, you need a container that can withstand the heat and allow for easy release of the cooled wax. The most common and effective choices are flexible, food-grade silicone molds, such as cake or muffin pans and specialty soap molds, but even simple items like rinsed cardboard milk cartons can be used for basic blocks.

The best mold for beeswax combines two key properties: sufficient heat resistance to safely hold the molten wax and enough flexibility to release the wax easily once it has cooled and contracted.

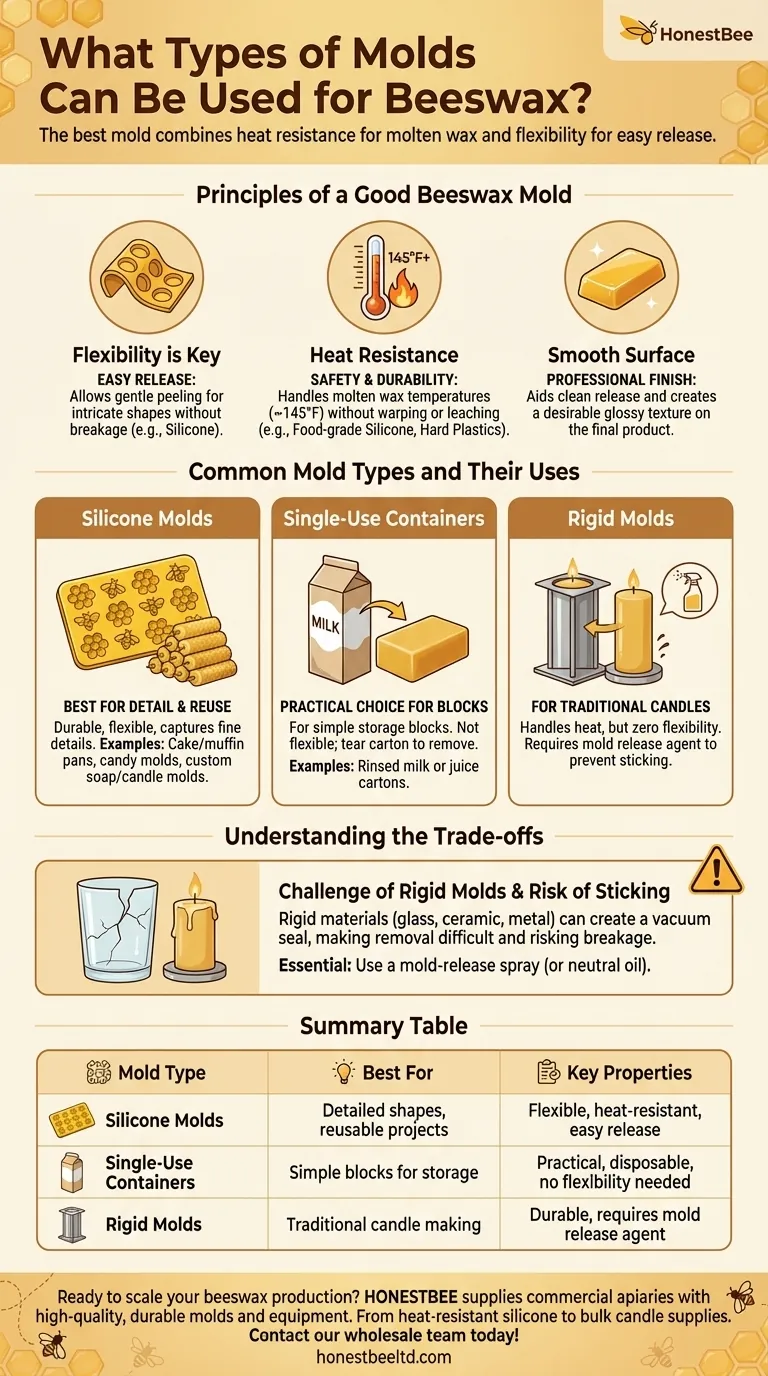

The Principles of a Good Beeswax Mold

Choosing the right mold is less about a specific brand and more about understanding the physical properties of the material you're using. Molten beeswax behaves in predictable ways, and the right mold works with those behaviors, not against them.

Flexibility is Key for Easy Release

Beeswax shrinks slightly as it cools. This contraction is helpful, as it naturally pulls the wax away from the sides of the mold.

A flexible material like silicone allows you to gently peel the mold away from the finished beeswax piece, making it the ideal choice for intricate or detailed shapes without the risk of breakage.

Heat Resistance Ensures Safety and Durability

Beeswax melts at approximately 145°F (63°C). Your mold must be able to handle this temperature without melting, warping, or leaching unwanted chemicals into your wax.

This is why food-grade silicone is highly recommended. It's designed for high oven temperatures, making it perfectly safe for hot beeswax. Hard plastics designed specifically for candlemaking are also suitable.

A Smooth Surface Creates a Professional Finish

The texture of your mold's interior surface will be imprinted directly onto your finished beeswax product.

A smooth, non-porous surface not only aids in a clean release but also gives the final beeswax bar or candle a desirable glossy finish.

Common Mold Types and Their Uses

You can use a variety of household and specialty items for molding beeswax, each with its own advantages.

Silicone Molds: The Best for Detail and Reuse

Silicone is the gold standard for most beeswax projects. It's durable, flexible, and captures fine details exceptionally well.

Examples include cake pans, muffin trays, candy molds, and custom soap or candle molds with shapes like honeycombs or bees.

Single-Use Containers: The Practical Choice for Blocks

For simple, functional blocks of wax for storage or future projects, you don't need anything fancy.

Clean, rinsed cardboard milk or juice cartons work perfectly. Because they are not flexible, you simply tear the carton away to remove the solid block of wax.

Understanding the Trade-offs

While many materials can work, some present challenges that are important to anticipate to avoid frustration and wasted material.

The Challenge of Rigid Molds

Materials like glass, ceramic, or metal can easily handle the heat of molten wax. However, they have zero flexibility.

As the wax shrinks, it can create a powerful vacuum seal, making it extremely difficult to remove the final piece without shattering the container or breaking the wax. If you must use a rigid mold, a mold-release spray is essential.

The Risk of Sticking

Even with a good mold, wax can sometimes stick, especially in highly detailed areas or if the mold is not perfectly clean.

A very light coating of a neutral oil (like vegetable oil) or a commercial mold release agent can act as a safety measure, though it is often unnecessary with high-quality silicone.

Making the Right Choice for Your Project

Your goal determines the best tool for the job. To select the right mold, consider what you are trying to create.

- If your primary focus is creating detailed, reusable shapes like guest soaps or small ornaments: High-quality silicone molds are your best investment.

- If your primary focus is processing raw beeswax into simple, storable blocks: Use single-use containers like rinsed milk cartons for a no-fuss, practical solution.

- If your primary focus is making traditional pillar or taper candles: Look for specialized rigid plastic or metal candle molds, but be prepared to use a mold release agent.

Ultimately, the ideal mold provides a safe vessel for the hot wax and a simple path to a clean, well-formed result.

Summary Table:

| Mold Type | Best For | Key Properties |

|---|---|---|

| Silicone Molds | Detailed shapes, reusable projects | Flexible, heat-resistant, easy release |

| Single-Use Containers (e.g., cardboard cartons) | Simple blocks for storage | Practical, disposable, no flexibility needed |

| Rigid Molds (e.g., metal, plastic) | Traditional candle making | Durable, requires mold release agent |

Ready to scale your beeswax production with professional-grade supplies?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, durable molds and equipment needed for efficient, large-scale operations. From heat-resistant silicone molds to bulk candle-making supplies, we provide the reliable tools that help your business thrive.

Contact our wholesale team today to discuss your specific needs and request a catalog!

Visual Guide

Related Products

- 3D Square Honeycomb Pillar Silicone Candle Molds for Making Beeswax Candles

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- 6-Cavity Bee Floral Themed Silicone Soap Mold for Handmade Soap Making

- Hexagonal Bee Honeycomb Silicone Soap Mold by HONESTBEE

- 3D Beehive Silicone Skep Wax Candle Molds for Candles

People Also Ask

- Why are beeswax candles expensive? The True Cost of Natural Bee Labor

- What are the technical benefits of using mold casting processes in candle manufacturing? Achieve Precision & Consistency

- What is the economic value of using candle-making equipment and beeswax consumables? Maximize Your Apiary Profits

- What are the technical differences between the dipping and pouring methods in beeswax candle manufacturing? - Guide

- How do you remove a finished candle from the mold? Master the Art of Flawless Demolding